CONTACT US

Product Overview

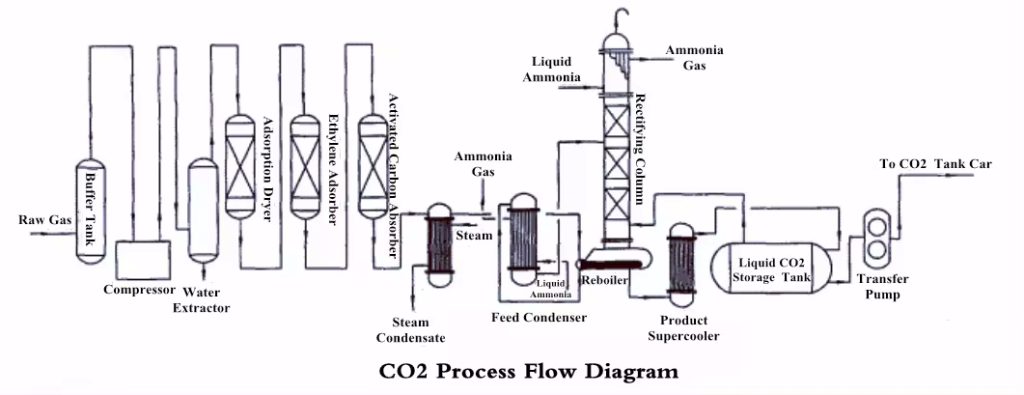

The liquid CO₂ recovery system is designed for food processing plants to capture and purify CO₂-rich off-gas from decarbonization processes, producing high-purity liquid CO₂ (≥99.9% purity) that meets national industrial-grade standards. This system is ideal for environments with high CO₂ waste concentrations, helping to enhance economic value and meet environmental regulations.

Product Features

- High Recovery Efficiency: Achieves over 75% CO₂ recovery, significantly improving resource utilization.

- High Purity: Produces liquid CO₂ with ≥99.9% purity, suitable for applications in the beverage, food, and other industries.

- Stable Operation: Features a well-designed process flow for safe, stable, and cost-effective operation.

- Environmental and Economic Benefits: Reduces CO₂ emissions effectively, providing both environmental and economic value.

Applications

- Beverage and Food Processing: Used in carbonated drinks, beer, and food preservation.

- Tobacco Industry: Supports moisture retention and gas filling in tobacco production.

- Welding and Aluminum Processing: Used as a shielding gas in welding and surface treatment for aluminum products.

- Other Industries: Applied in CO₂ recovery for nitrogen fertilizer production, hydrogen refining, and other industrial processes.

| CO₂ Purity | CO₂ ≥ 99.9% (National Standard for Industrial CO₂) |

| CO₂ Recovery Rate | ≥ 75% |

| CO₂ Parameters | ~ 2.2 MPa, ~ -20°C |

| Raw Material and Utility Consumption (per ton of Liquid CO₂) | ||||

| Item | Specification | Unit | Consumption | Remarks |

| CO₂ Raw Gas | CO₂ ≥ 85% | Nm³ | Variable | Related to CO₂ amount |

| Adsorbents, etc. | Special Use | Kg | 5 | |

| Utility Consumption (per ton of Liquid CO₂) | ||||

| Item | Specification | Unit | Quantity | Remarks |

| Electricity | 220V | kWh/h | 4 | For lighting and instrumentation |

| 380V | kWh/h | 250 | ||

| 6KV | kWh/h | 400 | Additional 400KW backup | |

| Instrument Air | P=0.6MPa, dp=-20℃ | Nm³/h | 30 | For instruments and control valves |

| Circulating Water | P=0.4MPa, <25℃ | ton/h | 50 | For one compressor |

| Steam | P=1.3MPa, ≥180℃ | ton/h | 0.15 | For steam heater |

| Liquid Ammonia | Kg/h | 2 | Consumption in ammonia circulation system | |

woboenerkeco

woboenerkeco