CONTACT US

Product Overview

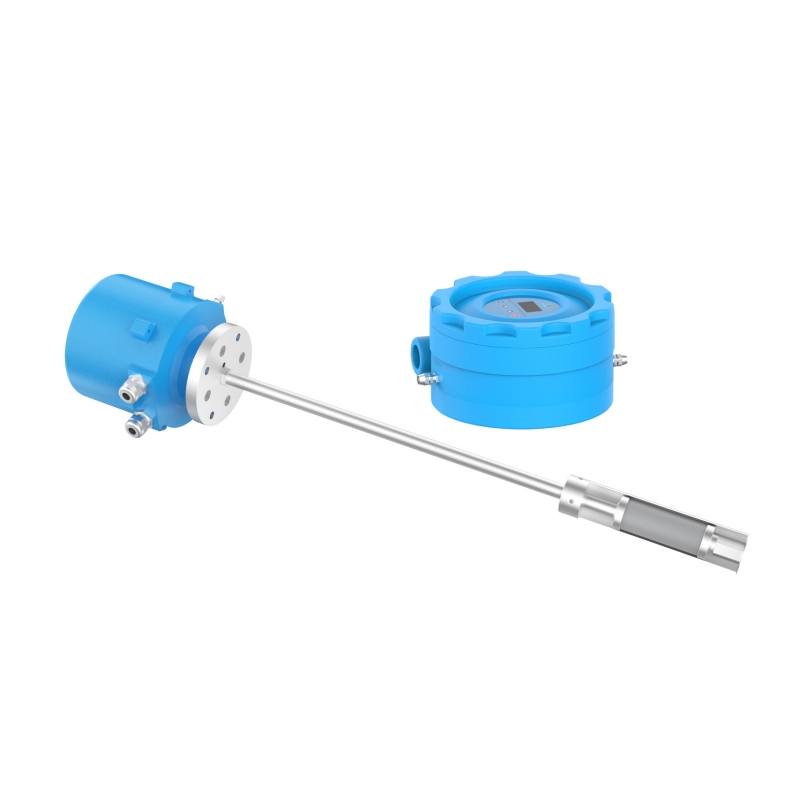

The In-Situ Zirconia Gas Analyzer is a high-temperature oxygen and combustible gas (COe) analyzer capable of simultaneously monitoring oxygen and combustible gas concentrations. This instrument helps users optimize combustion efficiency and ensure equipment operates at its best. The device operates based on the zirconia limit current and thick-film catalytic principles, using a flange installation and flow-through design for gas measurement. Its excellent performance ensures stable real-time monitoring in harsh environments such as high temperatures and dust.

Key Features

- High-Precision Measurement: Capable of simultaneously measuring oxygen and combustible gases (COe), ensuring efficient and safe combustion processes.

- Wide Temperature Range: Designed to operate in high-temperature environments, with a maximum measurable temperature of up to 1500°C.

- Temperature-Controlled Technology: The sensor incorporates a temperature-controlled design to effectively eliminate the effects of ambient temperature and inlet gas temperature variations on measurement accuracy.

- Dust Resistance: The sampling probe is equipped with a filter and baffle design, allowing stable operation in dusty environments while preventing clogging and damage.

Applications

- Combustion Control: Used in boilers, gas turbines, industrial furnaces, and other equipment to monitor the combustion process, optimize combustion efficiency, and reduce emissions.

- Steel and Metallurgy: Monitors oxygen and combustible gases in steel production processes, improving energy utilization and production efficiency.

- Power Industry: Used in power plants to monitor oxygen during combustion, ensuring stable combustion processes and reducing energy consumption.

- Petrochemical Industry: Monitors high-temperature combustion processes in the petrochemical sector to optimize gas combustion.

- Environmental Monitoring: Aids in achieving low-emission control and exhaust gas treatment, ensuring compliance with environmental standards.

| Parameter | Description |

| Component Range | O2:0~25%<br>COe:0~10000ppm |

| Response Time | O2: T90≤10s |

| COe: T90≤20s | |

| Measurement Accuracy | O2: ±1%F.S. or 0.2% |

| COe: ±5%F.S. or 25ppm | |

| Resolution | O2: 0.01% |

| COe: 1ppm | |

| Communication | RS-485/MODBUS |

| Output | 2 channels 4~20mA |

| 3 adjustable alarms | |

| Ambient Temperature | Control unit: -40°C~65°C<br>Sensor unit: -40°C~120°C |

| Protection Rating | IP66 |

| Probe Material | S316L, Alloy 600, Alumina, length customizable |

| Installation Flange | DN50 customizable |

woboenerkeco

woboenerkeco