CONTACT US

Product Overview

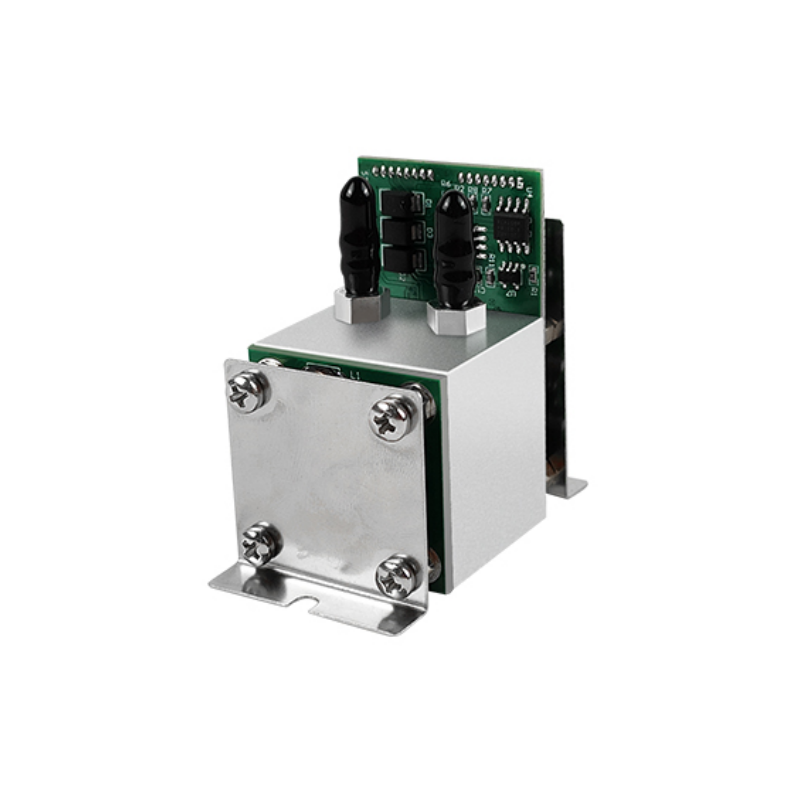

The Through-Transmission Ultrasonic Flow Meter uses ultrasonic principles to achieve high-precision gas flow velocity measurement in a non-contact manner. This device is especially suitable for real-time monitoring of flue gas emissions in harsh environments such as high temperatures, high humidity, heavy dust, and viscous impurities, offering stable operation even in complex flow fields. The product can operate independently or be integrated into a CEMS system, making it widely applicable in both municipal and industrial sectors, with strong versatility and reliability. By using ultrasonic transducers and calculating the time difference of sound propagation, it provides higher measurement accuracy compared to other methods.

Key Features

- Ultrasonic Principle Measurement: Measures the line-averaged flow velocity with an accuracy of ≤±1.5% F.S.

- Strong Anti-Interference: Utilizes autocorrelation detection technology to effectively overcome noise interference, ensuring stable monitoring in noisy environments.

- Highly Expandable: Supports 2-channel or 4-channel design, suitable for large ducts, vortex flow fields, and other complex flow environments.

- Non-Contact Measurement: The probe does not come into direct contact with the gas inside the pipe, reducing wear and maintenance of the equipment.

- Corrosion-Resistant Materials: Components in contact with gases are made of corrosion-resistant materials, suitable for measuring gas flow in acidic or moist environments.

- Wide Applicability: Supports pipe diameters of 0.3m or above, with a minimum measurable flow velocity of 0.1m/s.

- Multi-Function Measurement: Capable of simultaneously measuring gas temperature, pressure, and flow velocity, providing comprehensive data.

- High-Speed Data Processing: Equipped with a high-speed processor to ensure quick operation, with functions for calibration, configuration, query, and diagnostics.

- Rich External Interfaces: Supports output signals like 4-20mA and RS-485 for easy integration with other systems.

Applications

- Municipal Engineering: Suitable for gas flow velocity measurement in municipal facilities such as sewage treatment and waste gas treatment plants.

- Industrial Applications: Widely used in industries such as steel, power, and chemicals for flue gas flow velocity monitoring, ensuring compliance with emission regulations.

- Flue Gas Emissions Monitoring: Ideal for monitoring high-temperature, high-humidity flue gas emissions in complex environments, providing accurate flow velocity data.

- Environmental Monitoring: Applicable in environmental monitoring stations and emission monitoring centers to meet environmental regulatory requirements.

- Energy Industry: Used for flow monitoring and pipeline inspection in natural gas, coal gas, and other energy industries.

| Parameter | Description |

| Applicable Medium | Air, flue gas, and other non-combustible gases |

| Applicable Pipe Diameter | ≥0.3m |

| Number of Channels | Single-channel (customizable to 2 or 4 channels) |

| Measurement Accuracy | ≤±1.5%F.S. |

| Flue Gas Pressure Range | -10~10kPa |

| Flue Gas Temperature Range | -20~480°C |

| Flue Gas Flow Speed Range | 0~40m/s |

| Main Unit Operating Temperature | -20~60°C |

| Operating Voltage | AC 220V±10%, Frequency: 50/60Hz |

| Output Signal | 4~20mA, RS-485 |

| Protection Level | IP65 |

| Purge Fan Operating Voltage | AC 220V±10%, Frequency: 50/60Hz |

| Purge Fan Rated Power | 280W |

| Purge Fan Weight | 28kg |

woboenerkeco

woboenerkeco