CONTACT US

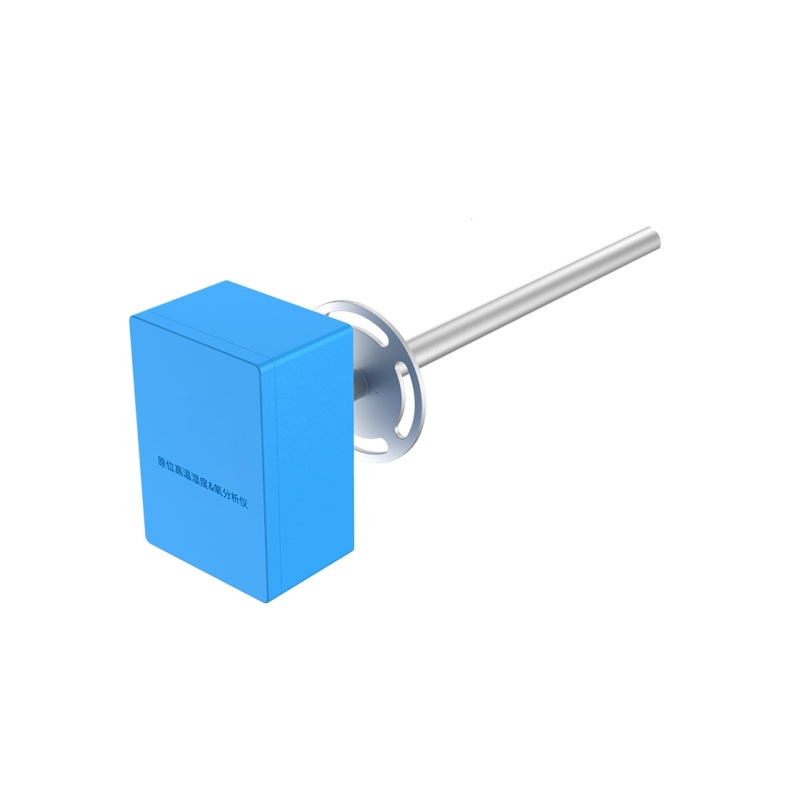

Product Overview

The In-Situ High-Temperature Humidity & Oxygen Analyzer adopts internationally advanced solid-state ceramic electrolytic sensor technology for wet and dry oxygen measurement, combined with the extreme current measurement method for humidity. It is specifically designed for online monitoring of flue gas humidity and oxygen concentration in high-temperature and highly corrosive environments. This instrument can operate stably in temperatures up to 500°C and features excellent corrosion resistance, fast response, and high-precision measurement capabilities. It is particularly suitable for harsh conditions involving volatile organic compounds (VOCs) that contain heavy metals, high corrosion, high humidity, and complex organic interference. Compliant with the HJ 75-2017 and HJ 76-2017 standards, it is widely used for online measurement of flue gas humidity and oxygen to ensure compliance with environmental protection regulations.

Key Features

- High-Temperature Tolerance: The core sensor is designed with high-temperature resistance, withstanding temperatures up to 500°C, ensuring stable long-term operation in high-temperature environments.

- High-Precision Measurement: Both humidity and oxygen content are output as volume percentages. Humidity precision is ±2%F.S, and oxygen precision is ±1%F.S, meeting environmental protection technology standards.

- Strong Corrosion Resistance: Utilizing solid-state ceramic electrolytic sensor technology, the instrument offers excellent corrosion resistance, making it ideal for harsh, corrosive environments with a long service life.

- Fast Response: The response time is short, with T90 < 20 seconds, ensuring rapid and real-time data feedback.

- Convenient Calibration Function: Features a one-click calibration function for air, simplifying and improving calibration efficiency.

- Flexible Installation and Application: Supports insertion-type installation and allows for customized flange specifications and probe lengths to meet different flue gas or operational requirements.

- Multiple Calibration Functions: Supports zero point and range calibration for both oxygen and humidity, ensuring long-term stable operation.

Applications

- Environmental Protection Industry: Used in flue gas online monitoring systems, particularly for humidity and oxygen monitoring in desulfurization and denitrification processes.

- Industrial Production: Suitable for highly corrosive, harsh environments with heavy metals or toxic gas emissions, particularly in VOCs emissions monitoring.

- Energy and Chemical Industries: Provides online monitoring of humidity and oxygen in high-temperature, highly corrosive flue gases during combustion processes.

- Research and Experimentation: Used for accurate measurement of gas humidity and oxygen content in high-temperature research projects.

| Parameter | Description |

| Measurement Principle | Limiting Current Method |

| Measurement Range | H2O:0~40%VOL O2:0~25%VOL (optional) |

| Measurement Accuracy | H2O: ±2%F.S.; O2: ±1%F.S. (optional) |

| Repeatability | ±1% F.S. |

| Response Time | T90 < 20s |

| Sampling Method | Insertion Type |

| Installation Mode | Standard DN65 flange, other specifications can be customized |

| Probe Length | Standard length 800mm, other specifications can be customized |

| Flue Gas Temperature | 0250℃, 0500℃ (customizable) |

| Display Mode | LCD screen inside the instrument housing |

| Oxygen Calibration | Supports oxygen zero point and range calibration (optional) |

| Humidity Calibration | Supports humidity zero point and range calibration |

| Power Supply | 220VAC±10% 50Hz, 24W |

| Ambient Temperature | -20~50℃ |

| Ambient Humidity | 5~100%RH |

| Protection Level | IP65 |

| Storage Temperature | -40~70℃ |

| Storage Humidity | 5~95%RH |

| Power-off Protection | Power-off auto-blowback protection (optional) |

woboenerkeco

woboenerkeco