CONTACT US

Product Overview:

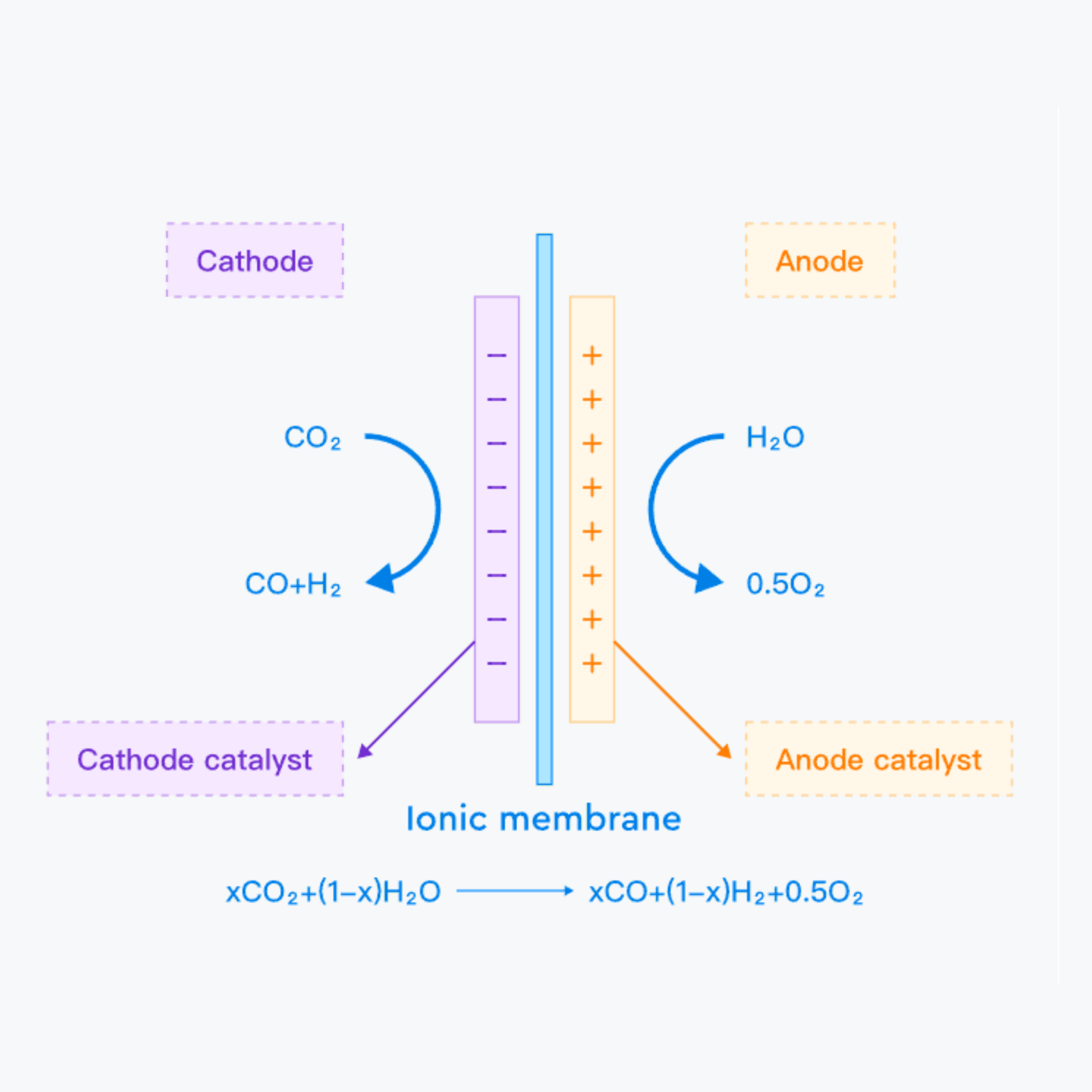

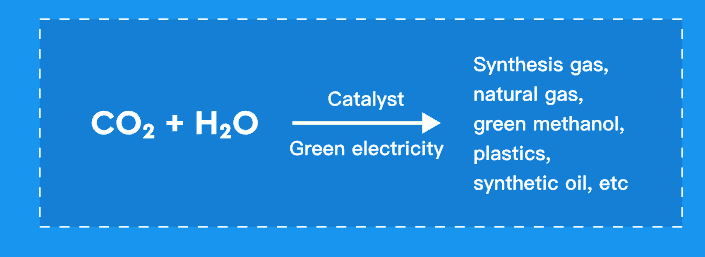

Electrolytic CO₂ to syngas conversion is an innovative electrochemical reaction technology that utilizes CO₂ and water from the electrolyte to transform these raw materials into syngas (CO and H₂) under the influence of electrical energy. The process involves electron reception through a cathode catalyst, while oxygen is released at the anode catalyst, ensuring that the product gases do not mix. This technology provides a sustainable and low-energy solution for syngas production, effectively utilizing atmospheric CO₂ and reducing reliance on traditional fossil fuels.

Key Features:

- High-Efficiency Conversion: Achieves efficient conversion of CO₂ and water through electrochemical reactions without the need for high temperatures or additional energy inputs, significantly reducing energy consumption.

- Direct Capture and Utilization: Implements an electrochemical capture and conversion approach that enables self-enrichment and direct utilization of CO₂, enhancing efficiency and lowering operational costs.

- Flexible Processing Scale: The CO₂ processing capacity of a single stack ranges from 50 to 2000 tons per year, making it suitable for varying production demands.

