CONTACT US

Product Overview

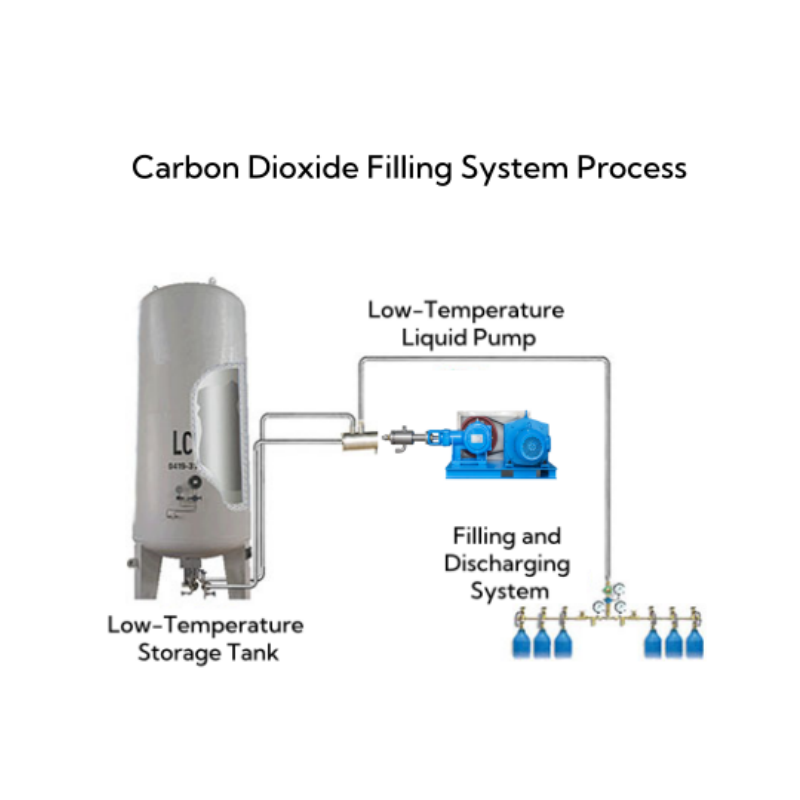

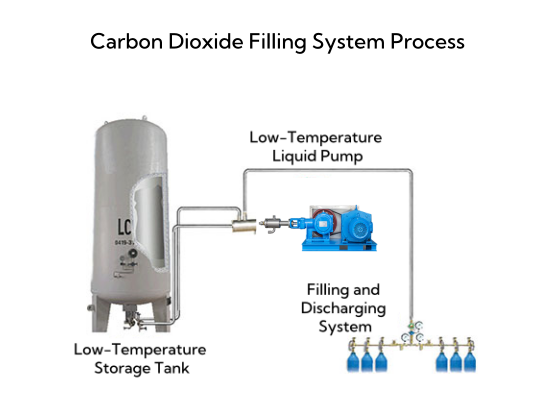

The carbon dioxide filling station is a facility specifically designed for the safe and accurate filling of liquid carbon dioxide into various containers (such as cylinders and storage tanks). The filling station receives liquid carbon dioxide from production manufacturers or suppliers and processes it to meet the needs of different users in industries such as food and beverage, firefighting, and welding.

Main Equipment Configuration

- Storage Tank: Equipped with large liquid carbon dioxide storage tanks, typically low-temperature, high-pressure containers with capacities ranging from several cubic meters to hundreds of cubic meters. These tanks are usually made of stainless steel or carbon steel and feature good insulation to minimize evaporation.

