CONTACT US

Product Overview

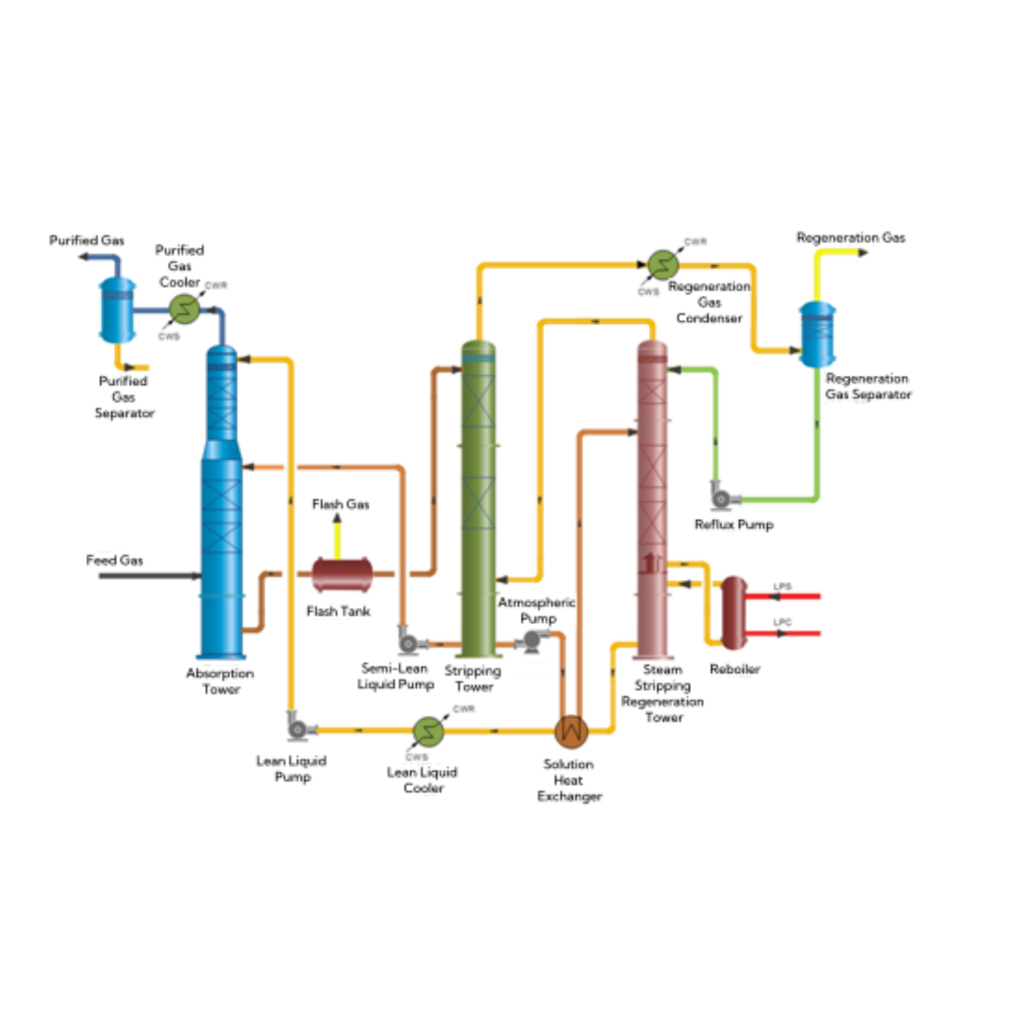

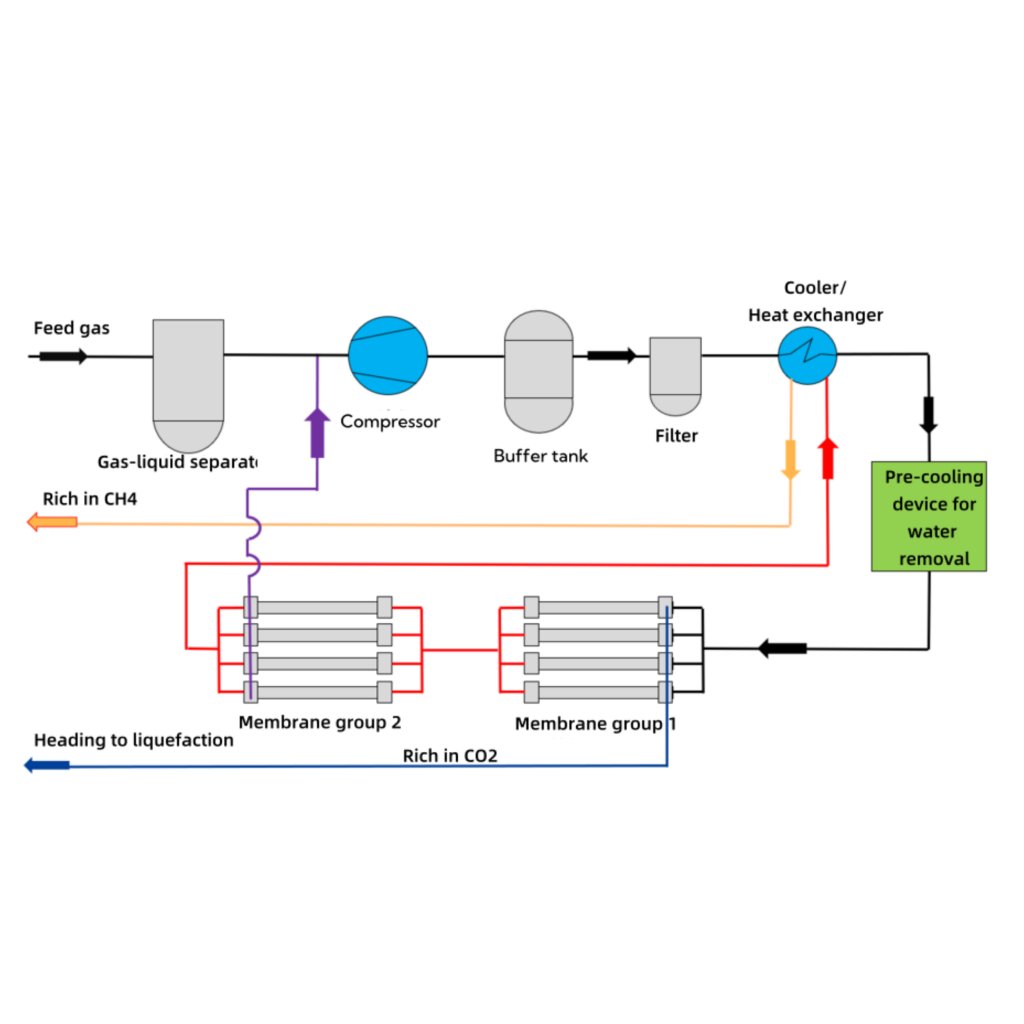

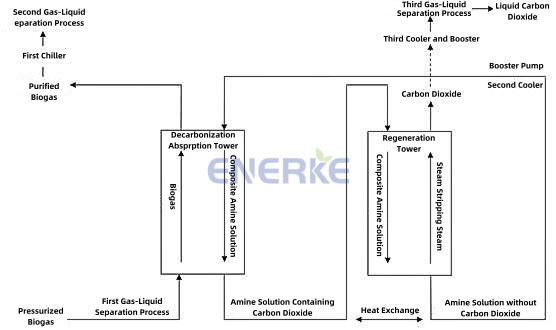

The biogas decarbonization and purification unit is a modular system that integrates biogas purification, compression, dehydration, membrane separation, and post-pressurization functions. Built on over 20 years of successful gas separation and compression technology, this unit is designed for efficient collaboration between multiple processes, including desulfurization, decarbonization, and pressurization, to meet the demands of biogas purification and utilization.

Product Features

- Modular Design: The system consists of modules for biogas desulfurization, biogas fans, decarbonization, natural gas pressurization, and refueling, facilitating easy installation, relocation, and maintenance.

- High Decarbonization Efficiency: Employs hollow fiber membrane separation technology, ensuring a methane (CH₄) recovery rate exceeding 95% and a target CO₂ content below 3%.

- Operational Flexibility: Handles flow rates ranging from 200 to 450 Nm³/h, with operational flexibility from 30% to 110%, accommodating varying production needs.

- Environmental and Energy Efficiency: Utilizes multi-screw compression technology to enhance processing efficiency and reduce energy consumption per unit of gas treated, supporting sustainable development.

