CONTACT US

Product Overview

The LCO2 low-temperature insulated cylinder is designed with vacuum-insulated stainless steel to store and transport low-temperature liquids such as liquid oxygen, liquid nitrogen, liquid argon, liquefied natural gas, and liquid carbon dioxide. The double-layer structure of the DPL series cylinders ensures outstanding thermal insulation performance, making them suitable for various industries including machinery, shipbuilding, healthcare, electronics, chemicals, and food, thereby meeting diverse low-temperature application needs.

Product Features

- Vacuum Insulation Design: The cylinder features a double-layer structure with a vacuum maintained between the inner and outer containers, significantly reducing heat transfer and ensuring low evaporation rates (static evaporation rate ≤ 2.1%).

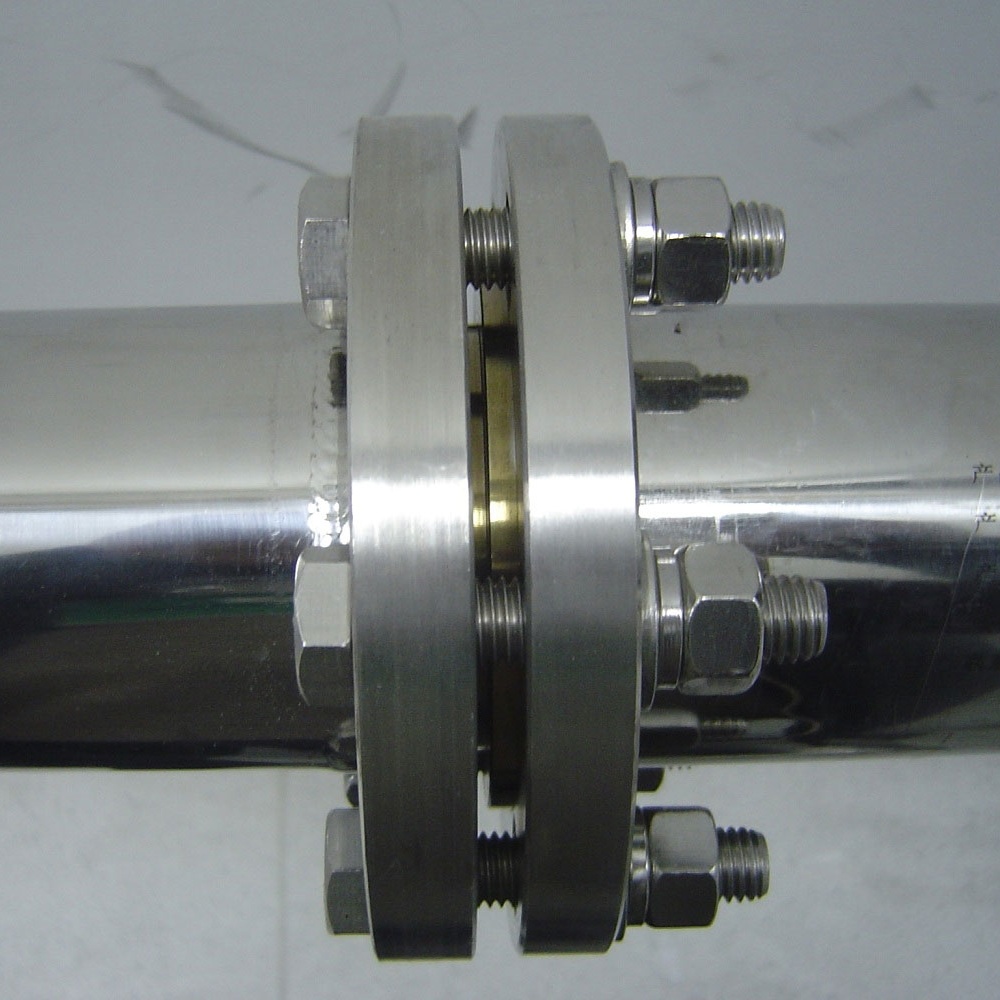

- High-Quality Materials: Both the inner and outer cylinders are made of stainless steel, with the pressurized coil using efficient copper tubing, providing excellent resistance to freeze expansion and impact, ensuring durability and safety.

