CONTACT US

Product Overview

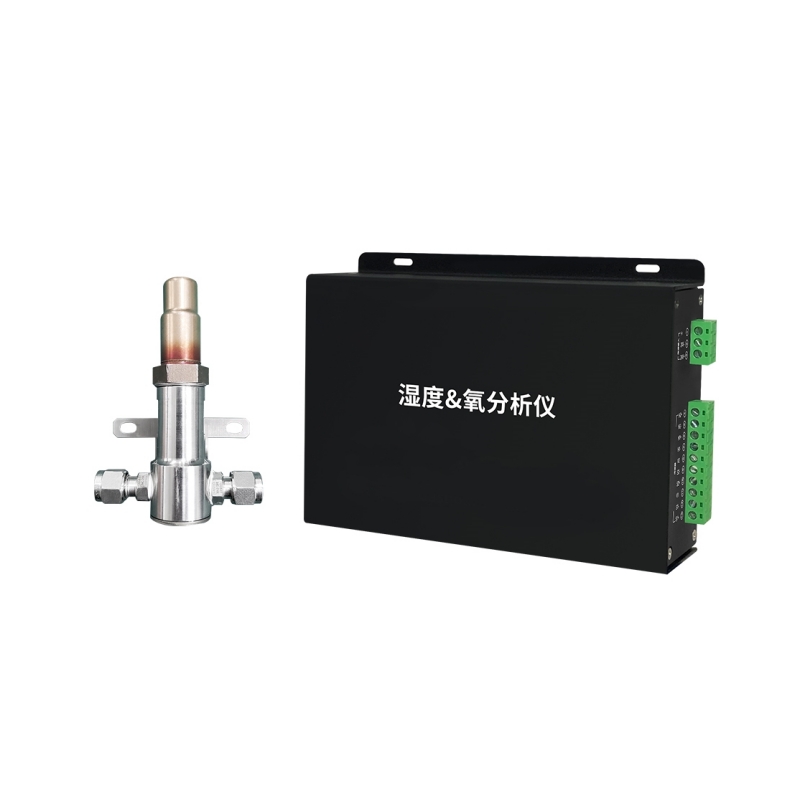

The Humidity & Oxygen Analyzer uses a ceramic zirconia principle, specifically designed for measuring oxygen content and the humidity of gas mixtures that include both oxygen and water vapor. By analyzing the relationship between the mixed gas of oxygen and water vapor and the sensor's output signal, this instrument provides accurate humidity values and oxygen concentration levels. It outputs corresponding signals for environmental humidity monitoring. With its high precision, strong stability, and long lifespan, this analyzer is capable of operating in harsh conditions, such as high temperatures and humidity. It is widely used in continuous online monitoring systems (CEMS) for desulfurization and denitrification processes in flue gas, as well as in industries such as wood, building materials, papermaking, chemicals, pharmaceuticals, fibers, textiles, tobacco, vegetables, and food processing.

Key Features

- Dual Monitoring Function: Simultaneously measures the humidity and oxygen concentration in the sample gas, providing comprehensive data.

- Heated Probe: The probe includes a heating function to prevent water vapor from condensing inside the probe, ensuring accurate measurements.

- Corrosion-Resistant Design: The probe is made from corrosion-resistant materials, making it suitable for harsh operating environments and extending the instrument's lifespan.

- Protection Features: The sensor includes a filter to prevent particulate matter and smoke dust from clogging the probe, ensuring long-term stable operation.

- Multi-Function Output: Equipped with 4-20mA analog output, RS232/RS485 communication capabilities, allowing easy integration with other devices.

- Real-Time Monitoring: Features operational indicators and fault/alarm switch outputs for real-time monitoring of the instrument's status, enhancing ease of use.

- Wide Applicability: Capable of working in various operational environments such as desulfurization and denitrification processes, wood, chemicals, and food processing industries.

Applications

- Environmental Protection Industry: Widely used in CEMS for continuous online measurement of flue gas humidity and oxygen concentration in desulfurization and denitrification processes.

- Industrial Production: Suitable for monitoring humidity and oxygen concentrations in industries such as wood, building materials, papermaking, chemicals, pharmaceuticals, fibers, and textiles.

- Food Processing: Used for humidity control in food production processes to ensure product quality.

- Tobacco and Other Industries: Used for humidity detection in industries such as tobacco and vegetables, ensuring air quality during production processes.

- Laboratories and Research: An ideal tool for precise humidity and oxygen concentration monitoring in laboratory and research projects.

| Parameter | Description |

| Measurement Principle | Ceramic Zirconia Principle |

| Measurement Range | H2O:(0~40)%VOL O2:(0.1~25)%VOL |

| Linear Error | H2O: ±2%F.S.; O2: ±2%F.S. |

| Repeatability | ±2% |

| Response Time | T90≤30S |

| Housing | Non-explosion proof structure |

| Operating Mode | Online |

| Sampling Method | Extractive/Continuous flow |

| Operating Power | 24V DC, 50W |

| Calibration Period | Recommended calibration every year |

| Ambient Temperature | (-10~+50)℃ |

| Ambient Humidity | <90%RH |

| Sample Gas Temperature | <180℃ |

| Sample Gas Pressure | Atmospheric pressure ±10% (Outlet should be atmospheric pressure) |

| Sample Gas Flow Rate | (1~5)L/min |

| Probe Interface | G 1/8 internal thread |

| Installation Mode | Instrument: Rail-mounted; Probe: Wall-mounted |

| Communication | RS485 (standard) / RS232 (optional) |

| Output Mode | 2 x 4~20mA output; 3 x relay output |

woboenerkeco

woboenerkeco