CONTACT US

Product Overview

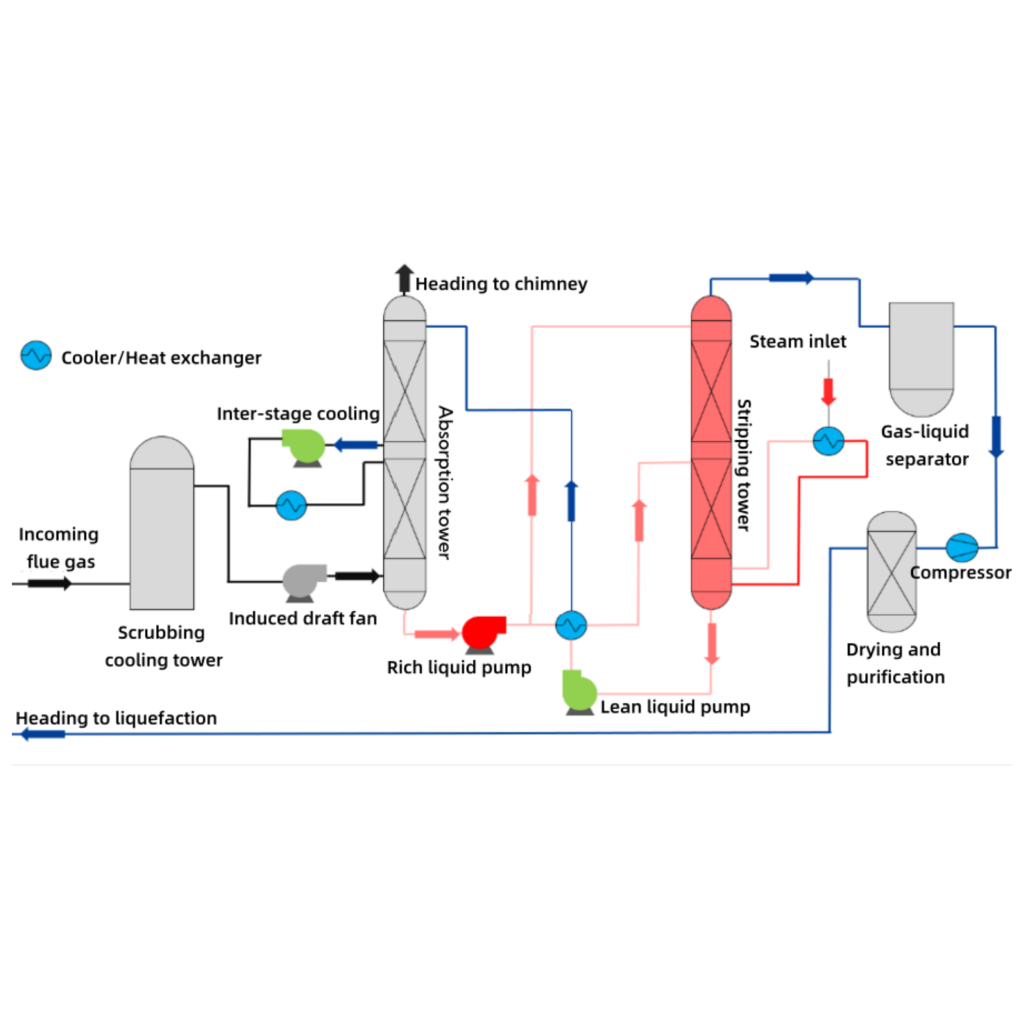

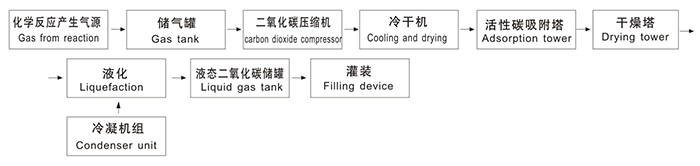

The acid-base neutralization CO₂ production system uses a chemical reaction between citric acid and sodium bicarbonate to generate carbon dioxide, citrates, and water. This system is especially suitable for regions with limited transportation and industrial infrastructure. Through multiple purification steps, the produced CO₂ gas is converted into high-purity liquid CO₂, which is widely used in the production of soft drinks and sparkling wines.