- Multiple Safety Devices: Equipped with safety valves, rupture discs, pressure gauges, and liquid level indicators, ensuring the safety and stability of the cylinder during use.

- Wide Applicability: Suitable for the storage and transportation of various low-temperature liquids including liquid oxygen, liquid nitrogen, liquid argon, liquid carbon dioxide, and liquefied natural gas.

- Flexible Usage: Supports both gas and liquid extraction, easy to operate, and allows for continuous gas supply.

Applications

- Machinery and Shipbuilding: Used for the storage and transportation of low-temperature liquids, supporting various industrial operations.

- Healthcare: Widely used for the storage and transportation of medical gases, ensuring medical safety.

- Electronics Industry: Provides necessary low-temperature liquid support during electronic manufacturing and testing processes.

- Chemical and Food Industries: Suitable for the transportation of low-temperature liquids in chemical reactions and food processing.

- Scientific Research: Used for the storage of low-temperature liquids required for experiments and testing in research fields.

| Industria welded insulated cylinders(110L-240L) | ||||||||||||||

| Specifications | DPL450-V-1.37 | DPL450-V-2.05 | DPL450-V-2.88 | DPL550-240-0.12 | ||||||||||

| Geometric Volume(L) | 110 | 175 | 195 | 210 | 236 | 110 | 175 | 195 | 210 | 175 | 195 | 210 | 240 | |

| Effective Volume(L ) | 99 | 157.5 | 175.5 | 189 | 212.4 | 99 | 157.5 | 175.5 | 189 | 157.5 | 175.5 | 189 | 230 | |

| Working Pressure(MPa) | 1.37 | 2.05 | 2.88 | 0.12 | ||||||||||

| Relief valve setting(MPa) | 1.59 | 2.41 | 3.45 | 0.15 | ||||||||||

| Rupture disc setting(MPa) | 2.6 | 3.6 | 5.17 | 0.8 | ||||||||||

| Outside diameter(mm) | Φ508 | Φ610 | ||||||||||||

| Highly | 1076 | 1487 | 1613 | 1707 | 1872 | 1076 | 1487 | 1613 | 1707 | 1487 | 1613 | 1707 | 1545 | |

| Empty weight(kg) | 90 | 117 | 124 | 131 | 141 | 105 | 135 | 144 | 148 | 156 | 160 | 173 | 143 | |

| Filling Weight(kg) | LO2 | 112 | 179 | 200 | 215 | 242 | 112 | 179 | 200 | 215 | ~179 | 200 | 215 | ~~ |

| LN2 | 80 | 127 | 142 | 153 | 172 | 80 | 127 | 142 | 153 | ~127 | 142 | 153 | 186 | |

| LAr | 138 | 220 | 245 | 264 | 297 | 138 | 220 | 245 | 264 | ~220 | 245 | 264 | ~~ | |

| LNG | 42 | 67 | 74 | 80 | 90 | ~~ | ~~ | ~~ | ~~ | ~~ | ~~ | ~~ | ~~ | |

| LCO2 | 110 | ~~ | ~~ | ~~ | ~~ | 110 | 175 | 195 | 210 | 163 | 181 | 195 | ~~ | |

| NER(%Per Day)≦ | 2.74 | 2.1 | 2.02 | 1.99 | 1.96 | 2.74 | 2.1 | 2.02 | 1.99 | 2.1 | 2.02 | 1.99 | 1.96 | |

| Level gauge | Float/ Digital display

|

|||||||||||||

| Industria welded insulated cylinders(410L-1000L) | ||||||||||

| Specifications | DPL700-V-1.35 | DPL700-V-2.3 | DPL700-V-3.17 | DPL900-V-2.45 | ||||||

