CONTACT US

Technology Overview

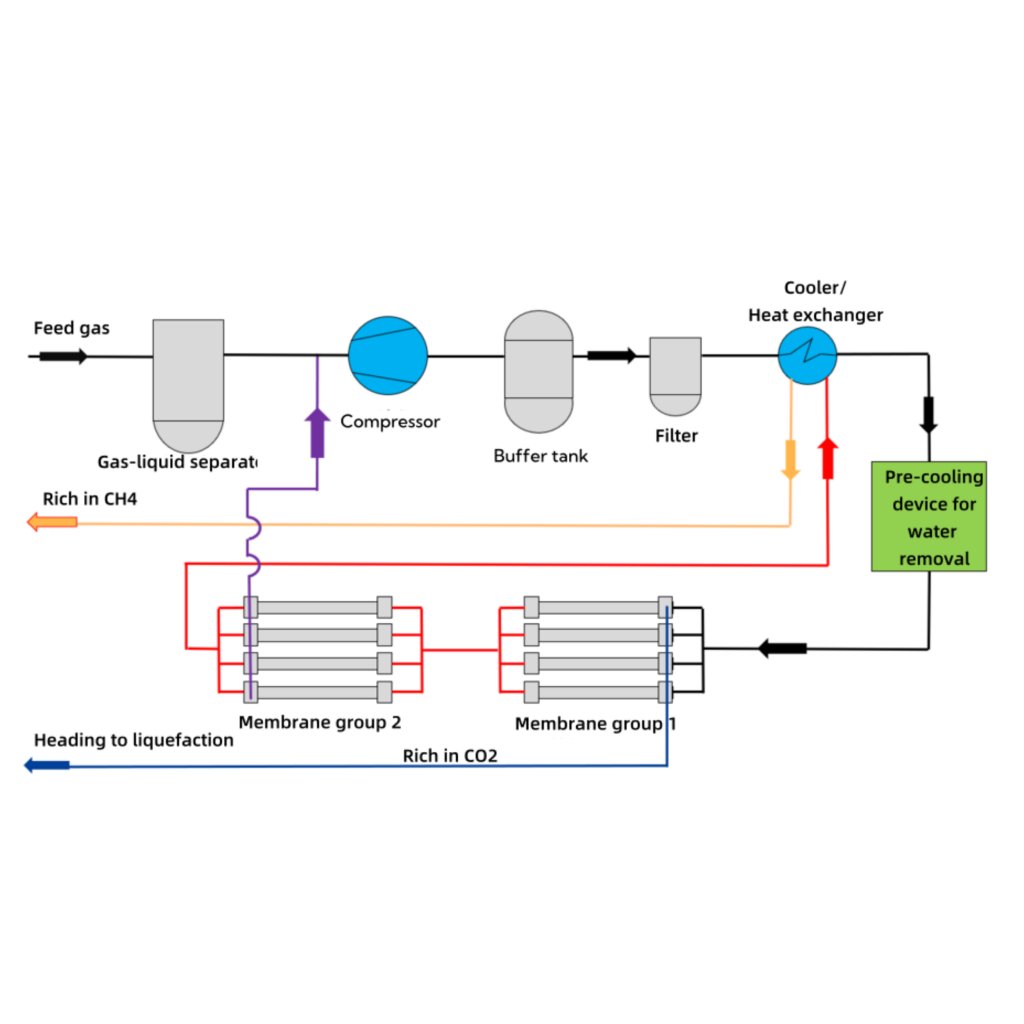

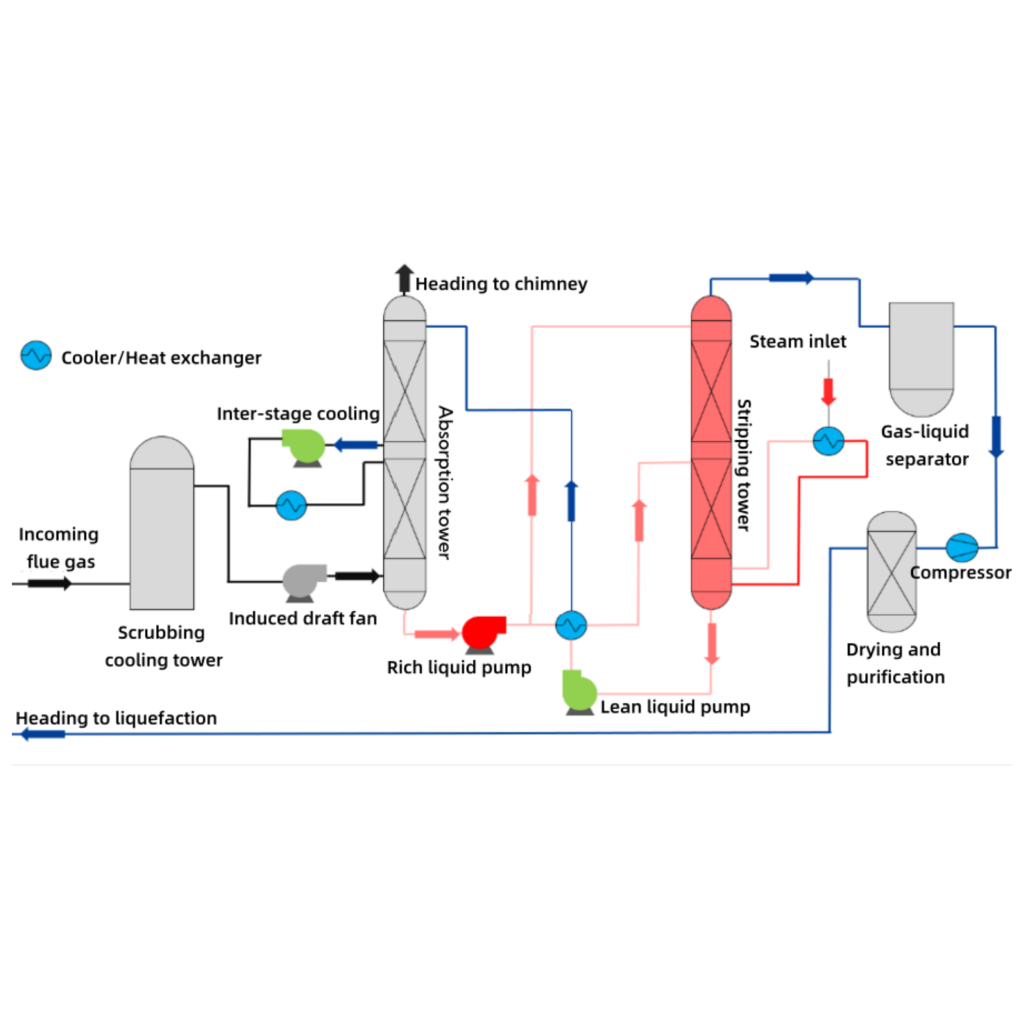

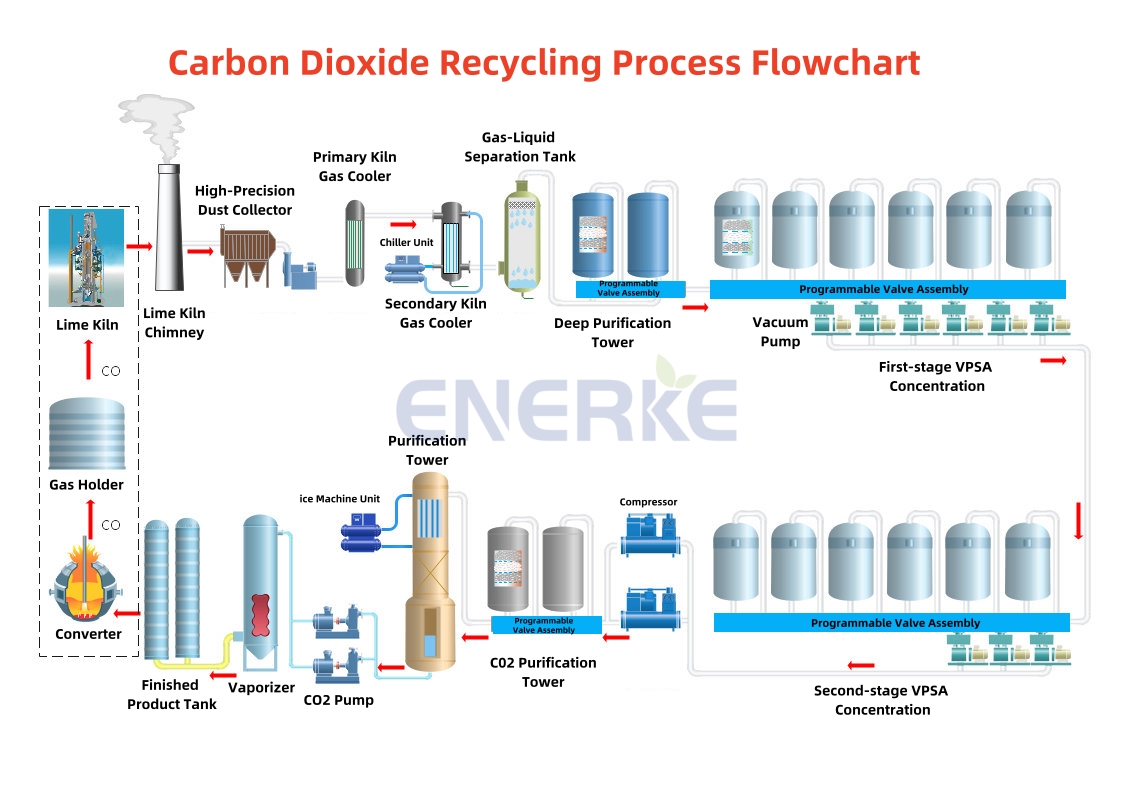

Industrial flue gas CO₂ capture technology is specifically designed for optimizing the treatment of flue gases from high-temperature, low-pressure processes such as rotary kilns (lime kilns). These gases typically have low CO₂ concentrations and contain impurities like NOx and SO₂. The process includes multiple stages: deep flue gas purification, two-stage VPSA (Vacuum Pressure Swing Adsorption) concentration, CO₂ compression, purification, liquefaction, and storage, all aimed at efficiently recovering and purifying CO₂ from industrial flue gases.

Product Features

