CONTACT US

Product Overview

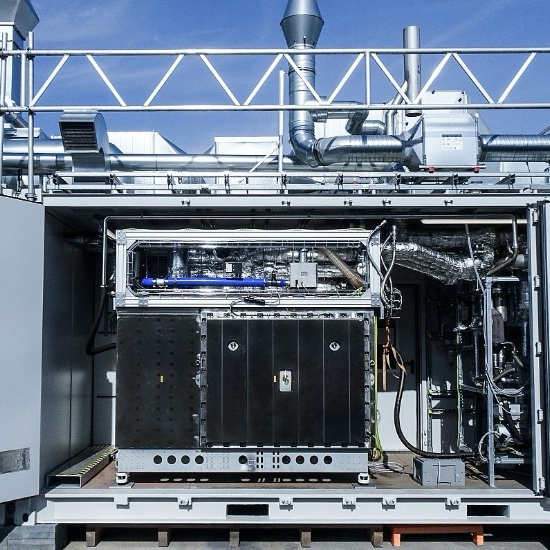

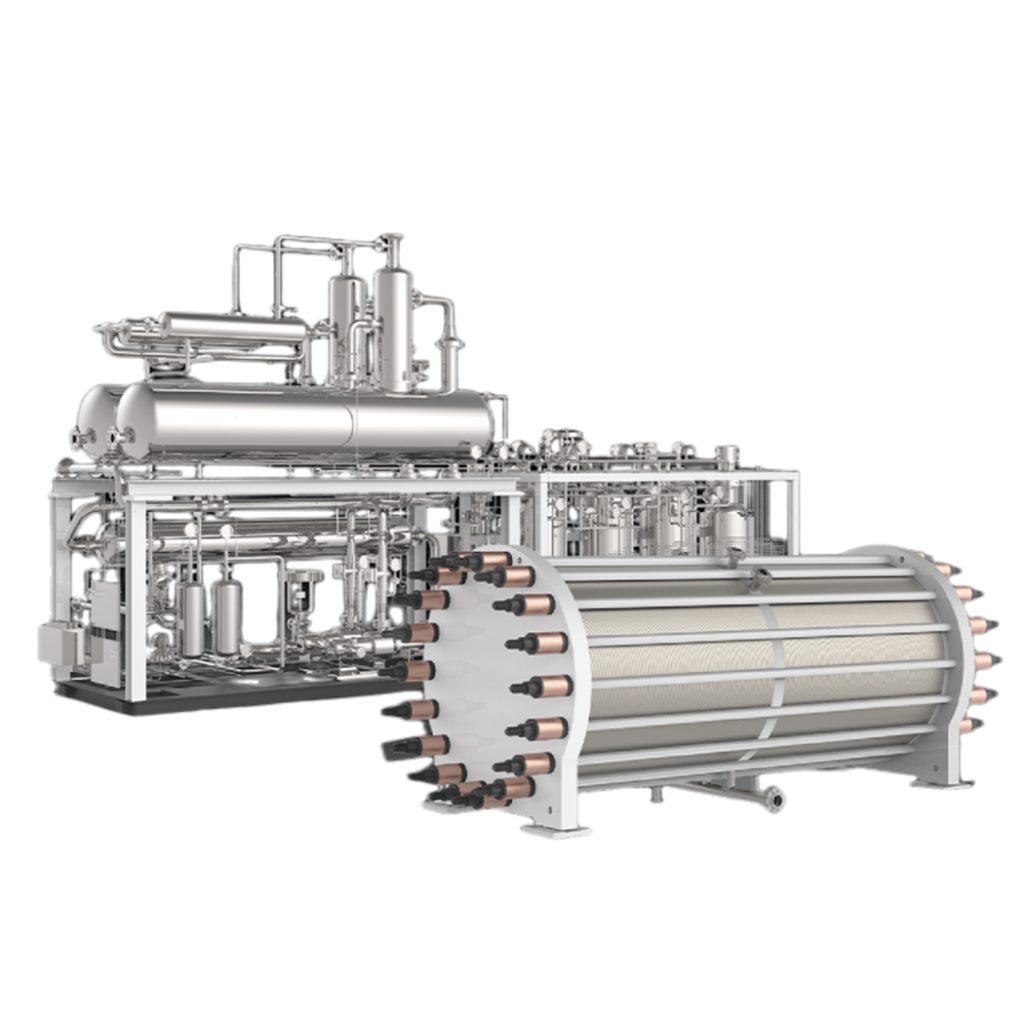

The SOEC (Solid Oxide Electrolysis Cell) Water Electrolysis Hydrogen Production System features a modular, skid-mounted design, offering a compact structure and easy installation with a small footprint, significantly reducing on-site construction requirements. The system is highly adaptable, allowing for scalable hydrogen production according to demand and the integration of external heat sources. Particularly suited for scenarios involving industrial waste heat or solar thermal energy, this system utilizes thermoelectric coupling to further reduce energy consumption for hydrogen production, making it an ideal solution for efficient and clean hydrogen generation.

Key Features

- Modular Design: Allows flexible expansion and configuration, enabling scalability of hydrogen production to meet various needs and applications.

- Skid-Mounted Installation: High level of integration reduces on-site installation time and costs, offering a streamlined and efficient setup.

- External Heat Integration: Supports the use of industrial waste heat, residual heat, or solar thermal energy as an external heat source, enhancing efficiency by lowering the system's energy consumption through thermoelectric coupling.

- Compact Layout: Space-saving design is ideal for deployment in locations with limited area.

Application Areas

- Industrial Waste Heat Utilization: Ideal for high-temperature industrial processes (e.g., steelmaking, petrochemicals), enabling low-energy hydrogen production by tapping into waste heat, thus enhancing energy efficiency.

- Renewable Energy Hydrogen Production: Suitable for renewable energy sources like wind and solar power, using intermittent power to drive hydrogen production and support clean energy storage and conversion.

- New Energy Transportation: Provides a clean, efficient hydrogen production pathway for hydrogen fuel cell vehicles and other hydrogen applications, supporting infrastructure like hydrogen refueling stations.

- Integrated Energy Systems: In integrated energy scenarios (e.g., energy internet), it enables efficient conversion and storage of power and thermal energy through thermoelectric hydrogen production, enhancing overall system efficiency.

| Hydrogen Production Parameters: | WOBO-100 | WOBO-1000 |

| Hydrogen Production Rate | 100 Nm/h | 1000 Nm3/h |

| Power Load Range | 0%~120% | 0%~120% |

| Thermal Startup Time | <2min | <5min |

| Hydrogen Outlet Pressure | 1.6MPa (g) | 1.6MPa(g) |

| Hydrogen Purity | up to 99.99% | up to 99.99% |

| System Rated Power (AC) | 360kW | 3600kW |

| Stack Energy Consumption (DC)* | 3.16kWh/Nm3 | 3.16 kWh/Nm3 |

| System Energy Consumption (AC)* | 3.6kWh/Nm3 | 3.6kWh/Nm3 |

| System Efficiency | 84% | 84% |

| Steam Inlet Volume | 134kg/h | 1340 kg/h |

| Inlet Temperature | 140℃ | 140℃ |

| Inlet Pressure | >1.5 bar(g) | >1.5 bar(g) |

| Weight | 6t | 60t |

| Footprint | ~50m2 | ~400m2 |

| Ambient Temperature | -20°C~40°C | -20°C~40°C |

woboenerkeco

woboenerkeco