CONTACT US

Product Overview

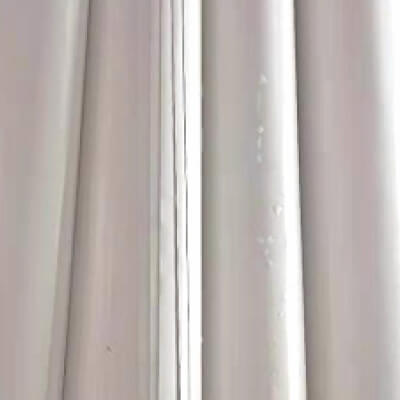

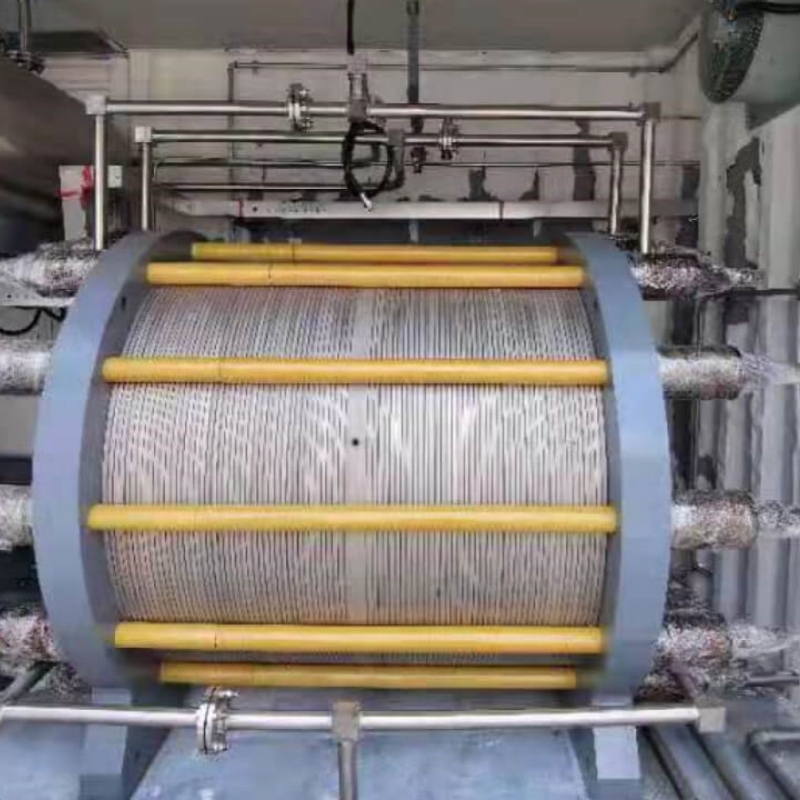

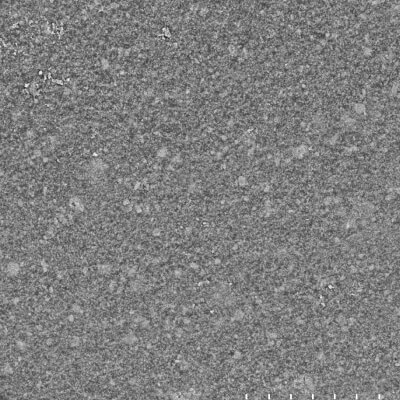

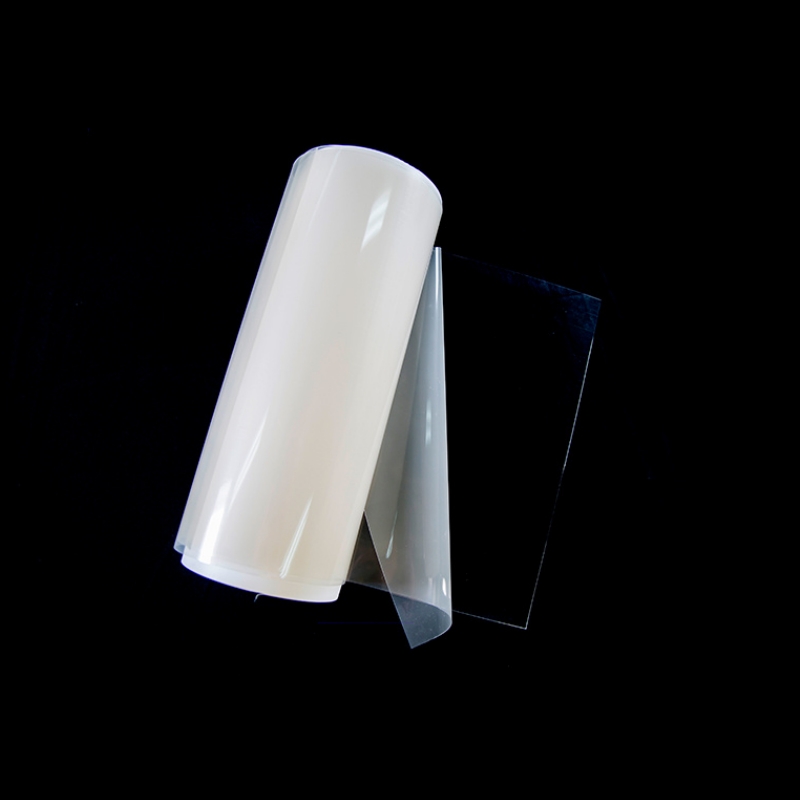

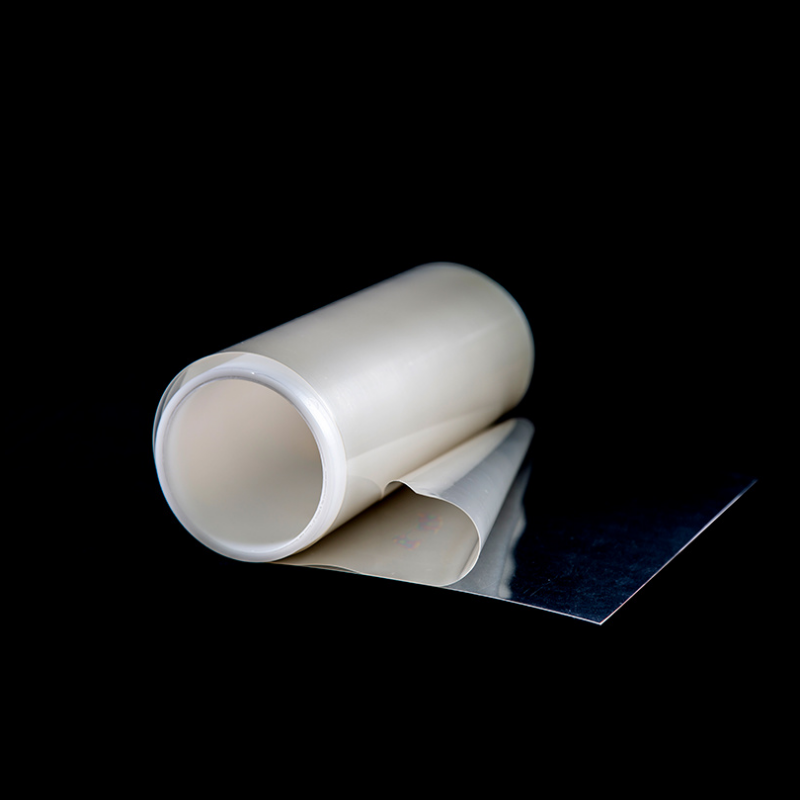

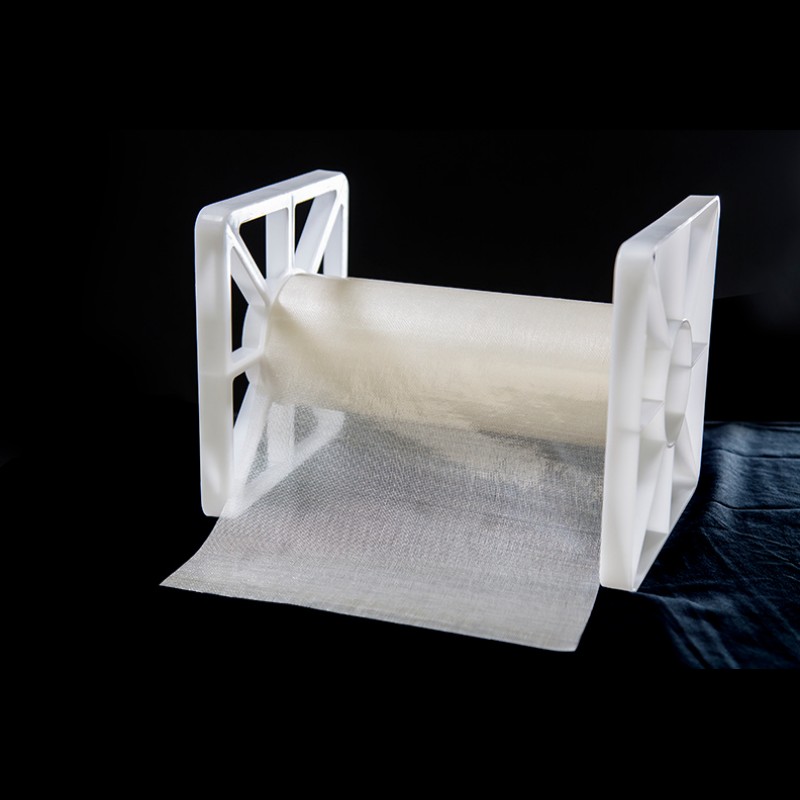

The electrolytic hydrogen production membrane is a crucial component in the water electrolysis process for hydrogen production. Serving as a separator in electrolysis cells, this membrane enables efficient ion transmission while effectively isolating hydrogen and oxygen to prevent gas cross-mixing. This enhances electrolysis efficiency and prolongs the equipment's lifespan. Carbon Energy Technology’s new composite membrane material