CONTACT US

Product Overview

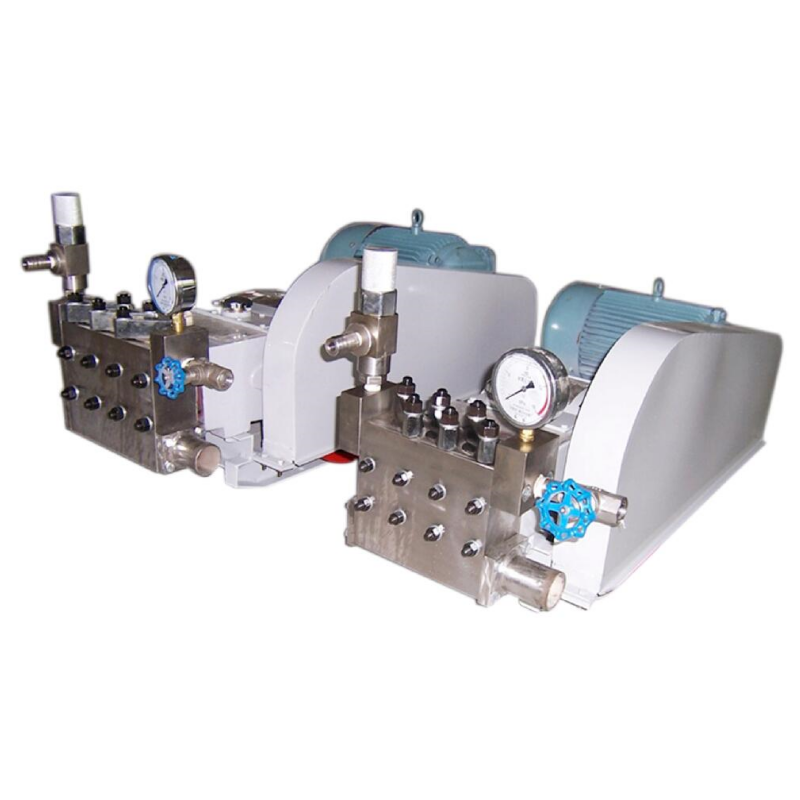

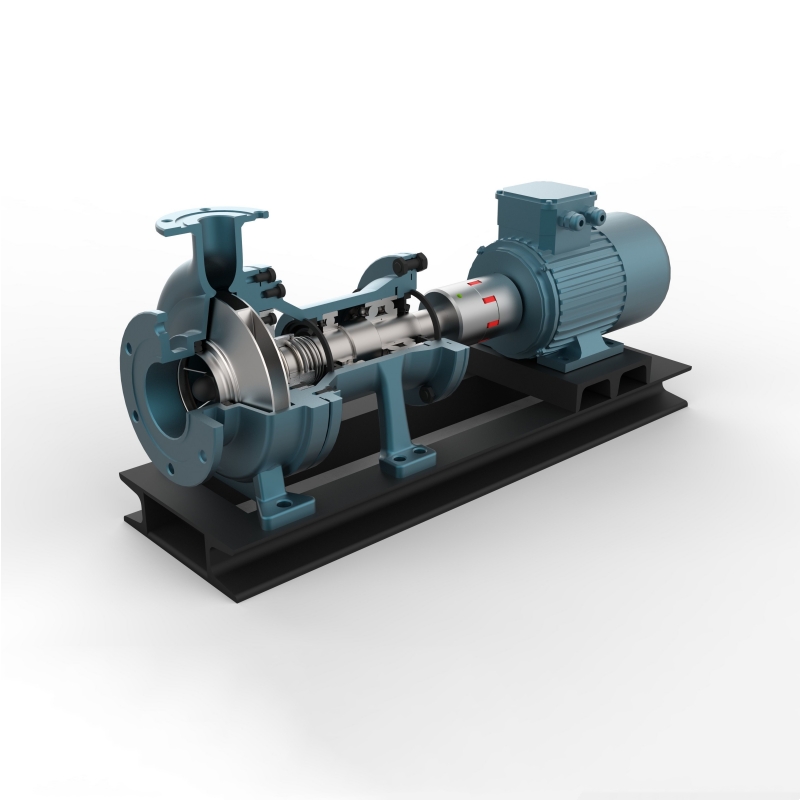

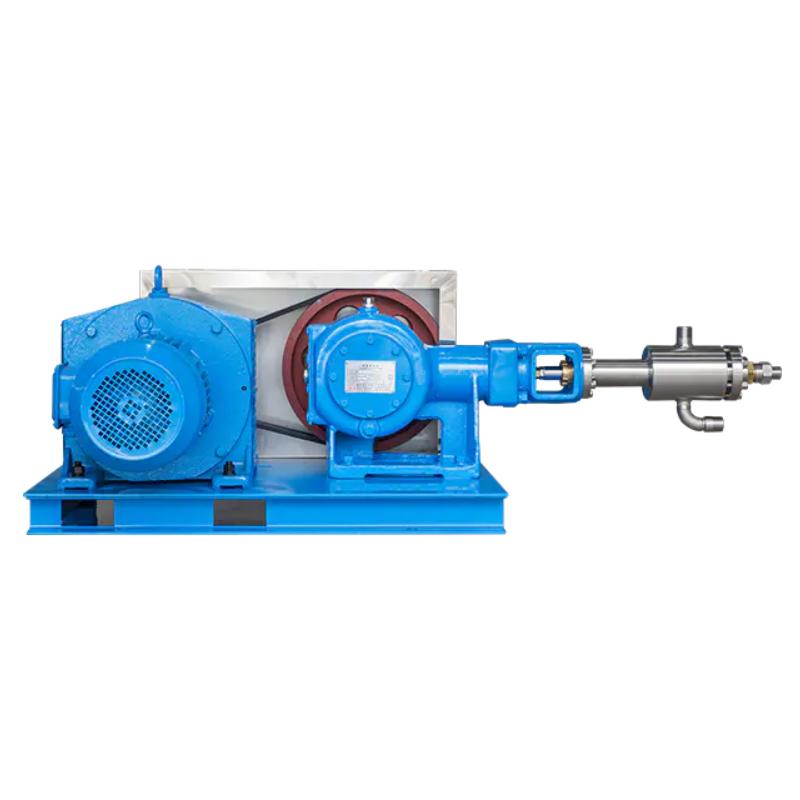

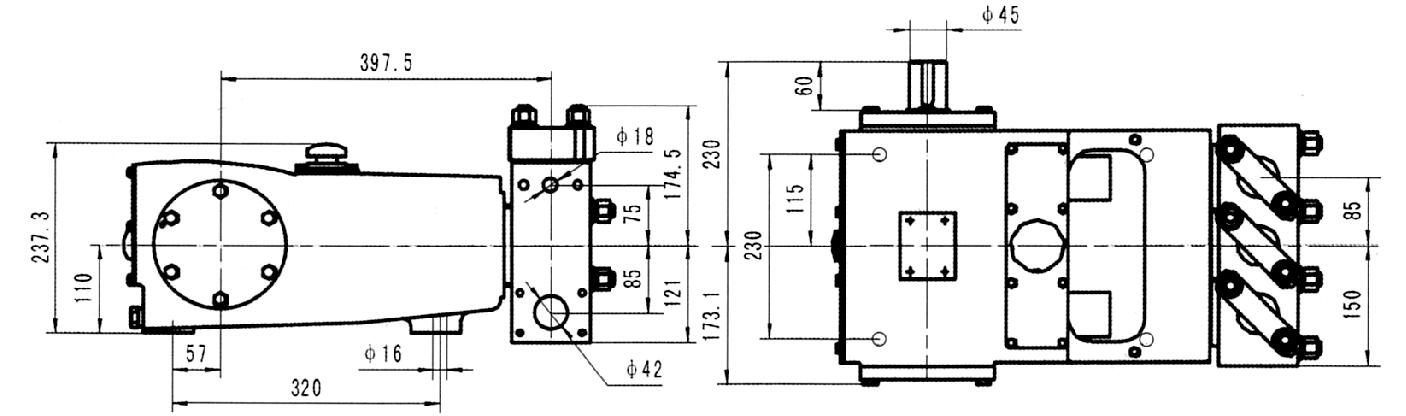

The high-pressure liquid carbon dioxide plunger pump is a versatile, high-pressure pump designed for various industrial applications, including pressure testing, cleaning, and membrane separation for hydrogen extraction. This pump offers multiple assembly configurations—horizontal, vertical, fixed, and mobile—making it suitable for diverse working environments and needs. With its adjustable pressure and flow design, the high-pressure liquid carbon dioxide plunger pump can meet specific customer requirements.

Product Features

- Versatile Applications: Suitable for various uses, including pressure testing pumps, cleaning pumps, process pumps, methanol washing pumps, and membrane separation hydrogen extraction pumps.

- Flexible Assembly Options: Available in horizontal, vertical, fixed, and mobile configurations for convenience in different settings.

