CONTACT US

Product Overview

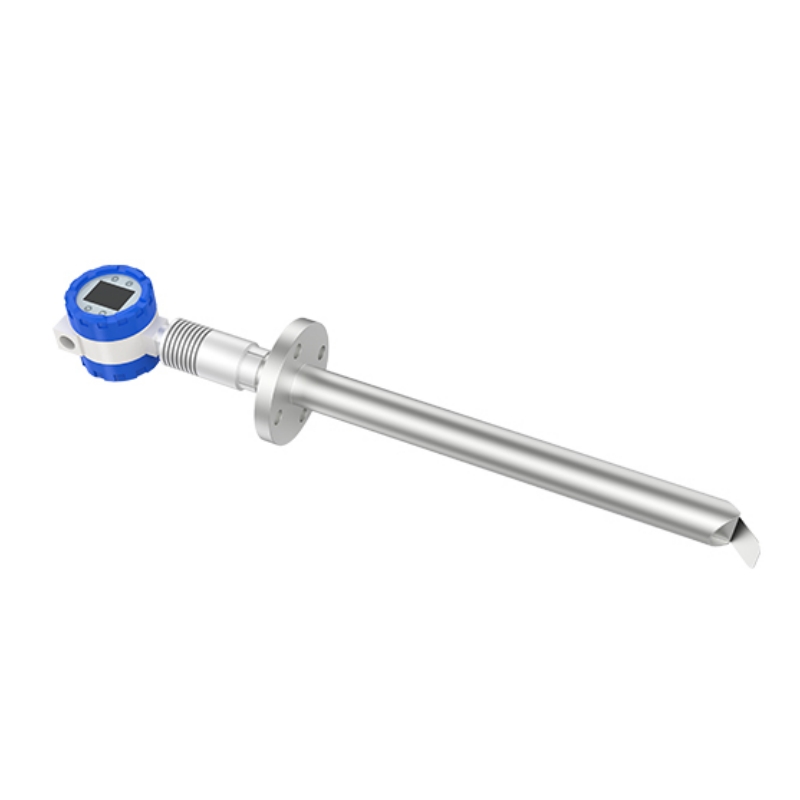

The Insert-type Oxygen Analyzer is designed for real-time oxygen concentration detection in industrial combustion processes. It uses a high-precision zirconia sensor and an integrated insert sampling design to quickly and accurately monitor the oxygen content in the flue gases generated by combustion equipment. This tool helps operators monitor combustion levels in real-time, optimize combustion control, and improve energy efficiency. It is widely used in industries such as petrochemical, power, chemicals, and steel, helping reduce energy consumption and achieve energy-saving and emission reduction goals.

Key Features

- High-Precision Zirconia Sensor: Features fast response and long service life, ensuring accurate and stable measurement results.

- Innovative Sampling Probe Design: Uses a flow-guided sampling design, automatically drawing in the sample gas and simplifying the operation process.

- High-Temperature Tolerance: Can operate continuously in high-temperature environments up to 700°C, making it suitable for harsh industrial conditions.

- IP65 Protection Rating: Offers dust and water resistance, allowing the device to function reliably in various environments, unaffected by adverse weather conditions.

- Precise Calibration: Oxygen concentration can be calibrated on-site with air or standard gases to ensure measurement accuracy.

- Full Alarm Functionality: The instrument triggers contact alarms when oxygen concentrations exceed preset limits.

- High-Temperature Protection: Features an internal temperature alarm to safeguard the instrument when excessive temperatures are detected.

- Signal Transmission Options: Supports both RS485 and 4-20mA signal transmission methods, making it compatible with a wide range of field conditions.

Applications

- Petrochemical Industry: Used for oxygen concentration monitoring in boilers, combustion furnaces, and other equipment to optimize combustion efficiency.

- Power Industry: Provides real-time oxygen concentration monitoring in power plant combustion equipment, reducing energy waste and improving production efficiency.

- Steel and Metallurgy: Monitors oxygen content in flue gases during high-temperature smelting processes, helping adjust combustion conditions.

- Chemical Industry: Ensures stable and safe oxygen levels in reaction furnaces, heating furnaces, and other chemical production processes.

- Textile and Building Materials Industries: Monitors oxygen concentrations to ensure safe and energy-efficient combustion processes.

| Parameter | Description |

| Sampling Method | Divergence type |

| On-site Installation | Flange connection (DN40) |

| Gas Path Interface | Calibration interface (6mm) |

| Pipe Diameter | Outer diameter 50mm |

| Waterproof Rating | IP65 |

| Sample Probe Length | 500/1000/1500mm (customizable) |

| Applicable Flue Gas Temperature | 0-700℃ |

| Screen | LCD Color screen (128*160) |

| Measurement Range | Range 0-25%, Resolution 0.1% |

| Measurement Accuracy | ±2%F.S. |

| Repeatability | ≤±1% |

| Stability | ±2%F.S./7D |

| Response Time | T90<15s |

| Relay Output | 2 groups |

| Signal Output | RS-485 and (4-20)mA |

| Power Supply | DC24V±10%/2A |

woboenerkeco

woboenerkeco