is specially designed for "alkaline water electrolysis hydrogen production" with a composite structure of organic polymers, ceramic powder, and an internal support layer, optimized for high-efficiency gas separation.

Product Features

Permanent Hydrophilicity: Strong electrolyte wettability ensures stable performance over time.

High Purity: Delivers high gas purity with hydrogen purity reaching 99.9%.

Safety and Stability: High bubble point pressure design ensures operational safety.

Low Ionic Resistance: Surface resistance as low as ≤0.3 Ω·cm² (at 30°C, 30wt.% KOH), enhancing electrolysis efficiency.

Customizable Dimensions: Effective membrane width up to 2.5 meters, customizable to specific customer requirements.

Long Service Life: Exceptional chemical and mechanical stability with a lifespan of over 7 years.

Applications

Alkaline Water Electrolysis for Hydrogen Production: Provides efficient, stable membrane material support for green hydrogen production, widely used in the clean energy sector.

| Model | EHPM-500 | EHPM-200 |

| Thickness (μm) | 500±50 | 200±30 |

| Pore Point (bar) | 5.0±1 | 3.5±1 |

| Porosity (%) | 60±10 | 60±10 |

| Surface Resistance (Ω·cm²) | ≤0.3 (30°C, 30wt.% KOH) | ≤0.2 (30°C, 30wt.% KOH) |

| Tensile Strength (MPa) | ≥20 | 16-19 |

| Volume Expansion (%) | <1.5 | <1.5 |

| Operating Temperature (°C) | ≤110 | ≤110 |

| Lifetime (years) | ≥7 | ≥7 |

woboenerkeco

woboenerkeco