CONTACT US

Product Introduction

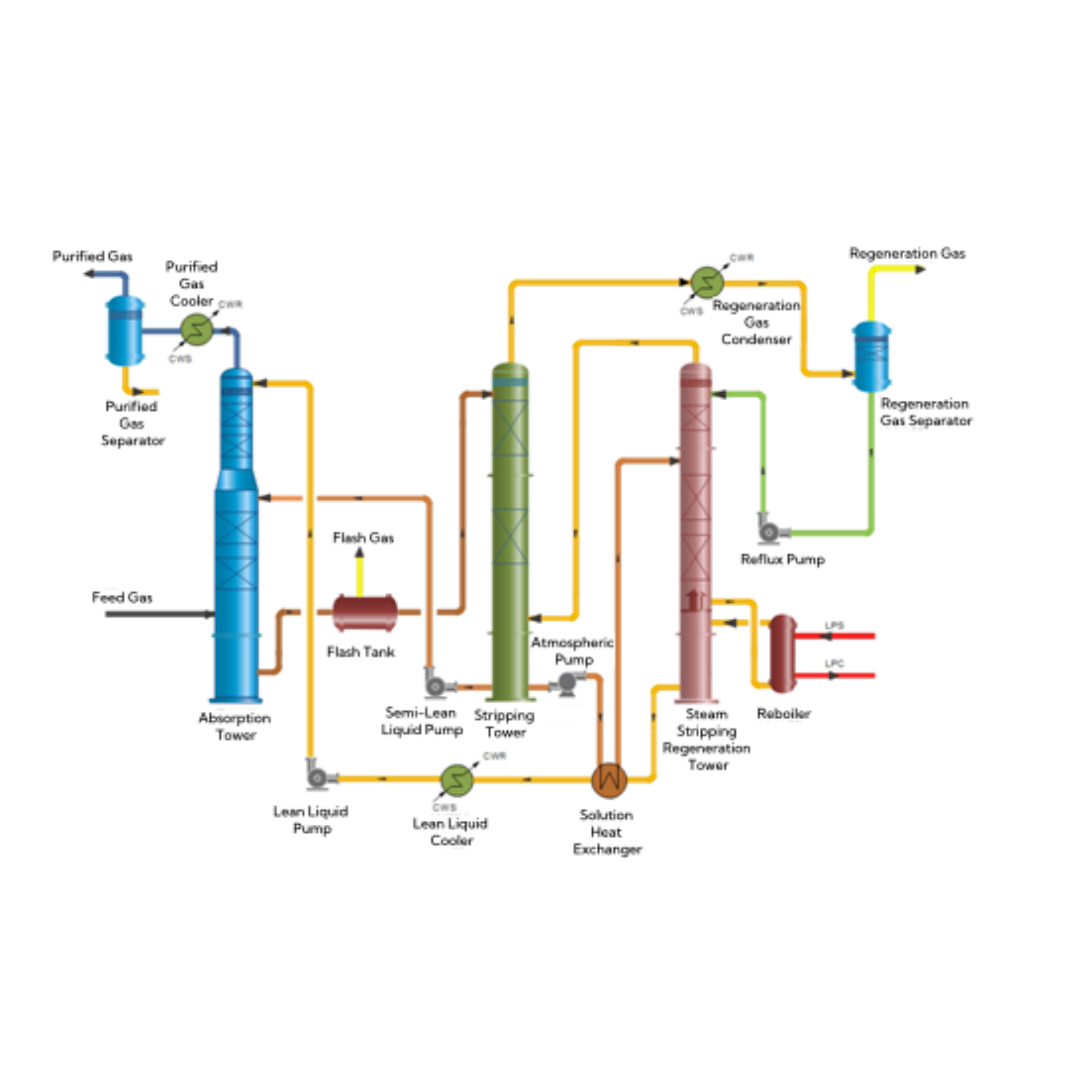

Wet decarbonization technology is a low-energy consumption decarbonization process widely used in various gas purification applications. It effectively removes carbon dioxide (CO₂) and hydrogen sulfide (H₂S) from synthesis ammonia, methanol feed gas, refinery gas, city gas, and natural gas. This technology uses methyldiethanolamine (MDEA) as the primary absorbent, combined with activators, providing both physical and chemical absorption capabilities. It ensures low thermal consumption and high purification efficiency while also removing inorganic sulfur and hydrolyzed organic sulfur.

Product Features

- Flexible Process Flow: Depending on the specific conditions of the user, the process can flexibly employ either single-stage or multi-stage absorption and regeneration combinations, reducing investment and energy consumption.

- High Decarbonization Efficiency: This process can lower the concentration of CO₂ in gases to below 20 ppm, ensuring high gas purity.

- Strong Sulfur Removal Capability: When the sulfur content is about 1 g/Nm³, it effectively reduces the total sulfur concentration to 1 ppm.

- Excellent Material Compatibility: The solvents used are basically non-corrosive to materials like carbon steel, extending the equipment's service life.

Applications

- Petrochemical Industry: Used for decarbonization treatment of chemical feed gases such as synthesis ammonia and methanol, improving product quality and reducing environmental pollution.

- Natural Gas Industry: Effectively removes CO₂ and H₂S during natural gas processing, ensuring the safety and reliability of downstream usage.

- Refinery Gas Treatment: Applying this technology in the refining process can enhance gas utilization efficiency and minimize environmental impact.

| Model | Treatment Capacity (Nm³/h) | Inlet CO₂ Concentration | Outlet CO₂ Concentration |

| APCO₂-10 | 10 | 300-1000 ppm | 1-10 ppm |

| APCO₂-50 | 50 | 300-1000 ppm | 1-10 ppm |

| APCO₂-100 | 100 | 300-1000 ppm | 1-10 ppm |

| APCO₂-200 | 200 | 300-1000 ppm | 1-10 ppm |

| APCO₂-300 | 300 | 300-1000 ppm | 1-10 ppm |

| APCO₂-500 | 500 | 300-1000 ppm | 1-10 ppm |

| APCO₂-600 | 600 | 300-1000 ppm | 1-10 ppm |

| APCO₂-800 | 800 | 300-1000 ppm | 1-10 ppm |

| APCO₂-1000 | 1000 | 300-1000 ppm | 1-10 ppm |

| APCO₂-1200 | 1200 | 300-1000 ppm | 1-10 ppm |

| APCO₂-1500 | 1500 | 300-1000 ppm | 1-10 ppm |

| APCO₂-2000 | 2000 | 300-1000 ppm | 1-10 ppm |

| APCO₂-3000 | 3000 | 300-1000 ppm | 1-10 ppm |

woboenerkeco

woboenerkeco