CONTACT US

Product Overview

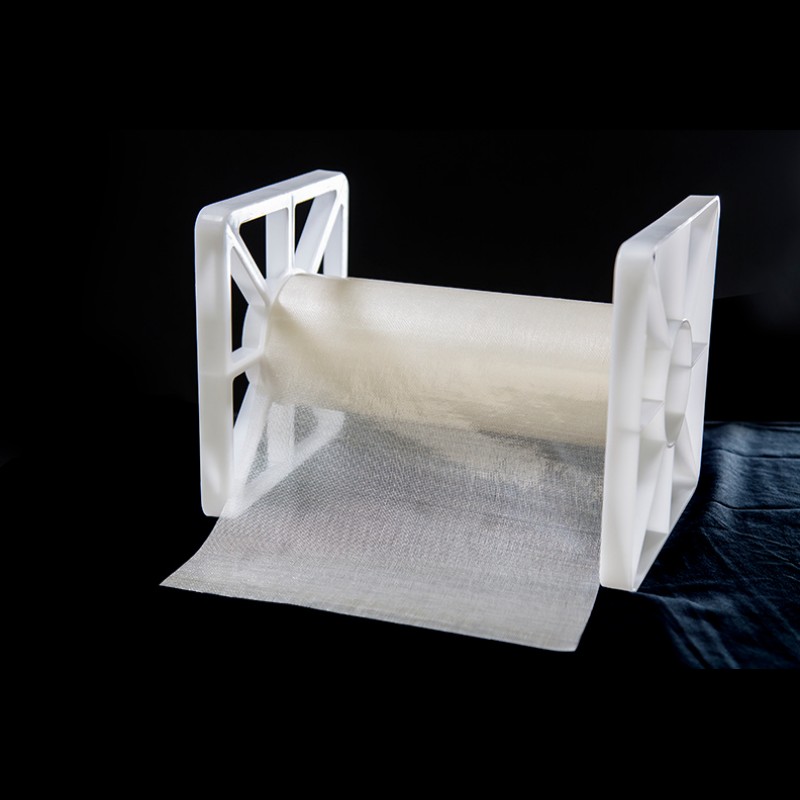

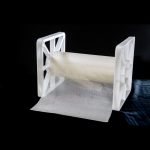

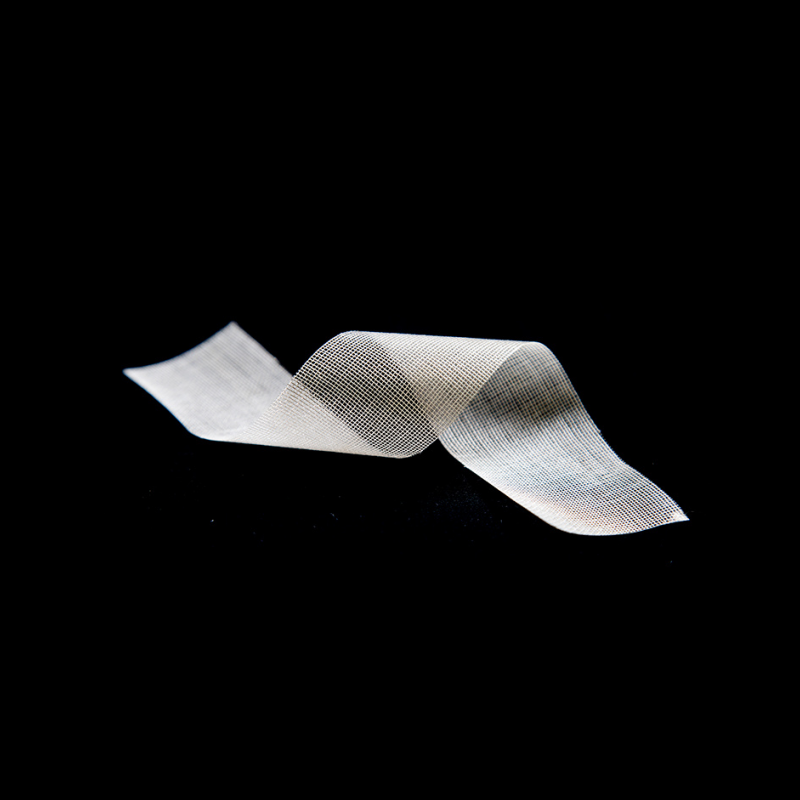

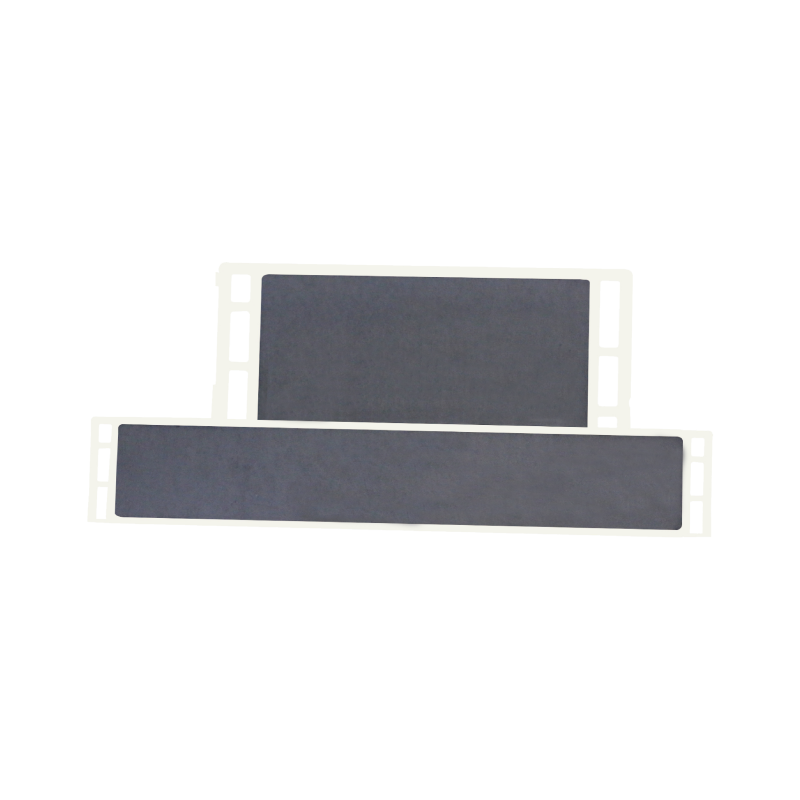

The composite ion exchange membrane for electrolysis and electroplating is a high-performance membrane reinforced with a high-strength PTFE mesh layer and made from perfluorosulfonic acid resin with a specific molecular weight and ion exchange capacity. With uniform thickness and excellent conductivity, this membrane is widely used in applications such as chlorine dioxide generators, copper recovery from etching solutions, gold salt preparation, amino acid refinement, caustic soda production, and electrodialysis in electrolysis and electroplating industries.

Product Features

High-Strength Structure: Reinforced with a PTFE mesh layer to enhance durability and structural integrity.

Excellent Conductivity: Conductivity of >0.100 S/cm for fast ion transfer, boosting production efficiency.

Low Swelling Rate: Maintains dimensional stability under high temperature and humidity, reducing deformation.

Wide Chemical Resistance: Highly resistant to strong acids and bases, adaptable to diverse electrolysis and electroplating conditions.

Applications

Chlorine Dioxide Generators: Ensures stable ion exchange for efficient chlorine dioxide production via electrolysis.

