CONTACT US

Product Introduction

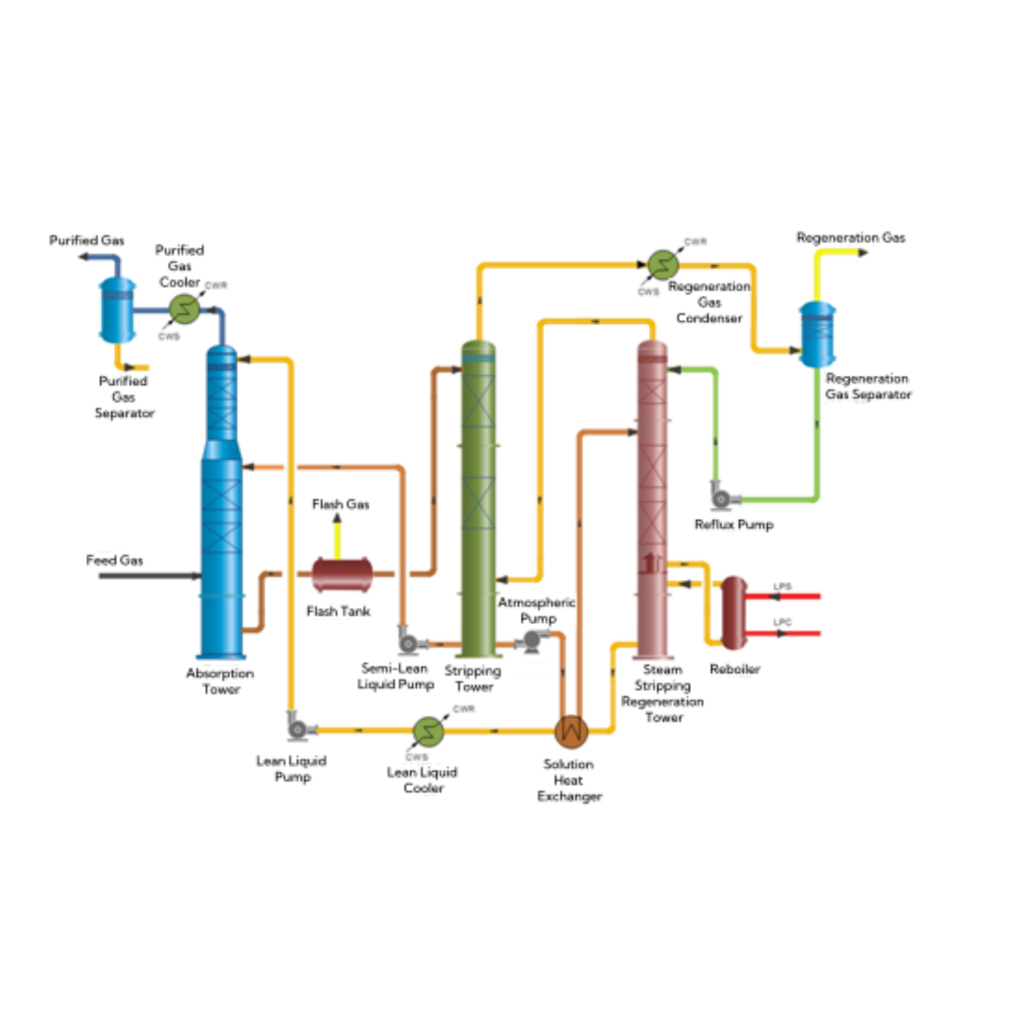

The molecular sieve purification skid is an efficient gas purification device that utilizes solid adsorbents (such as molecular sieves, silica gel, and activated alumina) to adsorb impurities like moisture, benzene, and H₂S from gases, thereby achieving gas purification. This device enables the recycling of regenerated gas, avoiding discharge losses and is suitable for various gas treatment needs.

Product Features

- Simple Process: Employs mature molecular sieve purification technology, ensuring a straightforward and reliable process.

- High Automation: Features an automated control system for easy operation, enhancing work efficiency.

- Space-Saving: The compact design minimizes the footprint, resulting in lower investment costs and shorter payback periods.

- Flexibility: Purification processes can be tailored based on actual working conditions, with options for two-tower, three-tower, or multi-tower configurations to meet different purification requirements.

Applications

- Natural Gas Treatment: Widely used for dehydrating and hydrocarbon removal from natural gas, improving its purity and quality.

- Air Drying: Effectively removes moisture and impurities from air, utilized for drying and purifying industrial gases.

- Coke Oven Gas Treatment: Employed for the removal of benzene and naphthalene from coke oven gas, enhancing its quality.

- Hydrogen Purification: Suitable for drying and purifying hydrogen gas, meeting the demand for high-purity hydrogen.

- Other Industrial Gases: Capable of processing various industrial gases, including industrial gases and biogas, with strong adaptability.

| Parameter | Description |

| Treatment Gas Volume | 100 ~ 50,000 Nm³/h |

| Working Pressure | 0.3 ~ 25 MPa |

| Process Medium | Industrial gases, natural gas, biogas, coke oven gas, hydrogen |

woboenerkeco

woboenerkeco