CONTACT US

Product Overview

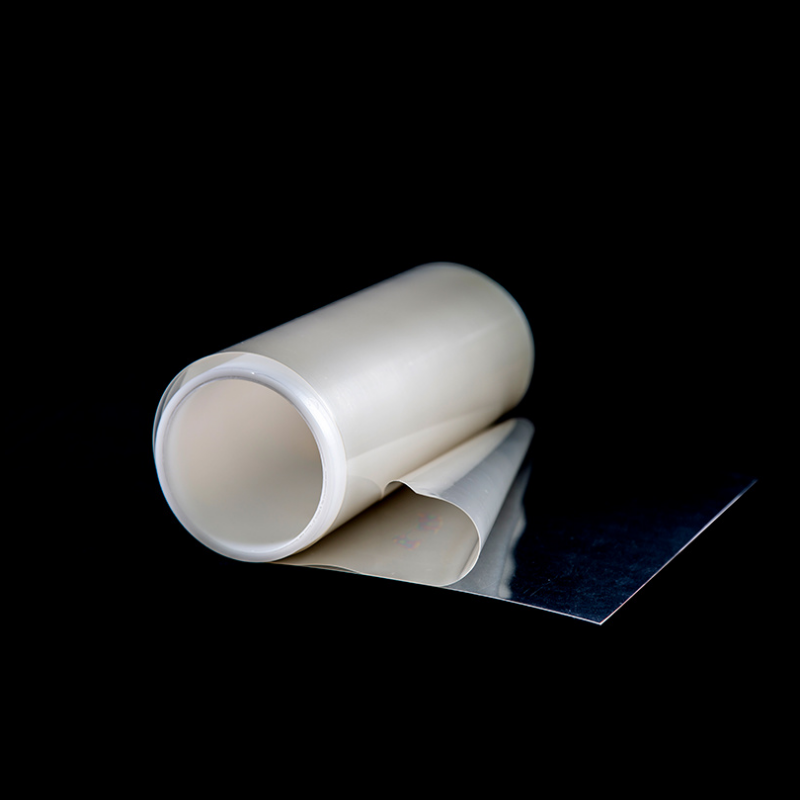

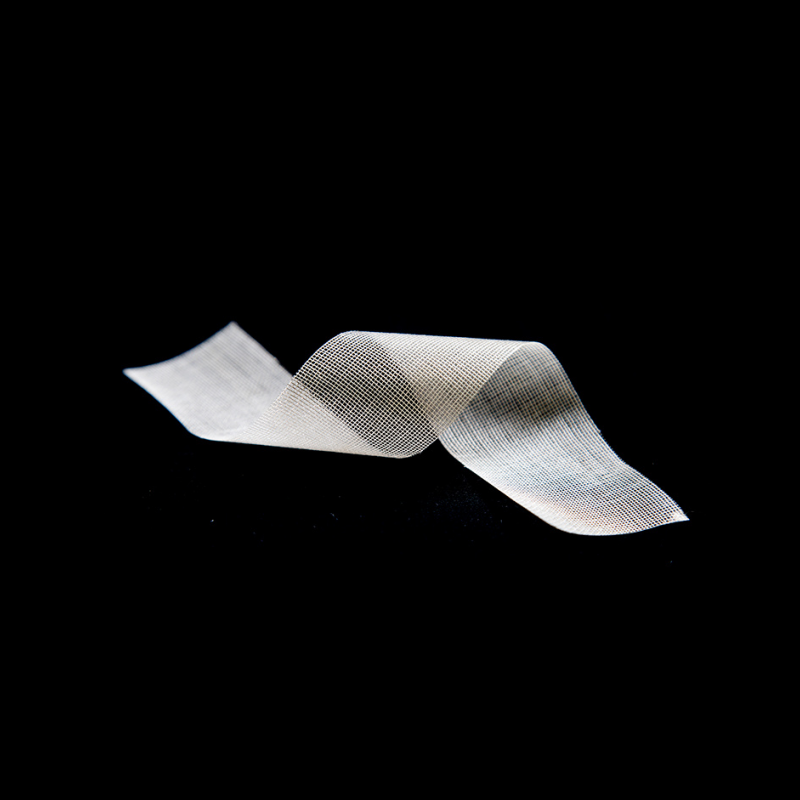

The composite proton exchange membrane is an advanced membrane material known for its low cost, high ionic conductivity, excellent mechanical strength, dimensional stability, and superior physical and chemical durability. These outstanding properties make the composite PEM highly applicable in clean energy fields such as fuel cells and water electrolysis for hydrogen production.