- Multiple Drive Options: Supports electric motors, diesel engines, gearboxes, and pulleys, adapting to a variety of operational demands.

- Safety Pressure Regulation: Each pump is equipped with a safety pressure relief valve, ensuring safe operation under various pressure conditions.

- Adjustable Flow Rate: Flow rate can be flexibly adjusted through electromagnetic speed control, frequency conversion, or changing plunger diameters to meet specific user selection requirements.

- Durable Materials: The pump body can be made from alloy steel, martensitic, austenitic stainless steel, 316, 316L duplex steel, ensuring corrosion resistance and long service life.

Applications

- Pressure Testing and Cleaning: Ensures efficient liquid delivery during pressure testing and cleaning of equipment and pipelines.

- Chemical Processes: Utilized in methanol washing and membrane separation for hydrogen extraction in chemical processing applications.

- Food Industry: Applied in food homogenization and processing detergent slurries, meeting food safety standards.

- Industrial Processes: Suitable for any industrial processes requiring high-pressure liquid delivery.

| Pump Thrust:1200kg | Pump Stroke:40mm | Pump Weight:157kg | |||||||||||

| 3LP40 Triplex Plunger Pump Performance Parameters | |||||||||||||

| Plunger Diameter (mm) | 60 | 55 | 50 | 43 | 35 | 30 | 27 | 24 | 22 | 19 | 17 | 15 | |

| Working Pressure (MPa) | 2 | 4 | 6 | 8 | 12 | 16 | 20 | 25 | 30 | 40 | 50 | 60 | |

| Pump Speed (min) | Flow RateL/min M3/h;Power KW | ||||||||||||

| 90 | L/min | 30.52 | 25.65 | 21.2 | 15.68 | 10.39 | 7.63 | 6.18 | 4.88 | 4.1 | 3.06 | 2.45 | 1.91 |

| M3/h | 1.83 | 1.54 | 1.27 | 0.94 | 0.62 | 0.46 | 0.37 | 0.29 | 0.25 | 0.18 | 0.15 | 0.11 | |

| Kw | 1.22 | 2.05 | 2.54 | 2.51 | 2.49 | 2.44 | 2.47 | 2.44 | 2.46 | 2.45 | 2.45 | 2.29 | |

| 120 | L/min | 40.69 | 34.19 | 28.26 | 20.9 | 13.85 | 10.17 | 8.24 | 6.51 | 5.47 | 4.08 | 3.27 | 2.54 |

| M3/h | 2.44 | 2.05 | 1.7 | 1.25 | 0.83 | 0.61 | 0.49 | 0.39 | 0.33 | 0.24 | 0.2 | 0.15 | |

| Kw | 1.63 | 2.74 | 3.39 | 3.34 | 3.32 | 3.26 | 3.3 | 3.26 | 3.28 | 3.26 | 3.27 | 3.05 | |

| 140 | L/min | 47.48 | 39.89 | 32.97 | 24.38 | 16.16 | 11.87 | 9.61 | 7.6 | 6.38 | 4.76 | 3.81 | 2.97 |

