CONTACT US

Product Introduction

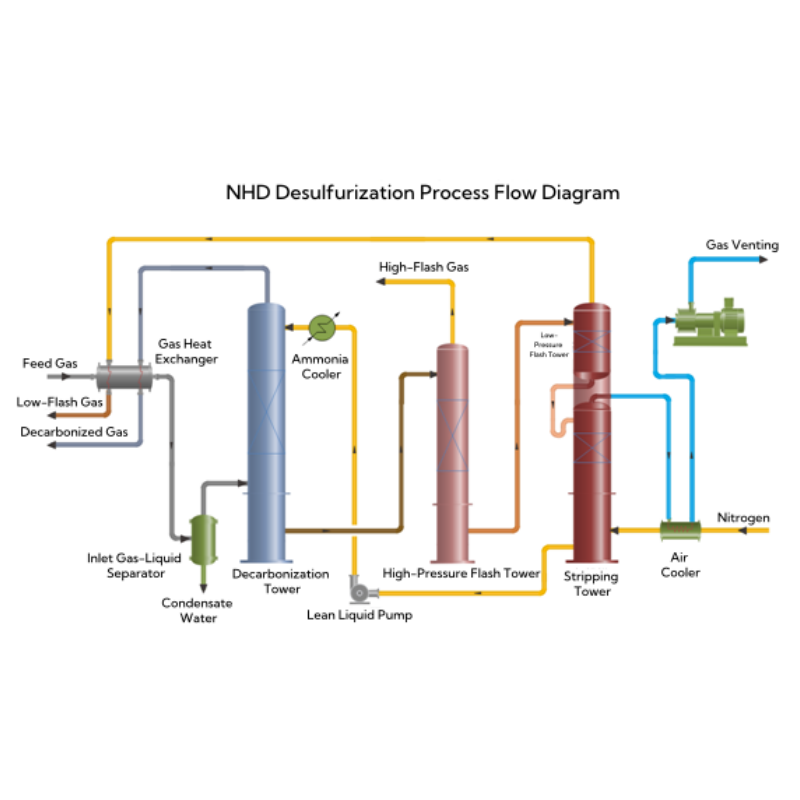

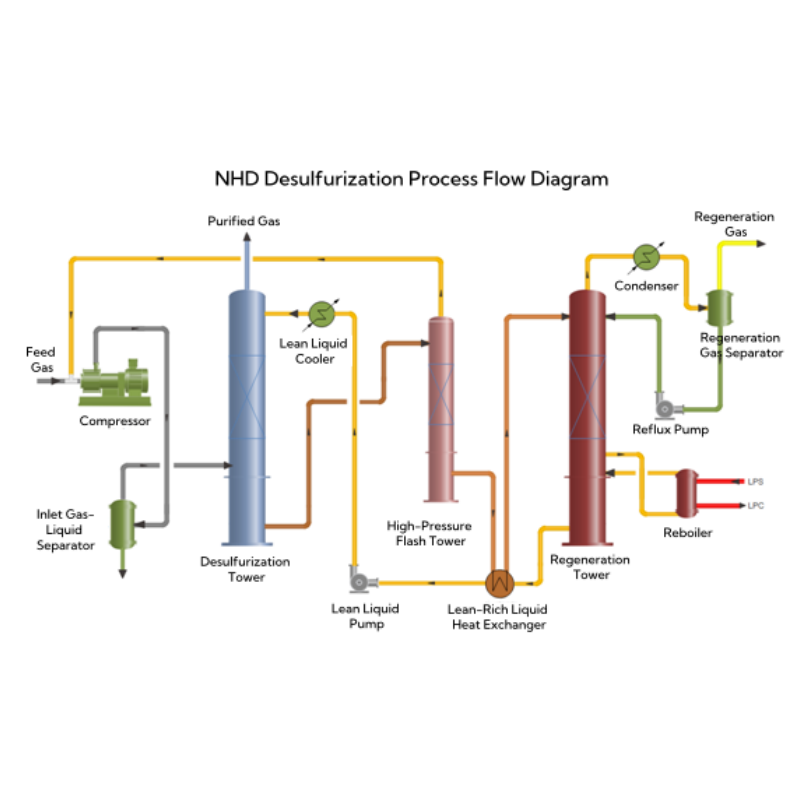

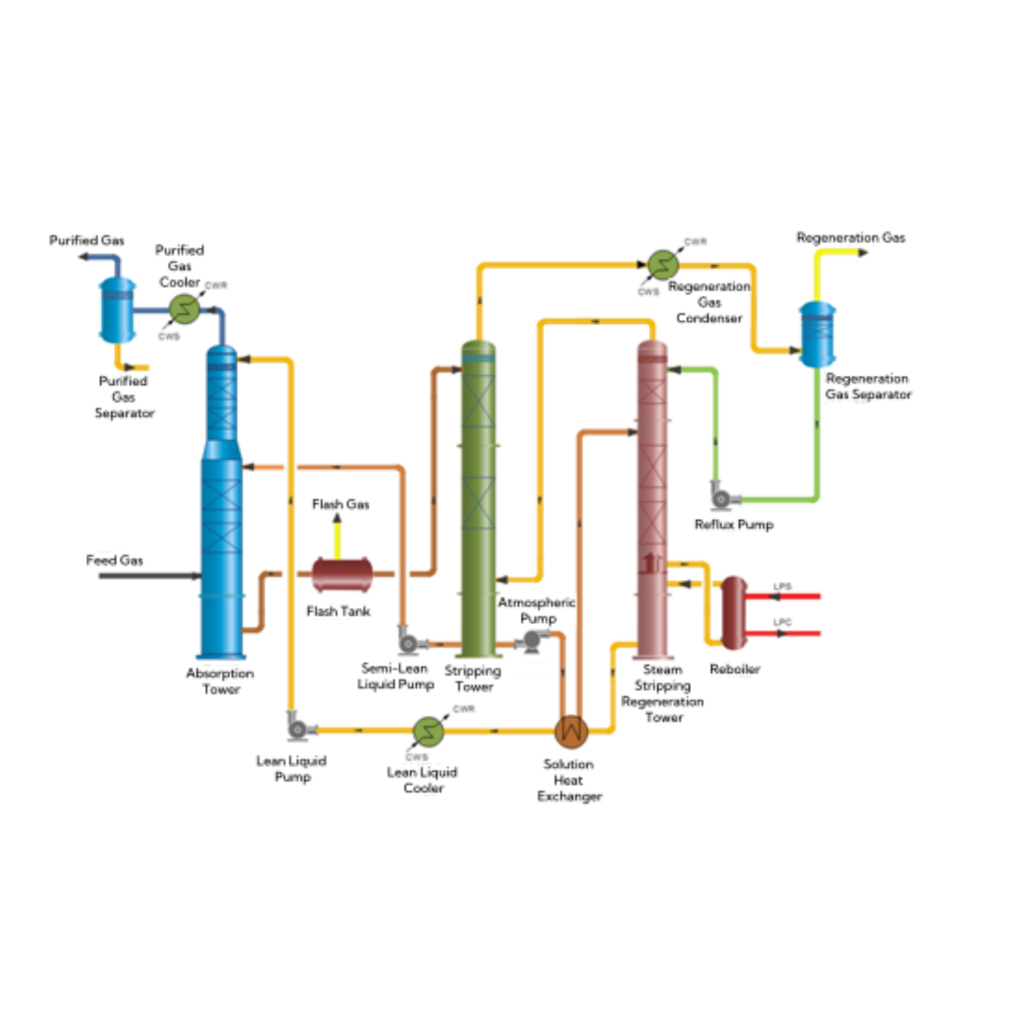

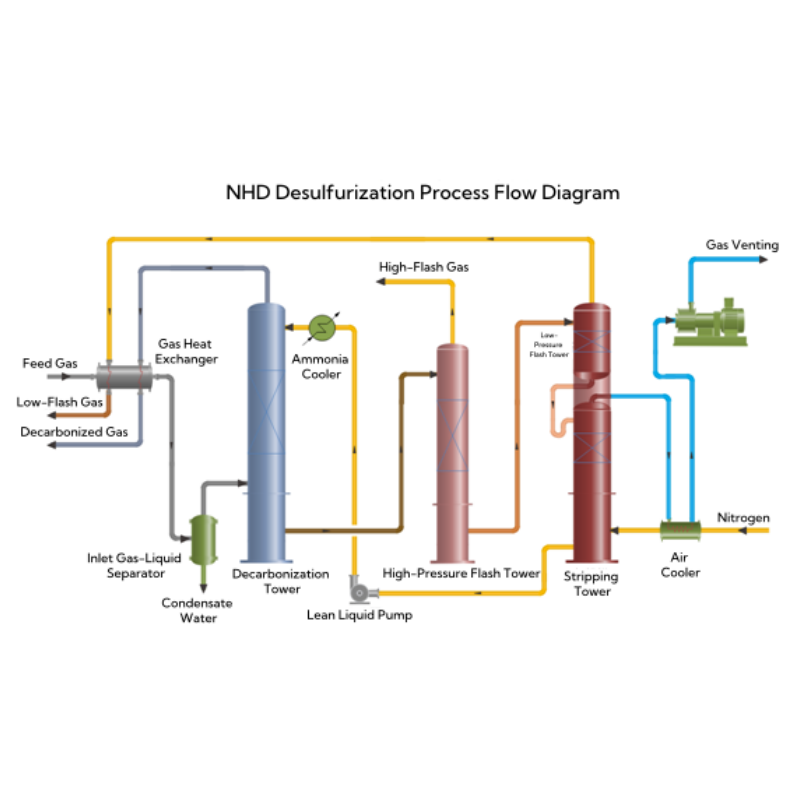

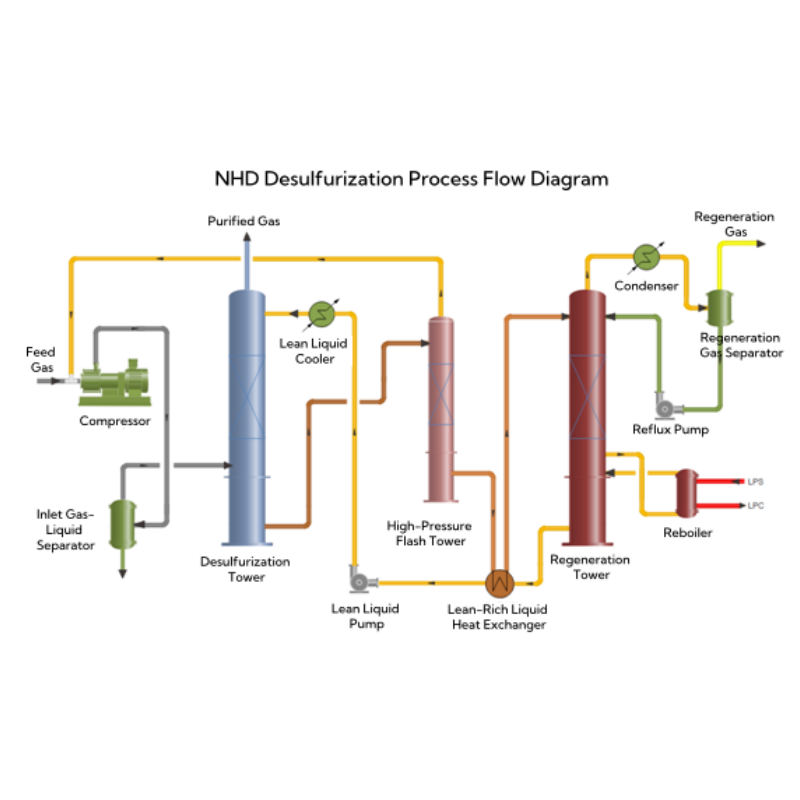

NHD desulfurization and decarbonization technology utilizes polyethylene glycol dimethyl ether as the absorbent, internationally known as Seleoxl technology. This technology has been included in the "Directory of Clean Production Technology Orientation for Key National Industries" by the National Economic and Trade Commission. It belongs to the physical decarbonization process, using air or nitrogen for regeneration, which avoids the consumption of steam and features high efficiency and environmental friendliness.