Applications

- Biogas Utilization: Suitable for biogas purification and utilization in agriculture, wastewater treatment plants, and landfills, promoting resource recycling.

- Natural Gas Industry: Supports the subsequent treatment and utilization of natural gas, aiding the transition to clean energy.

- Environmental Projects: Applied in environmental initiatives to reduce greenhouse gas emissions, contributing to national and local government reduction targets.

| Parameter | Enerke-450 | Enerke-850 | Enerke-1250 | Enerke-2000 |

| Flow Rate Range (Nm³/h) | 200 – 450 | 500 – 850 | 900 – 1250 | 1500 – 2000 |

| Flow Operation Flexibility | 30% - 110% | 30% - 110% | 30% - 110% | 30% - 110% |

| CH₄ Recovery Rate | >95% | >95% | >95% | >95% |

| CO₂ Target Content | <3% | <3% | <3% | <3% |

| Inlet Pressure Range (kPa) | 10 – 30 | 10 – 30 | 10 – 30 | 10 – 30 |

| Outlet Pressure Range (barg) | 4 – 250 | 4 – 250 | 4 – 250 | 4 – 250 |

| Daily Capacity (m³) | 5000 – 10000 | 12000 – 20000 | 20000 – 30000 | 36000 – 50000 |

| Configuration | Variable frequency twin-screw (1 unit), air-cooled | Variable frequency twin-screw (2 units), air-cooled | Variable frequency twin-screw (3 units), air-cooled | Variable frequency twin-screw (2 large units), air-cooled |

woboenerkeco

woboenerkeco