CONTACT US

Product Overview

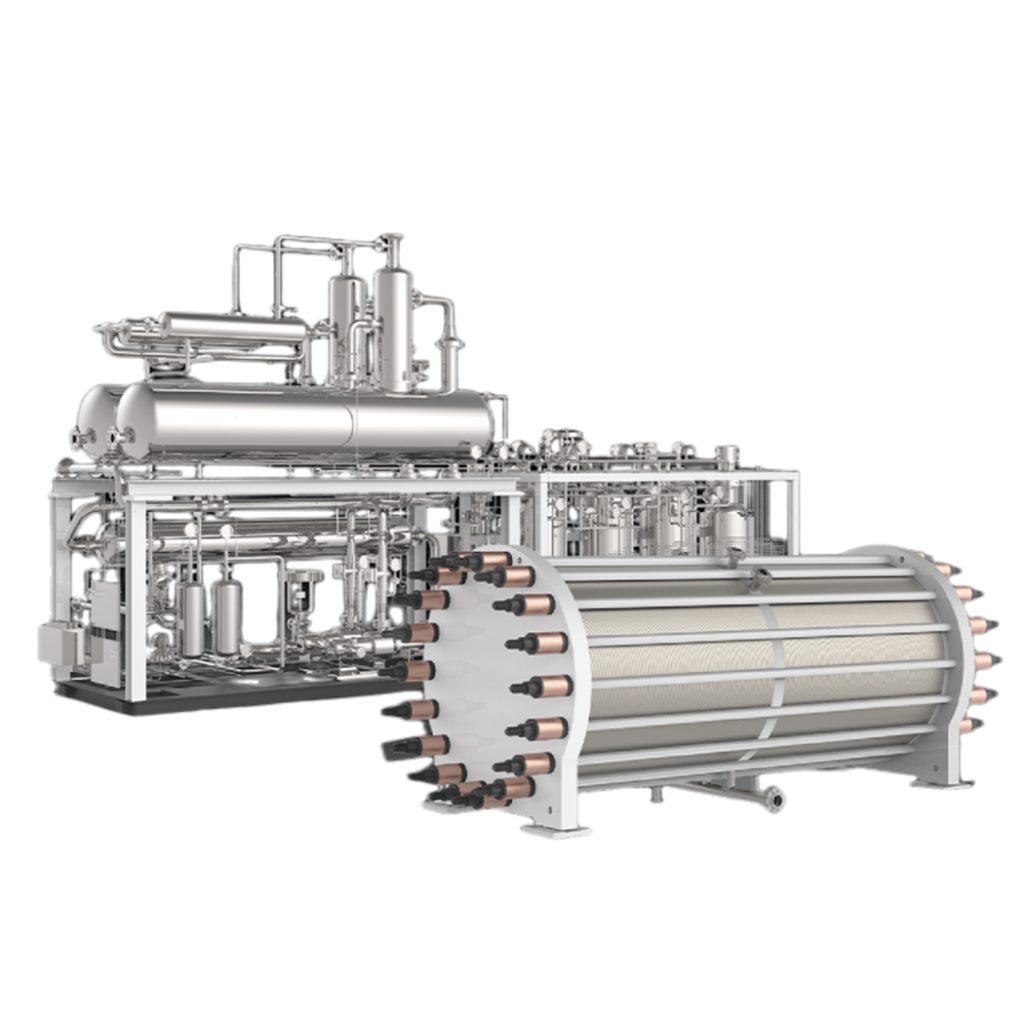

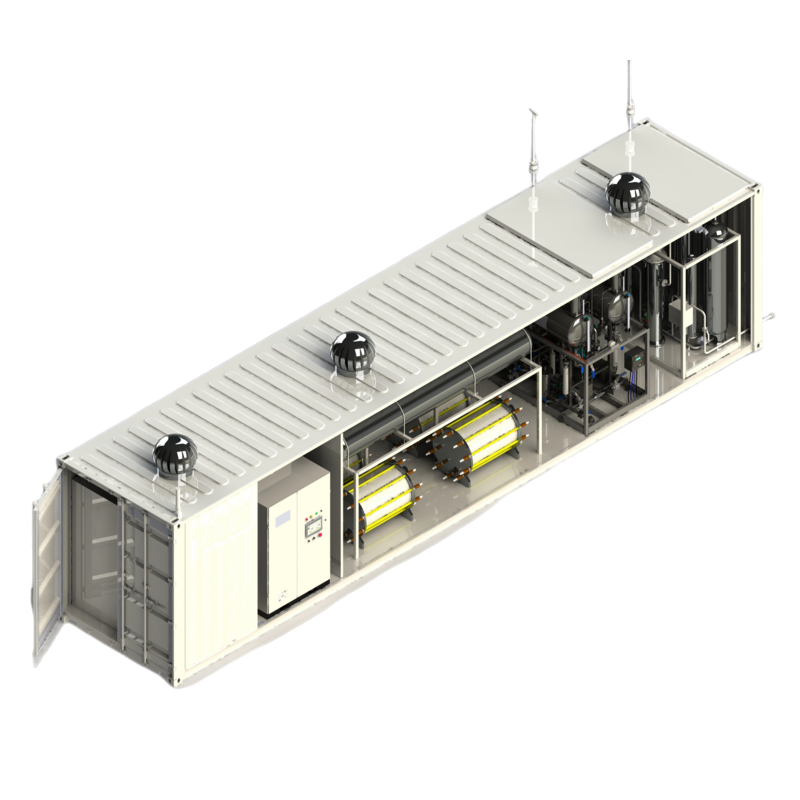

The Hydrogen Production and Refueling Integrated Station combines hydrogen production, compression, storage, and refueling into one system. Utilizing existing natural gas pipelines, CNG, and LNG refueling stations, the station uses efficient technologies such as Steam Methane Reforming (SMR), medium-temperature shift, and Pressure Swing Adsorption (PSA) to produce high-purity hydrogen. This integrated station not only reduces hydrogen transportation costs but also minimizes storage and transportation expenses. Additionally, optimized refueling equipment brings the hydrogen fuel cost for hydrogen fuel cell vehicles closer to that of gasoline and diesel vehicles, providing strong support for environmental protection and the future energy transition.

Technical Features

- Integrated Design: Hydrogen production, compression, storage, and refueling functions are integrated, reducing transportation costs and improving overall efficiency.

- High-Purity Hydrogen Production: The system utilizes SMR and PSA technologies to ensure the hydrogen produced meets high purity standards, suitable for various applications.

- Efficient Compression and Storage: The use of high-pressure hydrogen storage bottles ensures safety, reliability, and optimal utilization of storage capacity, supporting high-pressure multi-stage refueling.

- Flexible Operation: The hydrogen production unit offers great operational flexibility and can run without the need for large hydrogen storage tanks, minimizing downtime.

- Automated Control: With high automation, the system significantly reduces manual operation, improving safety and operational efficiency.

- Strong Adaptability: The system can be easily expanded or modified from existing natural gas refueling stations, facilitating rapid deployment and application.

Application Areas

- Hydrogen Fuel Cell Vehicle Refueling Stations: Provides efficient hydrogen refueling services for hydrogen fuel cell vehicles.

- Energy Supply: Offers stable and reliable hydrogen supply for industrial, transportation, and research sectors.

- Natural Gas Pipeline Expansion: Utilizes existing natural gas infrastructure to build hydrogen refueling stations, reducing initial investment and improving facility efficiency.

- Environmental and Green Energy Fields: Supports the low-carbon economy and environmental goals, promoting the use of clean energy solutions.

woboenerkeco

woboenerkeco