Product Features

- High CO₂ Recovery Rate: Achieves a CO₂ recovery rate of up to 90%, effectively utilizing the CO₂ generated from the chemical reaction.

- Multi-Stage Purification: Employs equipment such as refrigeration dryers, adsorption towers, and drying towers to ensure CO₂ purity reaches 99.97%-99.99%.

- Liquid Storage: CO₂ is condensed into liquid form at -18°C for easy long-term storage and on-demand gas supply.

- Stable Gas Supply: Provides a consistent CO₂ output pressure (0.5-0.7 MPa) to meet the needs of various industries.

Applications

- Beverage Manufacturing: Widely used in the production of soft drinks and sparkling wines, ensuring the CO₂ meets food-grade standards.

- Laboratory and Industrial Gas: Supplies high-purity CO₂ for laboratories and factories, fulfilling the gas needs of industrial production.

- Gas Supply in Remote Areas: Offers a stable and reliable CO₂ production method in regions with weak industrial infrastructure, supporting local gas demands.

| Parameter | Details |

| CO₂ Gas Production Capacity | 50 kg/h |

| CO₂ Recovery Rate | ≥90% |

| Normal Operating Pressure | 2.0 MPa |

| Liquid CO₂ Storage Temperature | -18 °C |

| Liquid CO₂ Storage Tank Volume | 1 m³ |

| Purity of CO₂ after Treatment | 99.97% - 99.99% |

| CO₂ Gas Output Pressure | 0.5 - 0.7 MPa |

| CO₂ Source Purity | 99.50% |

| Water Pressure | ≥0.2 MPa |

| Power Supply | 3P-380V-50Hz |

| Installed Capacity | 20 kW |

| Reference Table for Feed Ratios | ||||||

| Item | Feed Amount (kg/batch) | Notes | ||||

| Ⅰ | Ⅱ | Ⅲ | Maximum feed amount per operation | Feed Locations | ||

| C6H8O7(98%) | 60 | 120 | 190 | Industrial use, free of solid impurities | Citric Acid Tank | |

| NaHCO3(99.5%) | 180 | 360 | 570 | Mix into a paste | Reaction Kettle | |

| H2O | 200 | 400 | 600 | |||

| NaOH | 1.5 | 2 | 3 | Prepare 30 liters of 5-10% sodium hydroxide solution | Primary Filter Tank | |

| KMnO4 | 0.6 | 0.8 | 1 | Prepare 30 liters of 2-3% potassium permanganate solution | Gas Washing Tank | |

| FeSO4 | 1 | 2 | 3 | Prepare 30 liters of 5-10% solution | Gas Washing Tank | |

| CO₂ Production | kg | 79.2 | 158.4 | 237.6 | Volume at standard conditions | |

| m3 | 40.56 | 81.12 | 121.68 | |||

| Reference Carbonation Levels for Various Soft Drinks | |||||

| Product | Carbonation Level (Volume Ratio) |

Product | Carbonation Level (Volume Ratio) |

Product | Carbonation Level (Volume Ratio) |

| Ice Cream Soda | 1.5 | Lemon Soda | 2.5-3.5 | Sarsaparilla Soda | 3.5-4 |

| Orange Soda | 1.5-2.5 | White Lemon Soda | 2.5-3.5 | Malt Extract Soda | 2.5-4 |

| Pineapple Soda | 1.5-2.5 | Cherry Soda | 2.5-3.5 | Lemon Soda | 3.5-4 |

| Grape Soda | 1.5-2.5 | Ginger Soda | 2.5-3.5 | Soda Water | 4-5 |

| Apple Soda | 1.5-2.5 | Cola Soda | 3.5-4 | Mineral Water | 4-5 |

| Strawberry Soda | 1.5-2.5 | Dry Ginger Soda | 3.5-5 | ||

woboenerkeco

woboenerkeco