CONTACT US

Product Overview

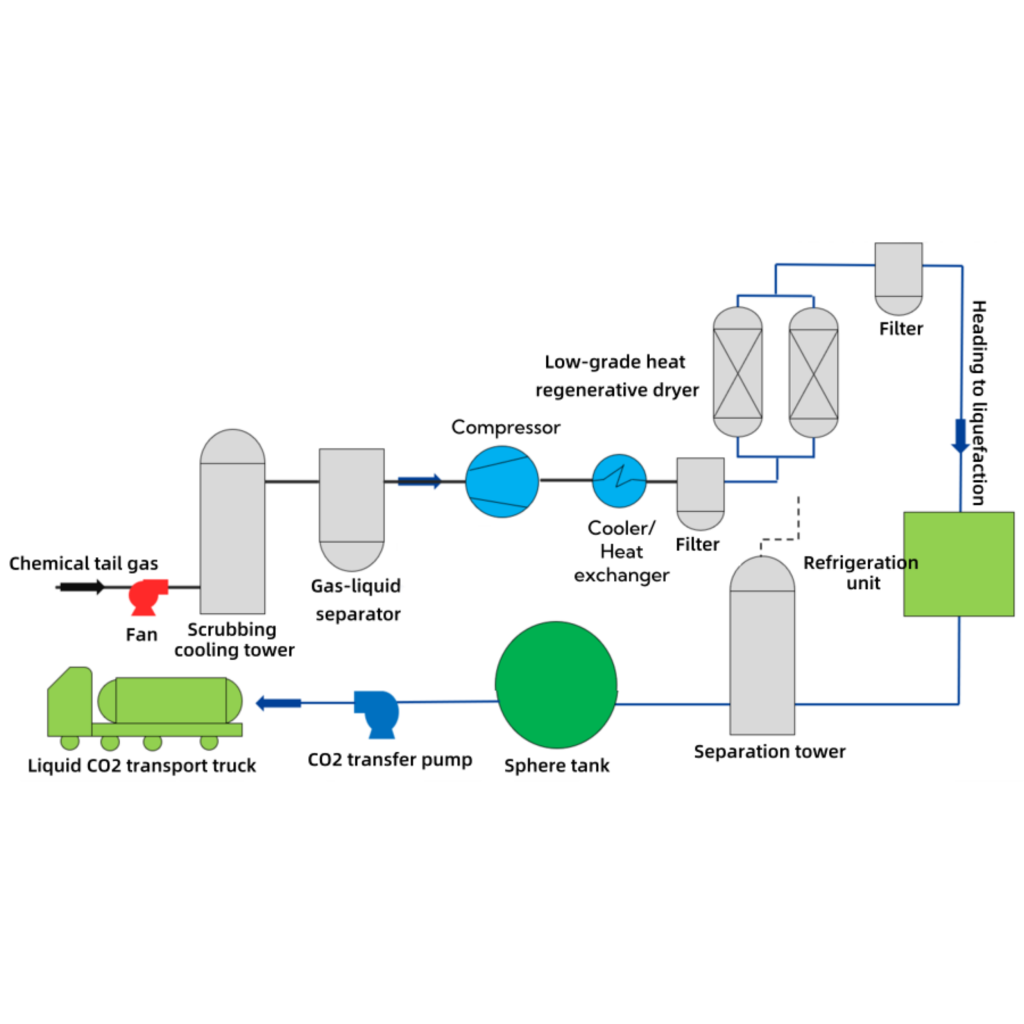

Pressure Swing Adsorption (PSA) CO₂ capture technology is an efficient method for separating and purifying carbon dioxide, primarily used to extract CO₂ from flue gases containing 40% to 80% carbon dioxide. This technology utilizes the principle of pressure swing adsorption with molecular sieves as adsorbents, processing through a series of equipment and procedures to consistently separate high-purity carbon dioxide, demonstrating extensive application prospects.