- High-Quality Syngas Products: The purity of the syngas can reach over 85%, with a carbon-hydrogen ratio between 0.2/1 and 1/1, ideal for subsequent chemical synthesis.

- Long Service Life: The electrodes have a lifespan of 5 to 7 years, reducing maintenance frequency and costs.

Applications:

The electrolytic CO₂ to syngas technology is widely applied in the following fields:

- Chemical Industry: Syngas serves as a crucial raw material for the production of high-value products such as synthetic fuels, methanol, and olefins.

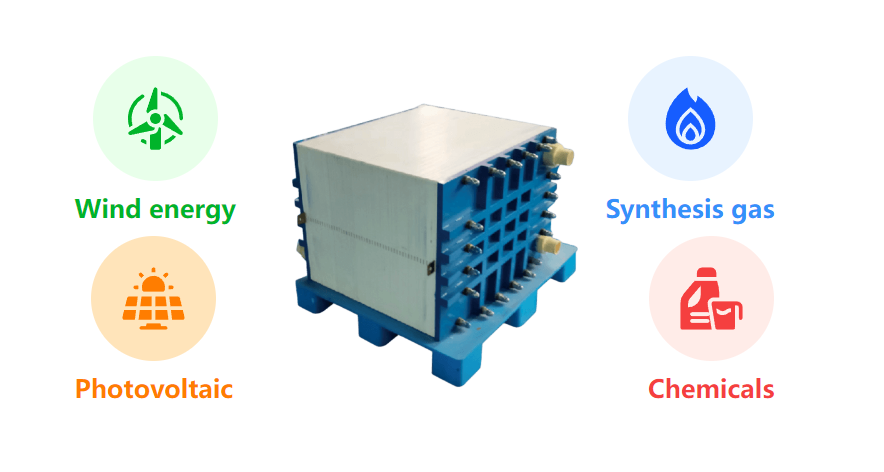

- Renewable Energy: When combined with renewable energy sources like wind and solar, it enables effective energy utilization and conversion, promoting sustainable development.

- Environmental Protection: By converting atmospheric CO₂ into usable chemical feedstocks, this technology helps mitigate global warming and climate change issues.

| Parameter | Value |

| Single Stack CO₂ Treatment Scale | 50-2000 t/year |

| Applicable CO₂ Concentration | 10-100 % |

| Syngas Purity | ≥85 % |

| Syngas Carbon-Hydrogen Ratio | 0.2/1-1/1 CO/H₂ |

| Syngas Electricity Consumption | ≤6.5 kWh/Nm³ |

| Electrode Lifespan | 5-7 years |

Enerke Low Carbon Tech Corp

Enerke Low Carbon Tech Corp