CONTACT US

Product Overview

The LCO₂ vacuum insulated pipeline (high vacuum multi-layer insulated cryogenic pipeline) is an advanced pipeline system specifically designed for transporting low-temperature liquids, such as liquid oxygen, liquid nitrogen, and liquid argon. It features a dual-pipe structure with high vacuum insulation and multi-layer insulation materials inside, effectively reducing cold loss and serving as an excellent alternative to traditional insulated pipelines, especially suitable for long-distance transportation of cryogenic media.

Product Features

- Extremely Low Heat Loss: Compared to traditional insulated pipelines, the heat leakage value of vacuum insulated pipelines is only 0.05 to 0.035 times that of conventional systems, significantly enhancing insulation performance.

- Long Service Life: The mechanical service life of vacuum pipelines can reach 10 to 15 years, while the vacuum lifespan can be sustained for 5 to 10 years, reducing maintenance costs.

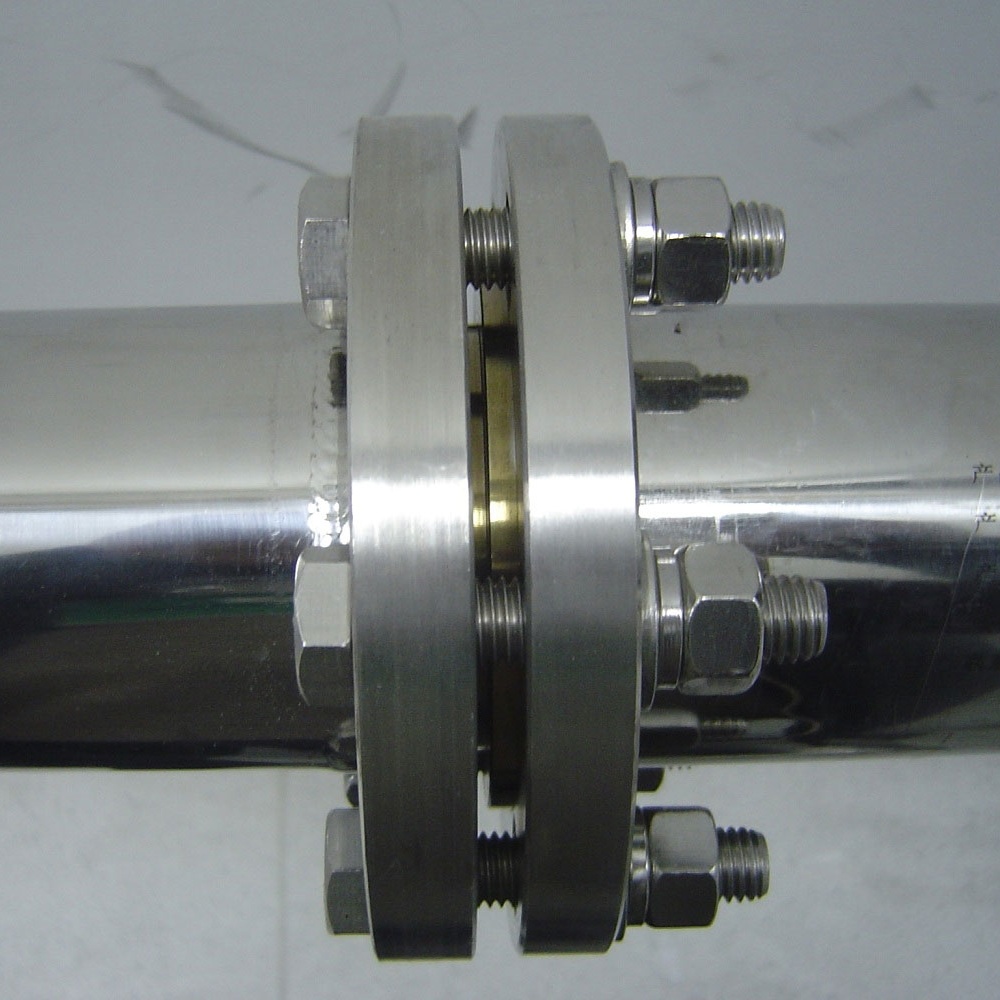

- Multiple Connection Methods: Options include vacuum slip-joint connections, vacuum flange connections, or welded connections for easy installation.

- Simple Maintenance: The optimized design allows for straightforward maintenance operations, ensuring stable system performance.

Applications

- Industrial Gas Transport: Safely transporting low-temperature liquids such as liquid oxygen, liquid nitrogen, and liquid argon.

- Chemical Industry: Providing stable supplies of cryogenic liquids in chemical production processes.

- Medical Industry: Used for the transport and storage of medical gases.

- Cold Chain Logistics: Ensuring the safe delivery of low-temperature products during cold chain transportation.

- Research Institutions: Supplying low-temperature gases for scientific experiments to support various research projects.

| Cryogenic Pipeline Specifications | |

| Parameter | Specification |

| Operating Temperature | -40 to 60 °C |

| Conveyed Media | Liquid Oxygen, Liquid Nitrogen, Liquid Argon |

| Design Temperature | -196 to 60 °C |

| Nominal Diameter | See vacuum pipe specification table |

| Pipeline Design Pressure | 1.6 MPa |

| Compensator Selected Pressure Level | 4.0 MPa |

| Insulation Method | High vacuum multi-layer winding insulation |

| Connection Method | Vacuum flange connection |

| Vacuum Leak Rate | ≤ 1.0 × 10⁻¹⁰ Pa·m³/S |

| Vacuum Venting Rate | ≤ 1.0 × 10⁻⁸ Pa·m³/S |

| Liquid Nitrogen Interlayer Vacuum Degree | ≤ 5.0 × 10⁻³ Pa |

| Vacuum Pipeline Cold Loss | 0.52 W/m |

| Material | 06Cr19Ni10 |

woboenerkeco

woboenerkeco