Product Features

Efficient Process:

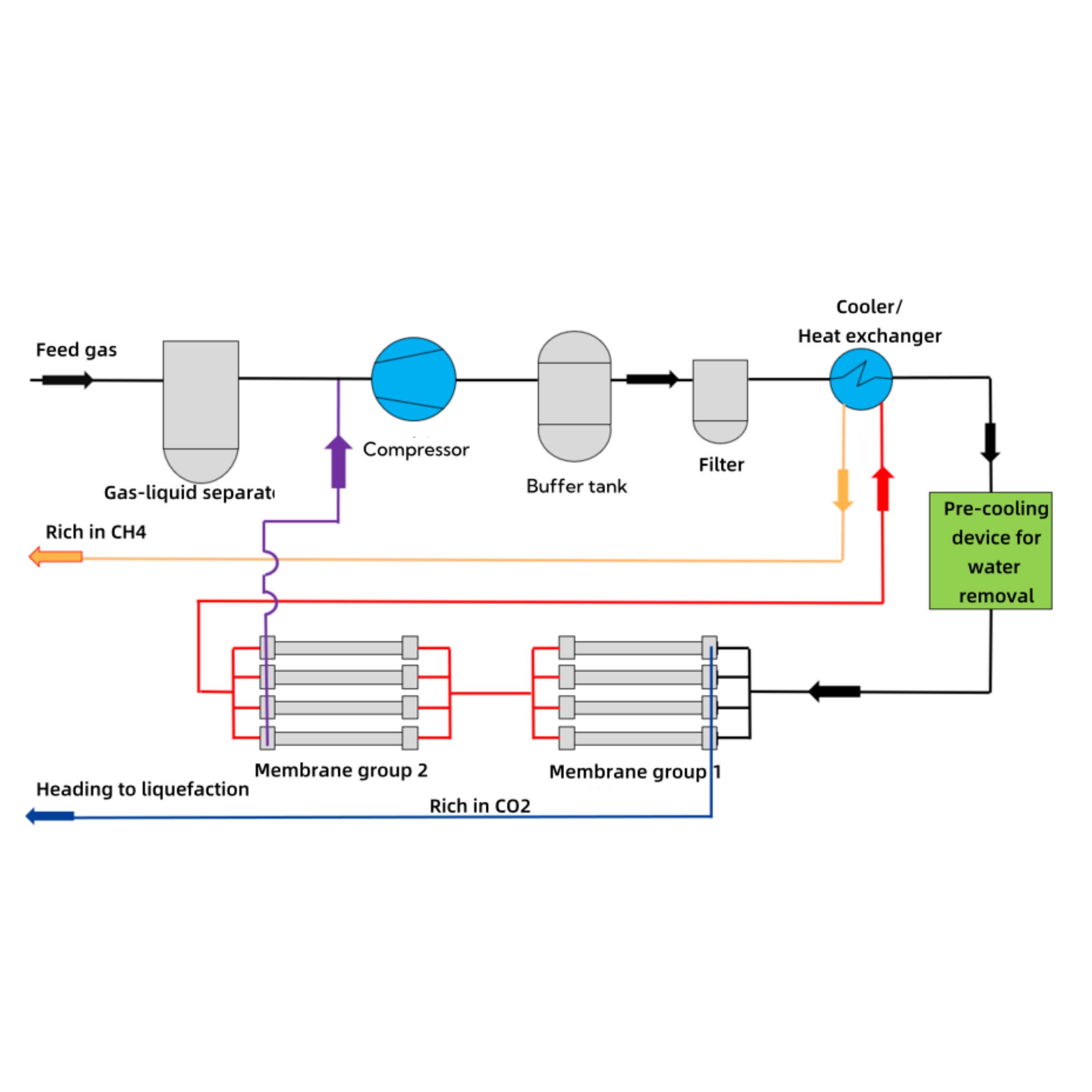

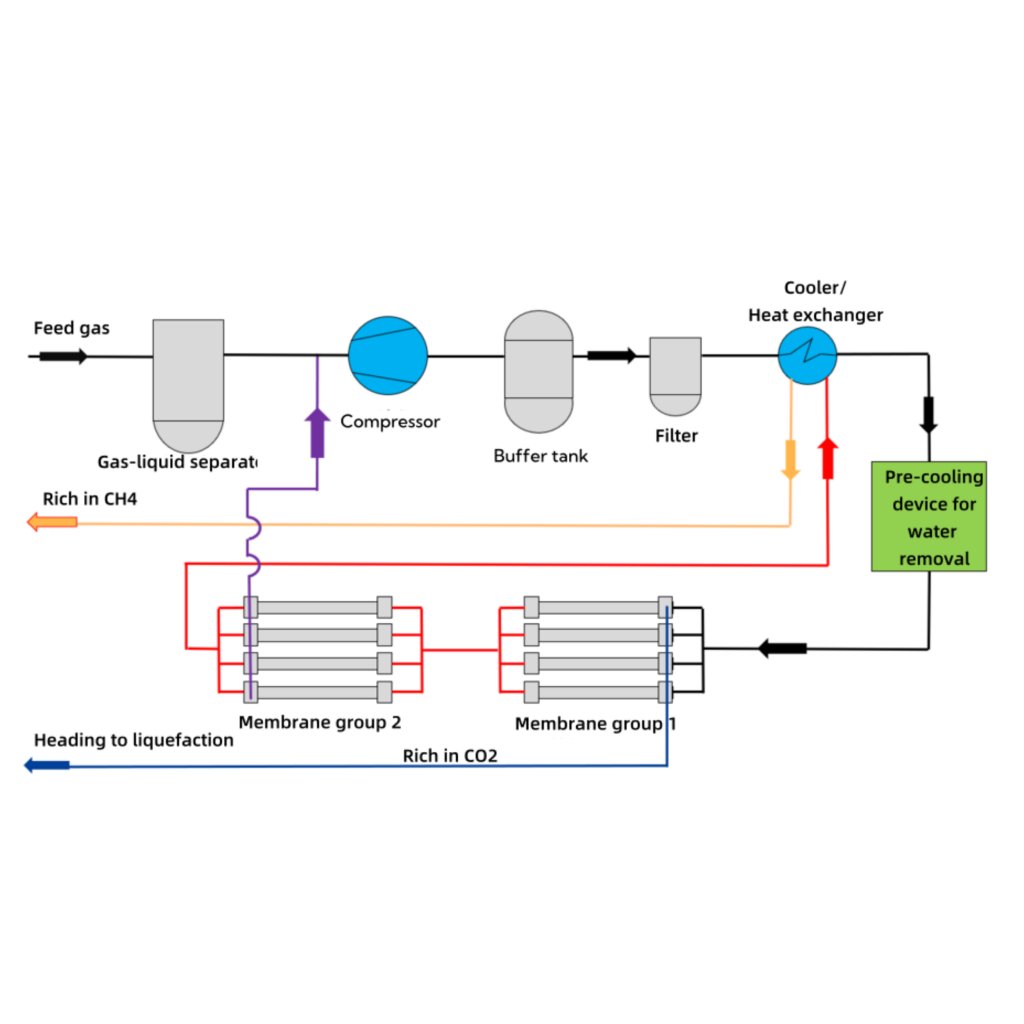

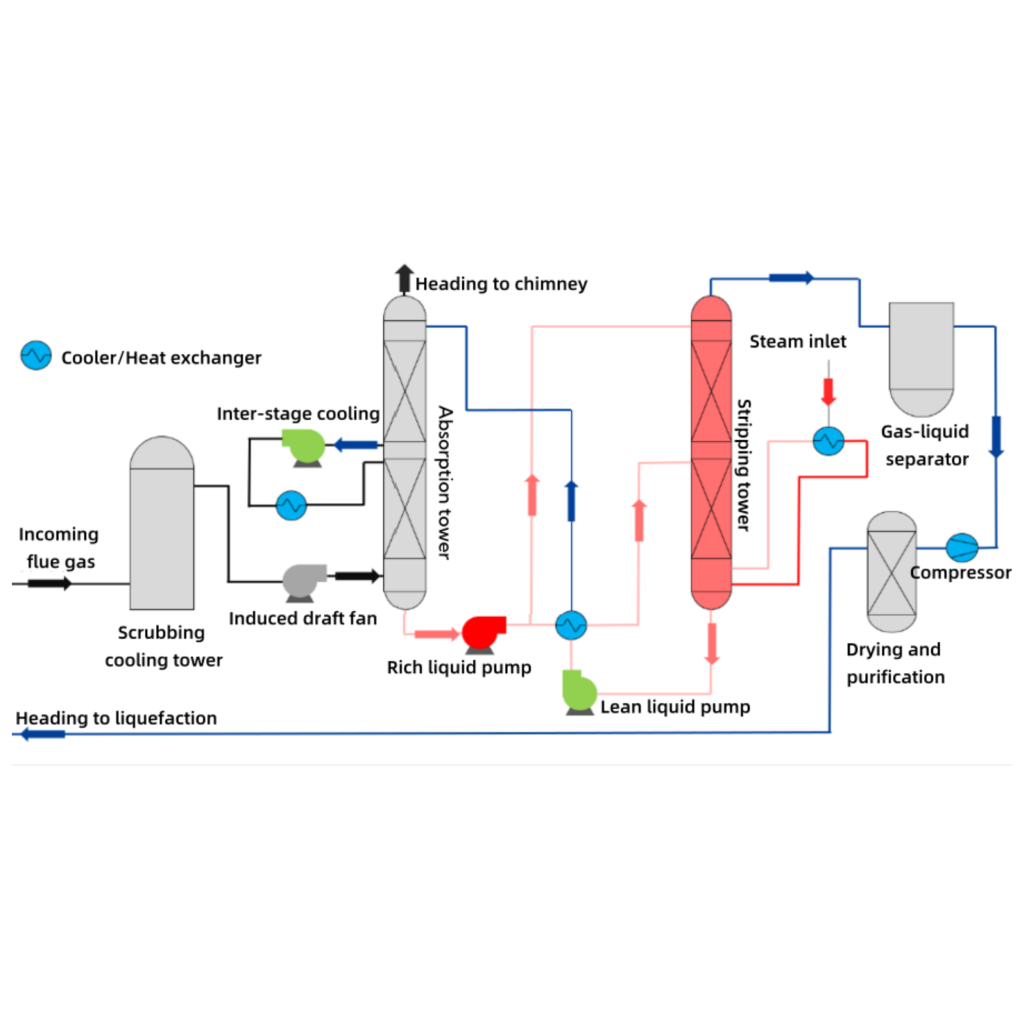

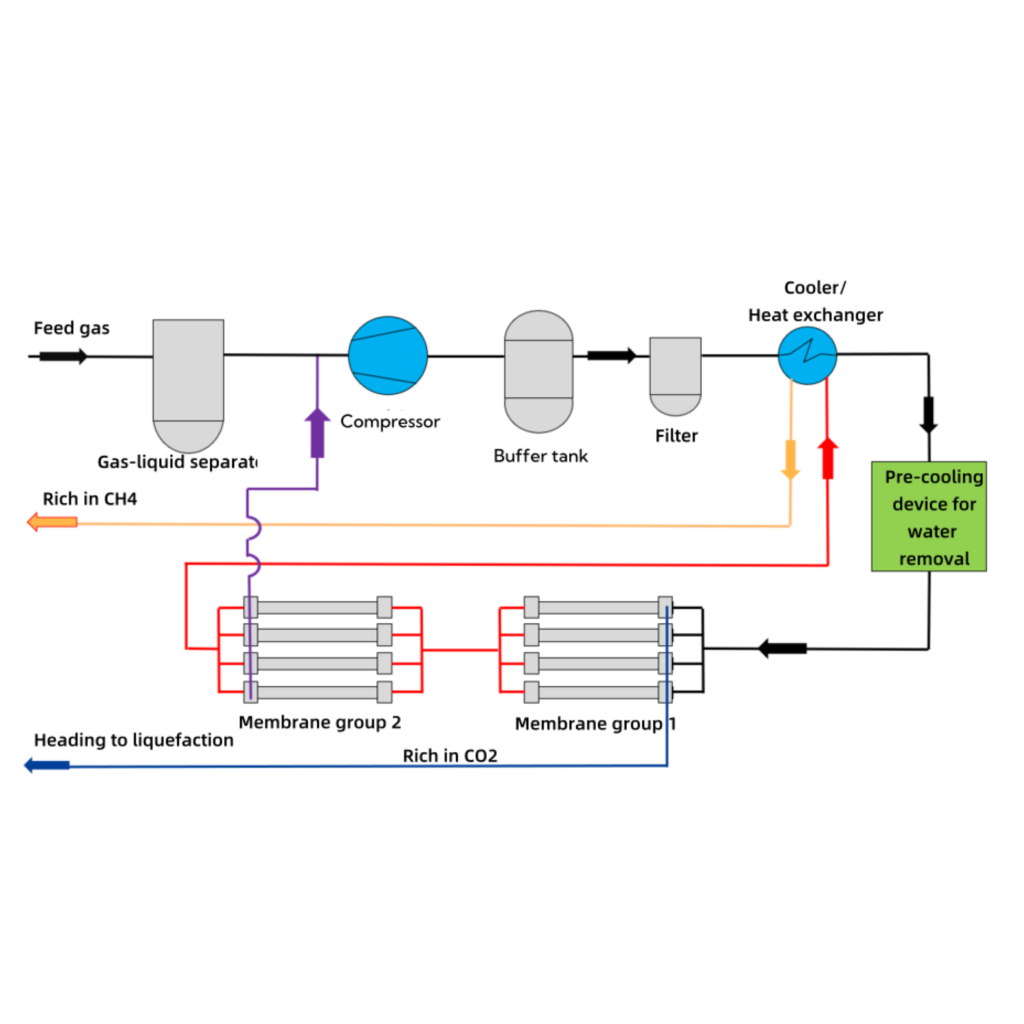

The process includes filtration, blowers, separation modules, compression, refrigeration, and storage, ensuring effective CO₂ capture and stable output.

Equipment Composition:

The system comprises key components such as a filtration system, Roots blower, PSA module, compressor (available as screw or reciprocating), refrigeration unit, separator, and storage tank, forming a complete CO₂ capture system.

Wide Applicability:

The technology can handle flue gases with CO₂ concentrations ranging from 40% to 80%, making it suitable for the separation of medium to high concentrations of carbon dioxide.

Operational Flexibility:

The system offers high operational flexibility, allowing adjustments based on different working conditions and needs to achieve efficient capture.

Stable Product Quality:

The extracted CO₂ product maintains stable quality, meeting various industrial requirements.

Advanced Adsorption Technology:

The PSA CO₂ purification unit employs molecular sieve adsorbents, ensuring efficient gas separation and purification.

Applications

Alcohol Production:

Used in distilleries to capture CO₂ released during fermentation processes, reducing emissions and enabling CO₂ recovery for reuse.

Natural Gas Decarbonization:

Applied in natural gas processing to remove carbon dioxide, enhancing the purity and value of the natural gas.

Industrial Waste Gas Treatment:

Widely utilized in other industrial sectors that produce CO₂ emissions, facilitating reduction and resource recovery.

Chemical and Pharmaceutical Industries:

In chemical and pharmaceutical manufacturing, CO₂ is captured and recovered for subsequent processes or as a raw material.

woboenerkeco

woboenerkeco