CONTACT US

Product Overview

The Hydrogen Targeted Purification System utilizes multi-column pressure swing adsorption (PSA) technology to purify hydrogen from hydrogen-rich sources through a highly automated process. With a compact design and small footprint, this system is ideal for industrial gas separation needs requiring high-purity hydrogen. Leveraging years of PSA research and application experience, it offers a mature and stable hydrogen purification solution, along with support for system upgrades.

Technical Features

- High Efficiency and Automation: Fully automated system allows for unmanned operation.

- Compact Layout: Space-saving design with a compact layout, adaptable to various installation environments.

- Stable Continuous Operation: Supports year-round continuous operation without the need for shutdown maintenance.

- Flexible Load Adjustment: Safe load adjustment from 30% to 100% of flow capacity.

- Proprietary Adsorbents and Valves: Uses proprietary adsorbents and pneumatic plate control valves for high adsorption efficiency, excellent sealing, and long service life.

Process Flow

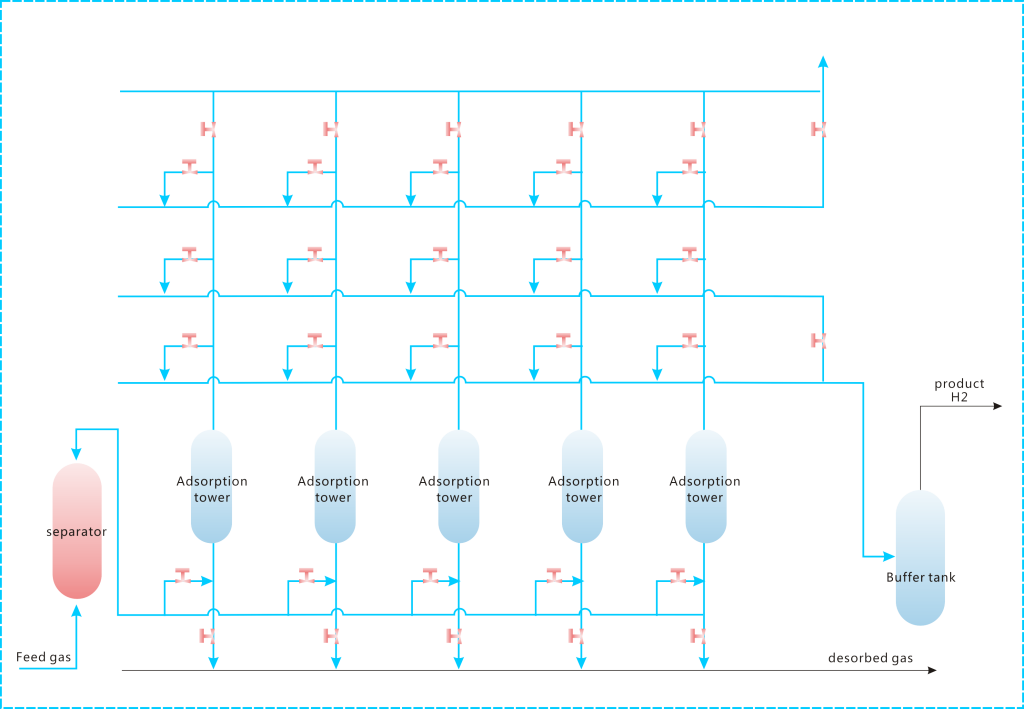

The system uses a multi-column PSA process for hydrogen purification, involving stages such as adsorption, depressurization, desorption, and repressurization. Multiple adsorption columns operate in staggered steps, forming a closed-loop cycle to ensure continuous input of feed hydrogen and stable output of product hydrogen.

Application Areas

- Industrial Hydrogen Production: Suitable for hydrogen purification in industries like chemical processing and metallurgy.

- New Energy: Meets the high-purity hydrogen requirements of fuel cells and other new energy applications.

- Gas Recovery: Ideal for purifying hydrogen from industrial by-product gases, enhancing resource utilization.

| Device Capacity | 10~300000Nm3/h |

| Purity | 99%~99.9995%(V/V) |

| Pressure | 0.4~5.0Mpa(G) |

woboenerkeco

woboenerkeco