Product Features

- Low Cost, High Performance: Compared to traditional commercial proton exchange membranes, the composite membrane maintains excellent conductivity and strength at a lower cost.

- High Ionic Conductivity: Optimized design ensures high ionic conductivity even under low humidity conditions, maintaining performance.

- Excellent Mechanical Strength and Ductility: Tensile strength reaches 28.6 MPa (MD direction) and 35.0 MPa (TD direction), with a break elongation of up to 465%, showing excellent durability.

- Low Hydrogen Permeability: Extremely low hydrogen permeability (<0.006 ml/min·m²), significantly improving safety.

- Outstanding Hydration Properties: Low water absorption and swelling rates ensure dimensional stability and long-term performance in various working environments.

Applications

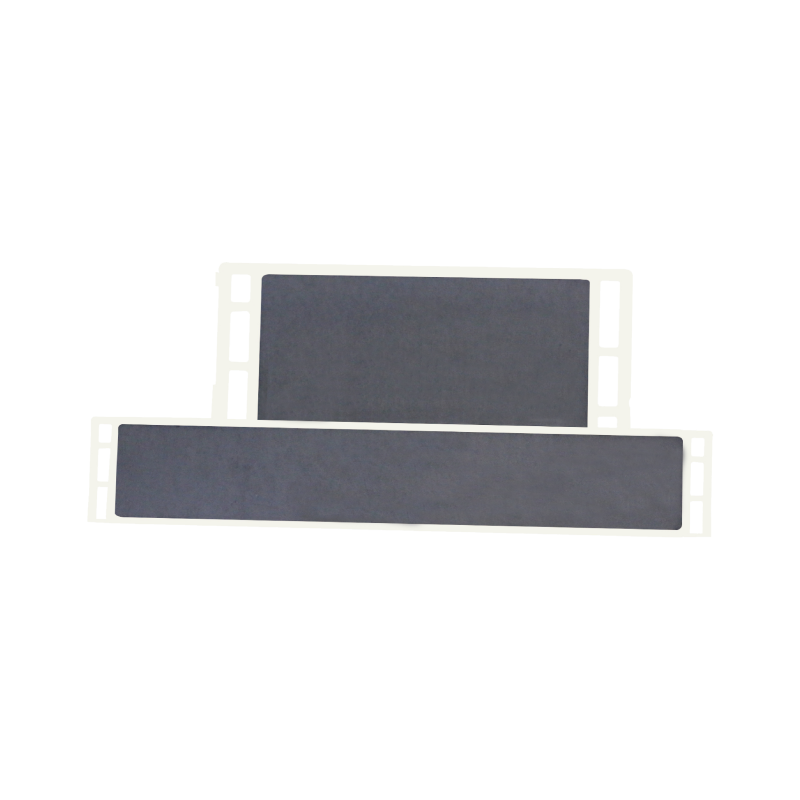

- Fuel Cells: Used in hydrogen-powered fuel cells, providing efficient proton conductivity and long service life.

- Water Electrolysis for Hydrogen Production: The composite membrane offers excellent conductivity and stability, improving hydrogen production efficiency in water electrolysis.

- Clean Energy Technologies: Has broad application potential in various clean energy technologies, such as CO₂ reduction and hydrogen storage.

| Property | WB PEMs | Commercial PEM |

| Thickness (μm) | 16.8 | 50.8 |

| Basis Weight (g/cm²) | 24.5 | 100 |

| Tensile Strength (MPa) | 28.6 (MD) / 35.0 (TD) | 32 (MD) / 32 (TD) |

| Elongation to Break (%) | 465 | 352 |

| Ion-exchange Capacity (meq/g) | 0.7 | 0.92 |

| Hydrogen Crossover (ml/min-m²) | <0.006 | <0.010 |

| Water Uptake (%) | 4 (23°C) / 15 (100°C) | 5 (23°C) / 50 (100°C) |

| Linear Expansion (%) | 4 (23°C) / 6 (100°C) | 10 (23°C) / 15 (100°C) |

| Proton Conductivity (S/cm) | Through-plane: 0.065 In-plane: 40 |

- |

woboenerkeco

woboenerkeco