CONTACT US

Product Overview

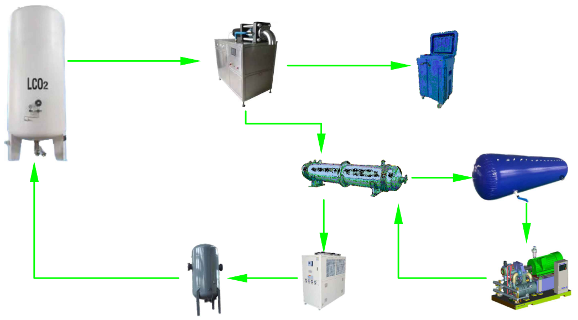

The Dry Ice Exhaust Gas Recovery System is an efficient recovery technology designed to minimize the waste of liquid carbon dioxide during dry ice production. In the production of dry ice, liquid carbon dioxide is injected into the dry ice manufacturing machine and compressed to form solid dry ice; however, this process generates a significant amount of gaseous carbon dioxide. Through techniques such as liquefaction and separation, this system can recover these exhaust gases and convert them into food-grade liquid carbon dioxide products. For every ton of dry ice produced, approximately 1.2 tons of liquid carbon dioxide can be recovered, significantly reducing the cost of dry ice production.

Product Features

- Advanced and Mature Technology: Simple process flow with stable and reliable operation, demonstrating strong adaptability.

- High Economic Efficiency: The equipment consumes less electricity and delivers liquid rapidly, resulting in low operating costs and reduced production expenses.

- High Automation: The system supports remote monitoring via a network, eliminating the need for manual supervision and enhancing operational efficiency.

- Customized Design: Capable of tailoring the process design and optimization according to the user's specific requirements.

Applications

- Dry Ice Production Industry: Facilitates carbon capture and utilization, enhancing energy efficiency and effectiveness.

- Beer Fermentation Industry: Recovers exhaust gases generated during the beer fermentation process and converts them into high-purity liquid carbon dioxide.

- Food Processing: Serves as a food-grade carbon dioxide raw material for food preservation and packaging.

- Chemical and Pharmaceutical Industries: Acts as an important industrial raw material and reaction gas.

| CO₂ Equipment Specifications | ||||

| Model | Production (tCO₂/h) | CO₂ Purity | Power Consumption (kW/tCO₂) | Footprint (m²) |

| CO2-2.4K | 0.3 | 99.99% | 250 | 6*12 |

| CO2-1W | 1.2 | 99.99% | 230 | 12*24 |

| CO2-2W | 2.5 | 99.99% | 220 | 12*24 |

| CO2-3W | 3.7 | 99.99% | 210 | 12*30 |

| CO2-4W | 5 | 99.99% | 200 | 12*36 |

| CO2-10W | 10 | 99.99% | 190 | 15*40 |

| Note: Parameters may vary depending on the source of carbon dioxide gas. | ||||

woboenerkeco

woboenerkeco