CONTACT US

Product Overview

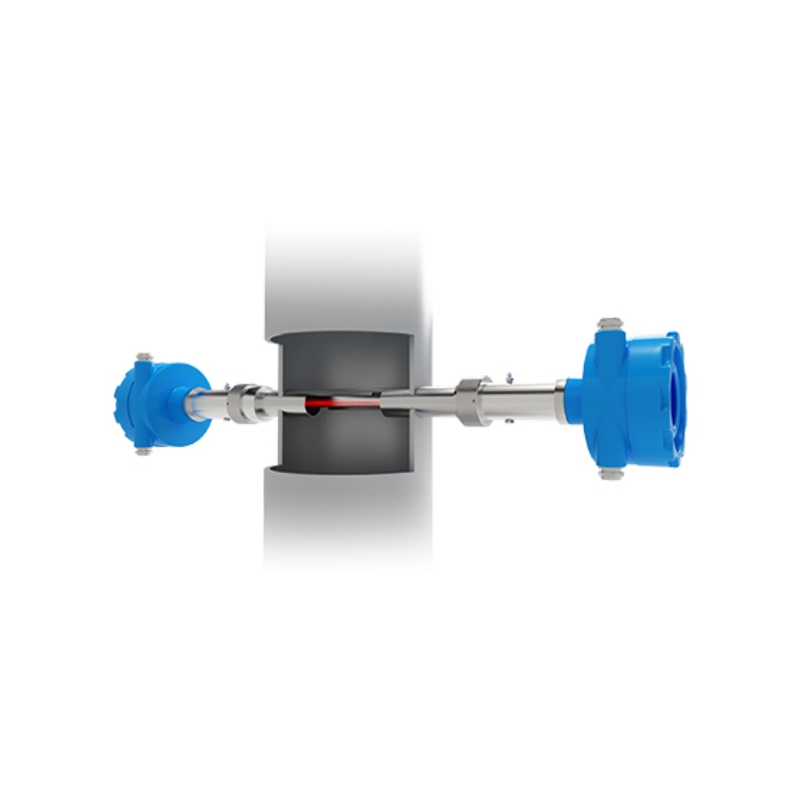

The In-Situ Laser Process Gas Analyzer (Cross-Beam Type) is a high-performance gas analyzer based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) technology, designed for precise gas control in industrial processes. Using a cross-beam structure, it enables rapid and accurate in-situ gas concentration measurement, particularly suited to complex industrial environments. With an ultra-fast response time (T90 ≤ 1 second), it avoids the delays typical in sampling-based measurements, ensuring real-time and accurate results.

Key Features

- High-Precision TDLAS Technology: Measures target gases without interference from background gases, ensuring accurate readings.

- In-Situ Design: Eliminates the need for sampling and pretreatment systems, reducing installation and maintenance costs.

- Rapid Response: T90 response time under 1 second, allowing adaptation to dynamic changes in gas concentration.

- Real-Time Online Measurement: Minimizes gas concentration distortion, ensuring reliable data.

- Adaptable to Harsh Environments: Operates stably in high-temperature, high-dust, high-humidity, corrosive, and high-flow environments.

- High Safety: Explosion-proof design, ideal for environments requiring high safety standards.

- Low Maintenance: Simple structure with no moving or consumable parts, allowing for long-term maintenance-free operation.

Applications

- Petrochemical Industry: Real-time monitoring of gas components in refining processes to ensure safety and efficiency.

- Coal Chemical Industry: Monitors gas concentrations in high-temperature, high-dust environments, aiding in precision control.

- Metallurgy: Tracks gas concentrations during production to improve energy efficiency and reduce emissions.

- Environmental Monitoring: Monitors waste gas components in real-time to support compliance with emission standards.

- Power Generation: Measures gases in combustion processes to enhance efficiency and control emissions.

| Parameter | Description |

| Measured Components | H2S, O2, CO, CO2, CH4* |

| Measurement Principle | TDLAS |

| Measurement Range | H2S: 0 ~ 100ppm, 0 ~ 5000ppm |

| O2: (0 ~ 5)%VOL (customizable up to 100%) | |

| CO: (0 ~ 100)%VOL | |

| CO2: (0 ~ 100)%VOL | |

| CH4: (0 ~ 20)%VOL | |

| Accuracy | ≤±1%F.S. |

| Repeatability | ≤±1% |

| Range Drift | ≤±1%F.S. |

| Resolution | 0.01%VOL |

| Response Time | T90≤1s |

| Operating Parameters | |

| Explosion-proof Rating | Ex d ⅡC T6 Gb |

| Installation Mode | In-situ installation |

| Ambient Temperature | (-20 ~ +60)℃ |

| Power Supply | 24V DC, 24W |

| Purge Gas | (0.3~ 0.8) MPa industrial nitrogen |

| Interface Signal | |

| Communication | RS485, RS232 |

| Output Mode | 2 x 4-20mA outputs |

| 3 relay outputs |

woboenerkeco

woboenerkeco