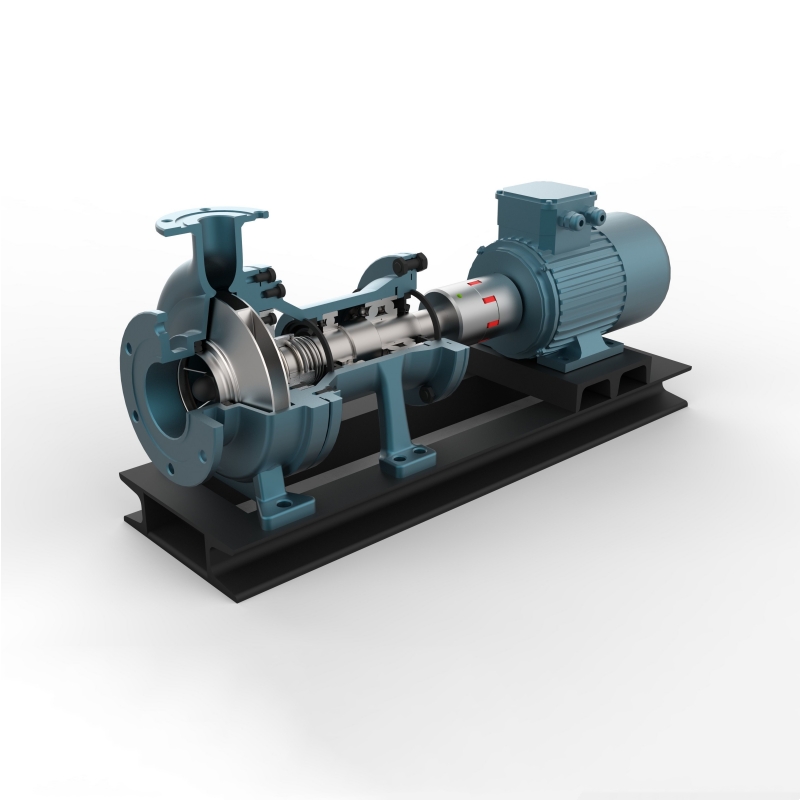

- Filling Pump: The filling pump is the core component, utilizing either a piston or diaphragm design, with flow rates ranging from several liters per minute to tens of liters per minute and pressure capabilities of 10-20MPa, ensuring smooth filling operations.

- Vaporizer: This device converts liquid carbon dioxide into gaseous form, with common types including air-heated vaporizers and water bath vaporizers, configured according to filling requirements.

- Weighing Equipment: High-precision electronic scales or platform scales are used to monitor the filling quantity in real time, ensuring accuracy in the filling process.

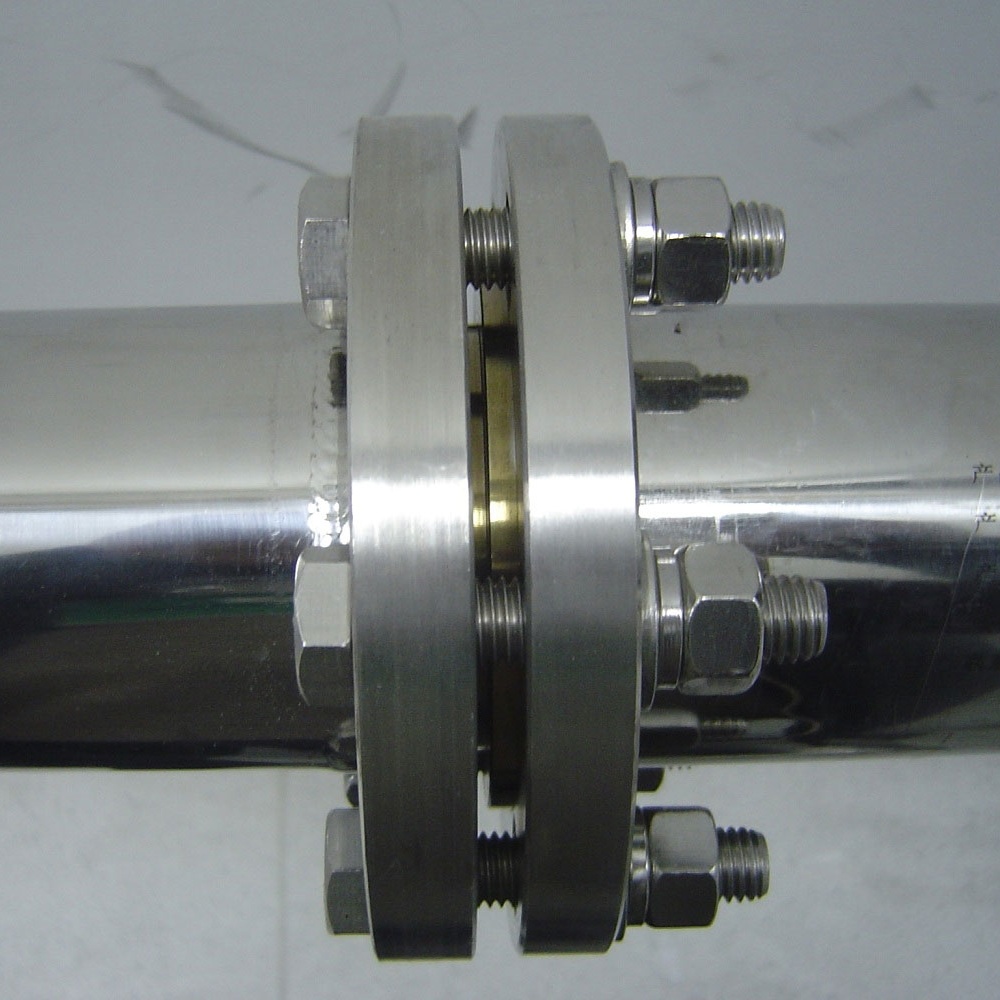

- Piping System and Valves: The system employs stainless steel piping, with valve designs that ensure flow direction and rate control, offering good sealing and corrosion resistance.

Applications

The carbon dioxide filling station is widely used in various fields, including:

- Food and Beverage Industry: For the production of carbonated beverages.

- Firefighting Industry: In the filling of fire extinguishers.

- Welding Industry: To supply gases for welding applications.

| Technical Parameters | |

| Suitable Medium | LCO2 |

| Control Pressure | ≤ 3.0 MPa |

woboenerkeco

woboenerkeco