CONTACT US

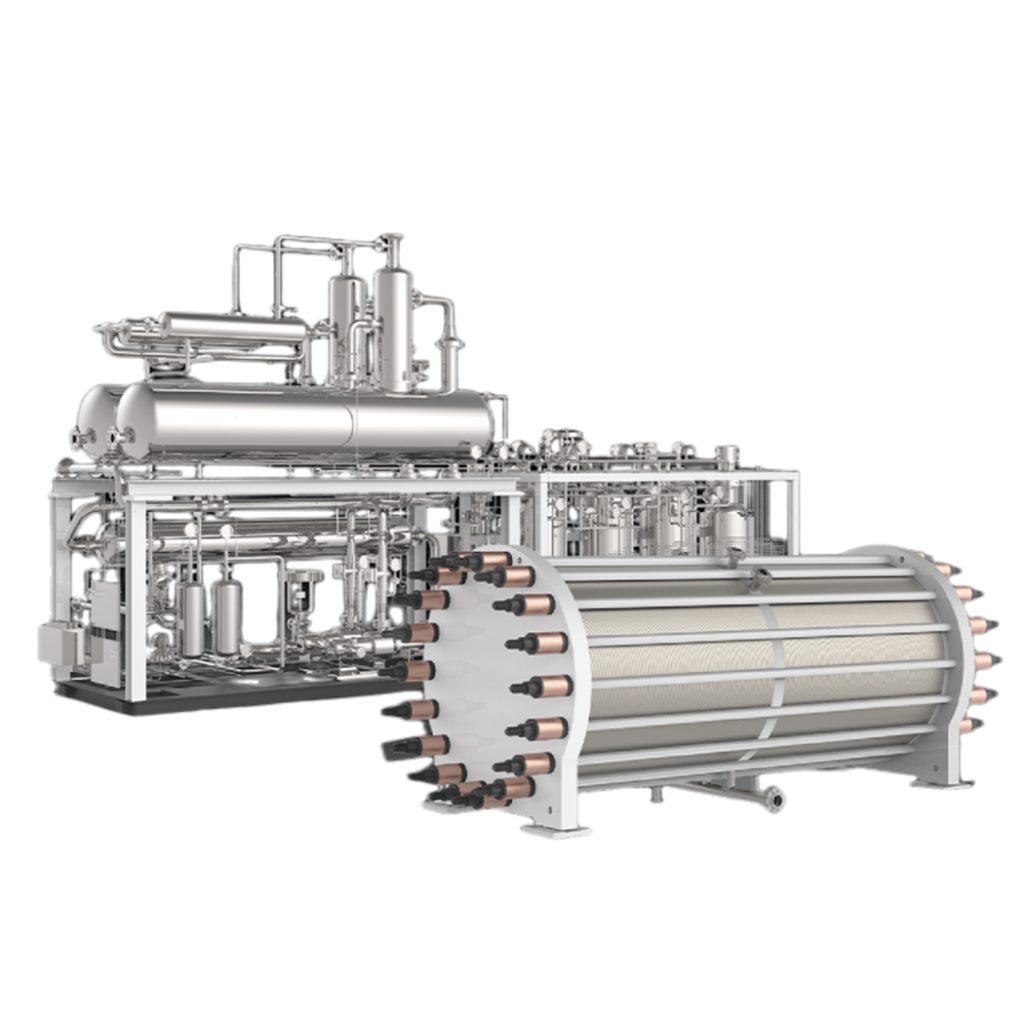

Product Overview

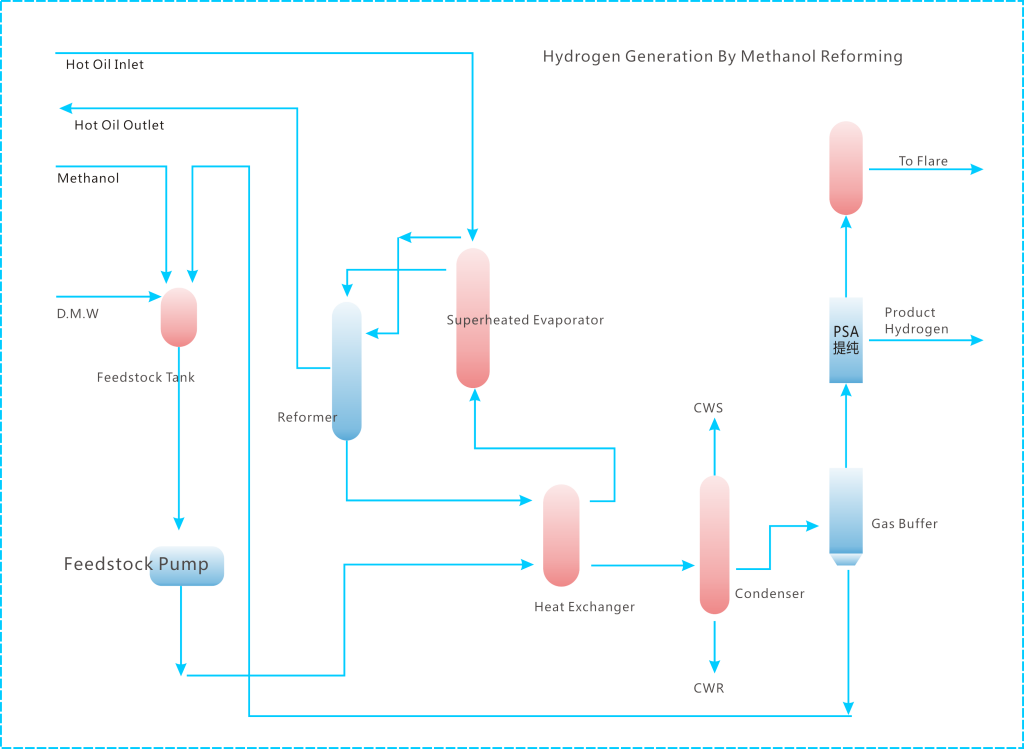

The Methanol Reforming Hydrogen Production Unit utilizes methanol reforming with pressure swing adsorption (PSA) technology to produce hydrogen. Using methanol and water as feedstocks, methanol is decomposed into a hydrogen-rich gas mixture under specific temperature and pressure conditions with the help of catalysts, followed by PSA purification to obtain high-purity hydrogen. This mature, reliable technology offers a streamlined process ideal for large-scale hydrogen production and meets diverse industrial demands.

Key Features

- Proven Production Technology: Established, safe, and reliable technology with broad applications across various industries.

- Convenient Feedstock Supply: Methanol is widely available, easy to transport and store, and cost-effective.

- High Automation: Compact design with a high degree of automation for simple operation and minimal space requirements.

- Efficient and Economical: Low energy consumption, cost-effective hydrogen production with minimal investment and a short payback period.

- Environmentally Friendly: Clean production with no environmental pollution, aligning with clean energy standards.

Application Areas

- Industrial Hydrogen Production: Ideal for large-scale hydrogen production in chemical, petroleum refining, and other industries.

- Clean Energy: Supplies hydrogen for new energy applications such as fuel cell vehicles.

- Distributed Energy Systems: Supports hydrogen production in distributed energy networks, aiding energy storage and conversion.

| Parameter | Range |

| Capacity | 30~100000 Nm³/h |

| Purity | 99%~99.999% |

| Pressure | 0.8~2.5 MPa |

woboenerkeco

woboenerkeco