| Geometric Volume(L) | 410 | 455 | 500 | 455 | 500 | 455 | 500 | 800 | 1000 | |

| Effective Volume(L ) | 369 | 410 | 450 | 410 | 450 | 410 | 450 | 736 | 920 | |

| Working Pressure(MPa) | 1.35 | 2.3 | 3.17 | 2.45 | ||||||

| Relief valve setting(MPa) | 1.59 | 2.76 | 3.79 | 2.94 | ||||||

| Rupture disc setting(MPa) | 2.6 | 3.9 | 5.4 | 3.9 | ||||||

| Outside diameter(mm) | ×Phi;766 | ×Phi; 970 | ||||||||

| Size(L×W×H) mm | With wheels | With wheels | With wheels | With wheels | With wheels | With wheels | With wheels | ~~ | ~~ | |

| 1100×860 | 1100×860 | 1100×860 | 1100×860 | 1100×860 | 1100×860 | 1100×860 | ||||

| ×1865 | ×1980 | ×2095 | ×1985 | ×2095 | ×1985 | ×2095 | ||||

| No wheel | No wheel | No wheel | No wheel | No wheel | No wheel | No wheel | No wheel | No wheel | ||

| 860×860 | 860×860 | 860×860 | 860×860 | 860×860 | 860×860 | 860×860 | 1114×1089 | 1114×1089 | ||

| ×1785 | ×1900 | ×2015 | ×1900 | ×2015 | ×1900 | ×2015 | ×2079 | ×2394 | ||

| Empty weight(kg) | ~354 | ~367 | ~381 | ~427 | ~504 | ~481 | ~542 | ~905 | ~1005 | |

| Filling Weight(kg) | LO2 | ~~ | ~467 | ~513 | ~467 | ~513 | ~467 | ~513 | ~839 | ~1049 |

| LN2 | ~~ | ~332 | ~365 | ~332 | ~365 | ~332 | ~365 | ~596 | ~745 | |

| LAr | ~~ | ~573 | ~630 | ~573 | ~630 | ~573 | ~630 | ~1030 | ~1288 | |

| LNG | ~157 | ~175 | ~192 | ~~ | ~~ | ~~ | ~~ | ~~ | ~~ | |

| LCO2 | ~~ | ~~ | ~~ | ~444 | ~488 | ~413 | ~454 | 770 | 962 | |

| NER(%Per Day) | 1.8 | 1.8 | 1.7 | 1.8 | 1.7 | 1.8 | 1.7 | 1.7 | 1.7 | |

| Level gauge | Float / Digital display | |||||||||

| Industria welded insulated cylinders(Horizontal410L-499L) | ||||

| Specifications | DPL650-V-1.44 | DPL650-V-2.3 | ||

| Geometric Volume(L) | 410 | 499 | 499 | |

| Effective Volume(L ) | 369 | 449 | 449 | |

| Working Pressure(MPa) | 1.44 | 2.3 | ||

| Relief valve setting(MPa) | 1.72 | 2.76 | ||

| Rupture disc setting (MPa) | 2.6 | 3.9 | ||

| Outside diameter(mm) | Φ706 | |||

| Size(L×W×H)mm | 1777×770×1035 | 2045×770×1035 | 2045×770×1035 | |

| Empty weight(kg) | ~300 | ~335 | ~410 | |

| Filling Weight (kg) | LO2 | ~~ | ~512 | ~511 |

| LN2 | ~~ | ~364 | ~364 | |

| LAr | ~~ | ~629 | ~629 | |

| LNG | ~157 | ~191 | ~~ | |

| LCO2 | ~~ | ~~ | ~487 | |

| NER(%Per Day) | 1.8 | 1.7 | 1.7 | |

| Level Gauge | Digital display | |||

woboenerkeco

woboenerkeco