CONTACT US

Product Overview

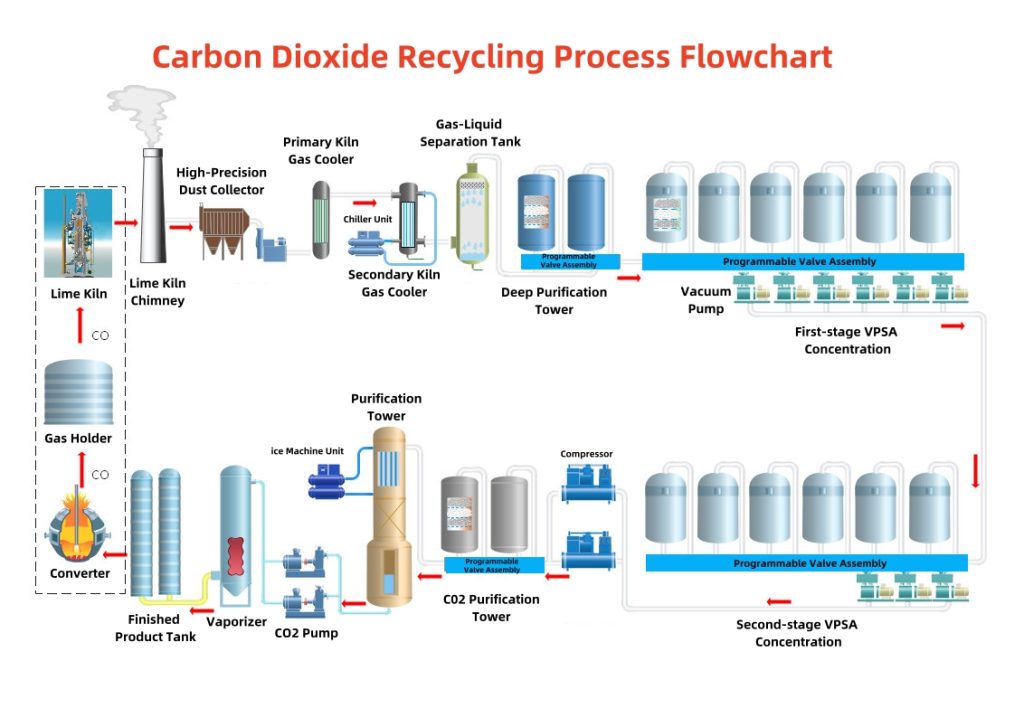

The VPSA (Vacuum Pressure Swing Adsorption) Carbon Dioxide Recovery Equipment is specifically designed for the efficient extraction of carbon dioxide from low-temperature, high-dust, and low CO₂ content flue gases generated by lime kilns. The process flow includes multiple stages such as flue gas deep purification, VPSA concentration, CO₂ compression, purification, liquefaction, and storage, ensuring high purity and stability of the final product. This advanced technology effectively reduces production costs and enhances safety, making it suitable for various industrial applications.

Product Features

- High-Precision Dust Removal and Cooling: Utilizes a process that combines high-precision dust removal followed by cooling, preventing blockages in coolers caused by dust accumulation and ensuring stable equipment operation.

- Deep Purification: Equipped with a TSA (Temperature Swing Adsorption) deep purification unit that effectively removes moisture, NOx, and SO₂, reducing the risk of equipment corrosion and prolonging the lifespan of the adsorbents.

- Energy-Efficient Design: The low-pressure adsorption process minimizes energy consumption and investment costs while optimizing the footprint of the equipment.

- High-Purity Output: The product purity can reach industrial-grade premium standards (≥99.8%), ensuring compliance with various application requirements.

- Low-Temperature Liquefaction: Employs low-temperature liquefaction and purification processes to ensure high purity and recovery efficiency of CO₂.

- Cooling Energy Recovery: Takes full advantage of cooling energy recovery and non-condensable gas pressure relief to further reduce energy consumption.

- Circulating Water System: Utilizes a circulating water system throughout the equipment to ensure stable production of liquid CO₂ during winter and nighttime operations.

Applications

- Metallurgical Industry: Recovers and reuses CO₂ from flue gases, contributing to the reduction of greenhouse gas emissions.

- Cement Plants: Extracts CO₂ from lime kiln flue gases, meeting production and environmental protection requirements.

- Chemical Industry: Provides high-purity CO₂ as a reaction raw material.

- Agriculture: Used for controlling greenhouse gases and promoting plant growth.

- Food Processing: Serves as food-grade CO₂ for preservation and packaging applications.

woboenerkeco

woboenerkeco