Etching Solution Recovery and Precious Metal Preparation: Supports efficient recovery and preparation of copper, gold salts, and other materials.

Amino Acid Refinement: Facilitates purification of amino acids and other organic compounds.

Caustic Soda Production and Electrodialysis: Provides reliable ion conduction and durability in caustic soda manufacturing and electrodialysis processes.

| Model | Thickness (μm) | Grammage (g/m²) |

| N-417 | 260 | 340 |

| N-4110 | 360 | 470 |

| Property | Specification | Test Method |

| Tensile Strength (MPa) | >40 | GB/T 20042.3-2022 |

| Elongation at Break (%) | 3100 | GB/T 20042.3-2022 |

| Density | 1.35 | — |

| Property | Specification | Test Method |

| Conductivity (S/cm) | >0.100 | GB/T 200423-2022 |

| Acid Capacity (meq/g) | 1.00±0.05 | GB/T 200423-2022 |

| Property | Specification | Test Method |

| Moisture Content (%) | 5.0±3.0 | GB/T 20042.3-2022 |

| Water Absorption (%) | 50.0±5.0 | GB/T 20042.3-2022 |

| Thickness Swelling Rate (23°C, 50% RH) | ≤5 (23°C) from 50% RH | GB/T 200423-2022 |

| ≤10 (100°C) from 50% RH | GB/T 200423-2022 | |

| Linear Swelling Rate (23°C, 50% RH) | ≤2 (23°C) from 50% RH | GB/T 20042.3-2022 |

| ≤5 (100°C) from 50% RH | GB/T 20042.3-2022 |

woboenerkeco

woboenerkeco