- Efficient Dust Removal and Cooling: Utilizes a high-precision dust removal and cooling process to effectively prevent dust blockage in traditional coolers, ensuring long-term stable operation of the equipment.

- Deep Purification Unit: Incorporates a TSA (Temperature Swing Adsorption) unit for deep purification, effectively removing moisture, NOx, and SO₂, which reduces corrosion risks and extends the lifespan of the main adsorbent.

- Energy-Efficient Design: Low-pressure adsorption technology and a blower-free design minimize the number of moving parts, reducing energy consumption and footprint.

- High-Purity CO₂: The two-stage VPSA concentration process ensures that the final industrial-grade product achieves a purity of ≥99.8%.

- Low-Temperature Liquefaction Process: Employs low-temperature liquefaction and purification technology to recover cold energy, lowering energy consumption while ensuring CO₂ purity.

- Recycling Water System: Features a complete recycling water system that addresses low production capacity in winter and at night, ensuring stable operation.

Applications

- Cement and Lime Industries: Suitable for flue gas treatment and CO₂ recovery in cement and lime sectors, meeting environmental regulations.

- Chemical Industry: Effectively recovers CO₂ during chemical production, supporting clean production and resource recycling.

- Environmental Technology: Provides technical support for emission reduction and carbon capture projects, contributing to the achievement of low-carbon economy goals.

Enerke Low Carbon Tech Corp

Enerke Low Carbon Tech Corp