CONTACT US

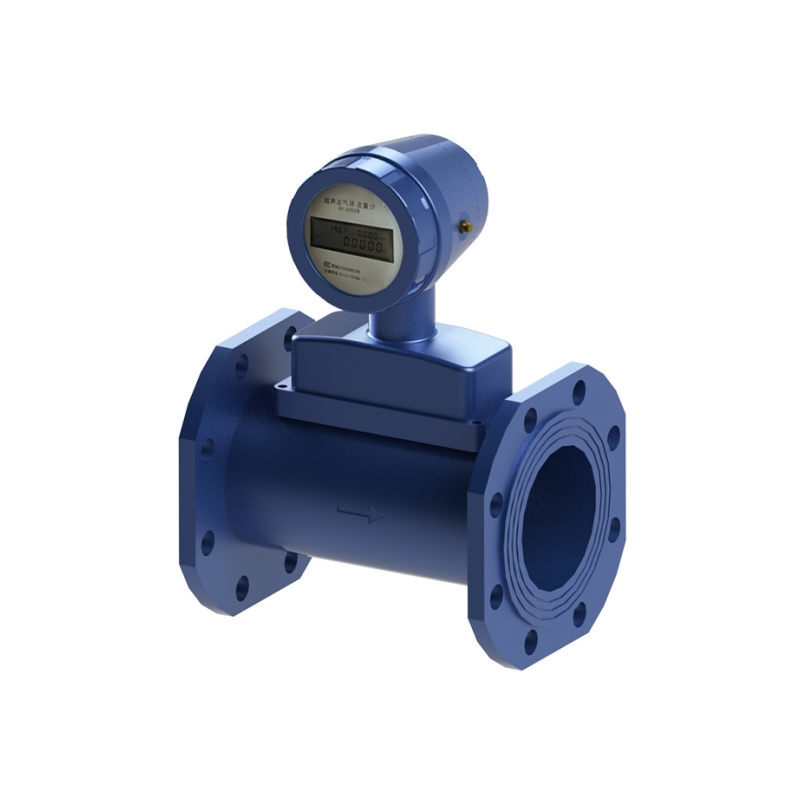

Product Overview

The Ultrasonic Gas Flow Meter uses innovative bypass-type ultrasonic gas flow measurement technology, specifically designed for measuring the flow of highly corrosive and high-humidity biogas. This technology effectively solves common issues in traditional ultrasonic measurements, such as sensor corrosion, moisture condensation, and CO₂ interference, providing more precise and stable flow metering. The bypass pipeline directs a portion of the gas for detection, enhancing signal quality and reducing interference, making it ideal for monitoring the flow of corrosive gases like biogas.

Key Features

- Enhanced Signal Quality: The bypass pipeline guides gas flow, reducing the impact of CO₂ in biogas on ultrasonic signal attenuation, improving measurement accuracy. This is especially effective in large-diameter pipelines.

- Reduced Flow Field Interference: The bypass design helps achieve a more uniform flow distribution, minimizing measurement errors caused by uneven flow fields in large pipes.

- Condensation Water Interference Elimination: The bypass pipeline effectively guides out condensation water, preventing moisture from interfering with the ultrasonic transducers, ensuring measurement accuracy.

- Stronger Corrosion Resistance: Designed to address the impact of corrosive gases such as H₂S in biogas, the bypass design minimizes direct contact between corrosive substances and the sensor or pipeline, extending the service life of the flow meter.

- Simplified Maintenance and Cost Reduction: The bypass design separates the measurement components from the main pipeline, allowing maintenance without interrupting production, reducing maintenance costs, and simplifying repairs.

Applications

- Biogas Engineering: Widely used in biogas stations and biogas projects, especially suitable for measuring the flow of high-humidity, highly corrosive biogas.

- Natural Gas Pipelines: Suitable for flow monitoring in natural gas pipelines, especially in complex environments.

- Environmental Monitoring and Energy Management: Ideal for gas resource metering and monitoring, providing accurate data support for environmental protection and energy management.

- Agricultural and Industrial Fermentation: Particularly suitable for flow measurement in fermentation processes involving high-humidity and corrosive gases.

| Parameter | Unit | DN32 | DN50 | DN80 | DN100 | DN125 | DN150 | DN200 | DN250 | DN300 |

| Nominal Diameter | - | DN32 | DN50 | DN80 | DN100 | DN125 | DN150 | DN200 | DN250 | DN300 |

| Measurement Range | m³/h | 3-65 | 8-160 | 12-240 | 20-400 | 30-600 | 40-800 | 80-1600 | 120-2400 | 160-3200 |

| Connection Type | - | Raised face flange | ||||||||

| Working Pressure | kPa | 0-200 | ||||||||

| Accuracy Class | - | 1.5 | ||||||||

| Operating Temperature | °C | -50 | ||||||||

| Ambient Humidity | % | ≤99 | ||||||||

| CH₄ Measurement | - | Range: 30-100%; Indication error: ±5% F.S. | ||||||||

| Power Supply | - | Dual battery; 5-year operation; GPRS guaranteed >2 years | ||||||||

| Communication Interface | - | RS-485 / 4-20mA / DTU | ||||||||

| Protection Level | - | IP65 | ||||||||

woboenerkeco

woboenerkeco