| M3/h | 2.85 | 2.39 | 1.98 | 1.46 | 0.97 | 0.71 | 0.58 | 0.46 | 0.38 | 0.29 | 0.23 | 0.18 | |

| Kw | 1.9 | 3.19 | 3.96 | 3.9 | 3.88 | 3.8 | 3.85 | 3.8 | 3.83 | 3.81 | 3.81 | 3.56 | |

| 160 | L/min | 54.26 | 45.59 | 37.68 | 27.87 | 18.46 | 13.56 | 10.99 | 8.68 | 7.29 | 5.44 | 4.36 | 3.39 |

| M3/h | 3.26 | 2.74 | 2.26 | 1.67 | 1.11 | 0.81 | 0.66 | 0.52 | 0.44 | 0.33 | 0.26 | 0.2 | |

| Kw | 2.17 | 3.65 | 4.52 | 4.46 | 4.43 | 4.34 | 4.39 | 4.34 | 4.38 | 4.35 | 4.36 | 4.07 | |

| 220 | L/min | 74.61 | 62.69 | 51.81 | 38.32 | 25.39 | 18.65 | 15.11 | 11.94 | 10.03 | 7.48 | 5.99 | 4.66 |

| M3/h | 4.48 | 3.76 | 3.11 | 2.3 | 1.52 | 1.12 | 0.91 | 0.72 | 0.6 | 0.45 | 0.36 | 0.28 | |

| Kw | 2.98 | 5.02 | 6.22 | 6.13 | 6.09 | 5.97 | 6.04 | 5.97 | 6.02 | 5.99 | 5.99 | 5.6 | |

| 300 | L/min | 101.74 | 85.49 | 70.65 | 52.25 | 34.62 | 25.43 | 20.6 | 16.28 | 13.68 | 10.2 | 8.17 | 6.36 |

| M3/h | 6.1 | 5.13 | 4.24 | 3.14 | 2.08 | 1.53 | 1.24 | 0.98 | 0.82 | 0.61 | 0.49 | 0.38 | |

| Kw | 4.07 | 6.84 | 8.48 | 8.36 | 8.31 | 8.14 | 8.24 | 8.14 | 8.21 | 8.16 | 8.17 | 7.63 | |

| 350 | L/min | 118.69 | 99.73 | 82.43 | 60.96 | 40.39 | 29.67 | 24.04 | 18.99 | 15.96 | 11.9 | 9.53 | 7.42 |

| M3/h | 7.12 | 5.98 | 4.95 | 3.66 | 2.42 | 1.78 | 1.44 | 1.14 | 0.96 | 0.71 | 0.57 | 0.45 | |

| Kw | 4.75 | 7.98 | 9.89 | 9.75 | 9.69 | 9.5 | 9.61 | 9.5 | 9.57 | 9.52 | 9.53 | 8.9 | |

| 400 | L/min | 135.65 | 113.98 | 94.2 | 69.67 | 46.16 | 33.91 | 27.47 | 21.7 | 18.24 | 13.6 | 10.89 | 8.48 |

| M3/h | 8.14 | 6.84 | 5.65 | 4.18 | 2.77 | 2.03 | 1.65 | 1.3 | 1.09 | 0.82 | 0.65 | 0.51 | |

| Kw | 5.43 | 9.12 | 11.3 | 11.15 | 11.08 | 10.85 | 10.99 | 10.85 | 10.94 | 10.88 | 10.89 | 10.17 | |

| 450 | L/min | 152.6 | 128.23 | 105.98 | 78.38 | 51.93 | 38.15 | 30.9 | 24.42 | 20.52 | 15.3 | 12.25 | 9.54 |

| M3/h | 9.16 | 7.69 | 6.36 | 4.7 | 3.12 | 2.29 | 1.85 | 1.46 | 1.23 | 0.92 | 0.74 | 0.57 | |

| Kw | 6.1 | 10.26 | 12.72 | 12.54 | 12.46 | 12.21 | 12.36 | 12.21 | 12.31 | 12.24 | 12.25 | 11.45 | |

woboenerkeco

woboenerkeco