Product Features

- High Purification Efficiency: Effectively removes hydrogen sulfide and sulfur dioxide from gases, ensuring high purity of the product gas.

- Selective Absorption: The technology can selectively absorb hydrogen sulfide and carbon oxides, offering strong adaptability.

- Equipment Compatibility: The solvent used is non-corrosive, and most equipment is made of carbon steel, reducing investment costs.

- Low Volatile Loss: The solvent has a low vapor pressure, resulting in minimal volatile loss and improved operational efficiency.

- No Foam Issues: The operation does not produce foam, eliminating the need for defoamers and simplifying the process.

- Non-toxic and Odorless: The solvent is safe, non-toxic, and meets environmental protection standards.

- Low Energy Consumption: The regeneration process does not require steam consumption, reducing energy costs.

Applications

- Petrochemical Industry: Used for desulfurization and decarbonization in petroleum refining and chemical feedstocks, enhancing product quality.

- Coal Chemical Industry: Assists in purifying harmful components in syngas during coal gasification processes.

- Natural Gas Treatment: Removes harmful sulfides during natural gas purification, ensuring the safe use of natural gas.

| Connection Type | Pressure | Temperature | Flow Rate | Form |

| Flange / Threaded Pipe | Designed according to site pressure | -120℃ | Designed according to site flow rate | Vertical / Mobile / Lifting Type |

woboenerkeco

woboenerkeco