CONTACT US

Product Introduction

The pellet dry ice machine is an efficient, energy-saving, and easy-to-operate dry ice production device, specifically designed to produce pellet dry ice. This machine utilizes an advanced automatic control system, a hydraulic system, and high-efficiency cooling technology, ensuring stable operation under varying climatic conditions. It produces high-density pellet dry ice, which is widely used in cleaning, refrigeration, cooling, and other applications. Its compact design significantly saves space, occupying only half the area of similar equipment. Additionally, it is highly durable and cost-effective to maintain, making it an ideal dry ice production machine for industrial applications.

Product Features

- Compact Design, Space-Saving: The machine's compact design takes up just half the space of similar equipment, saving valuable production floor space. It is suitable for businesses of various sizes.

- Reliable Control System: Equipped with a CPU-based automatic control system and imported hydraulic components, the machine is highly stable and reliable, ensuring long-term efficient operation.

- Adaptable to Low-Quality CO₂: The design includes a specialized unit that allows the machine to operate even when the CO₂ source has excessive moisture, ensuring flexibility with different gas conditions.

- Energy-Efficient Cooling System: The cooling system uses residual gas from the production process to cool the hydraulic oil tank, eliminating the need for external cooling water. This extends the machine's lifespan. The small 120L oil tank also reduces oil replacement costs and maintains the oil temperature between 40-50°C.

- Interchangeable Molds: The machine supports interchangeable molds, allowing the production of various pellet sizes to meet different application needs.

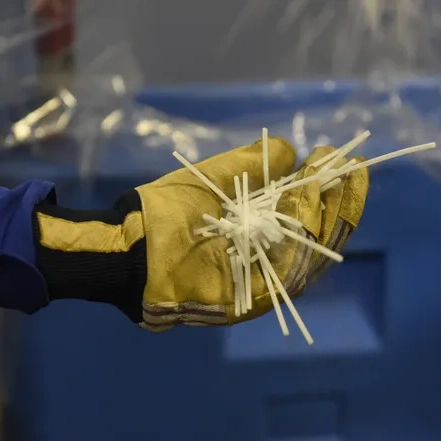

- High-Density Pellet Dry Ice: The machine produces high-density, stable-quality pellet dry ice, meeting the requirements for industrial cleaning, refrigeration, and cooling.

Applications

- Dry Ice Cleaning: Suitable for industrial cleaning in fields such as tire production, precision casting, printing, engine maintenance, etc. It serves as the material for dry ice blasting, effectively removing dirt from equipment surfaces.

- Refrigeration & Cooling: Used in cold chain logistics and food transportation to keep food, pharmaceuticals, and other goods at low temperatures during transit.

- Food & Entertainment Industry: Widely used in the food and entertainment sectors to create fog effects for events like weddings, parties, and themed activities, enhancing the atmosphere.

- Industrial Use: Applied for cooling and temperature reduction during industrial production processes, helping to prevent equipment overheating and maintain production stability.

- Special Effects: Pellet dry ice can also be used to create smoke effects, cooling effects, and purify environments, making it ideal for various visual and atmospheric effects in different venues.

| Model | EN-K-50-1 | EN-K-100-1 | EN-K-200-1 | EN-K-300-1 | EN-K-400 | EN-K-600 | EN-K-1000 | EN-K-1500 | EN-K-2000 |

| Motor Power (kW) | 3.7 | 5.5 | 11 | 15 | 15 | 18.5 | 22 | 30 | 37 |

| Dry Ice Specifications (mm) | Φ3-Φ16 | Φ3-Φ16 | Φ3-Φ19 | Φ3-Φ19 | φ3-φ25 | ||||

| Dry Ice Production (kg/h) | 50-60 | 100-120 | 180-200 | 270-300 | 400 | 600 | 1000 | 1500 | 2000 |

| Dry Ice Density (t/m³) | ≥1.50 | ≥1.50 | ≥1.50 | ≥1.50 | ≥1.52 | ||||

| CO₂ Conversion Rate | ≥38% | ≥38% | ≥42% | ≥42% | ≥42% | ||||

| Inlet Pressure (MPa) | ≤2.1 | ≤2.1 | ≤2.1 | ≤2.1 | 1.7~2.2 | ||||

| Inlet Diameter (mm) | DN10 | DN10 | DN20 | DN20 | DN20 | DN25 | |||

| Exhaust Pipe Diameter (mm) | DN 50 | DN50 | DN70 | DN70 | 2-DN65 | 2-DN80 | |||

| Oil Tank Capacity (L) | 90 | 200 | 280 | 280 | 250 | 280 | 300 | 420 | 450 |

| Machine Dimensions (cm) | 160×80×130 | 160×140×170 | 270×110×180 | 270×150×180 | 175×140×185 | 215×140×185 | 215×140×185 | 396×150×320 | 396×150×320 |

| Total Weight (kg) | 600 | 750 | 1300 | 1700 | 2100 | 2400 | 2500 | 4000 | 4500 |

woboenerkeco

woboenerkeco