CONTACT US

Product Overview

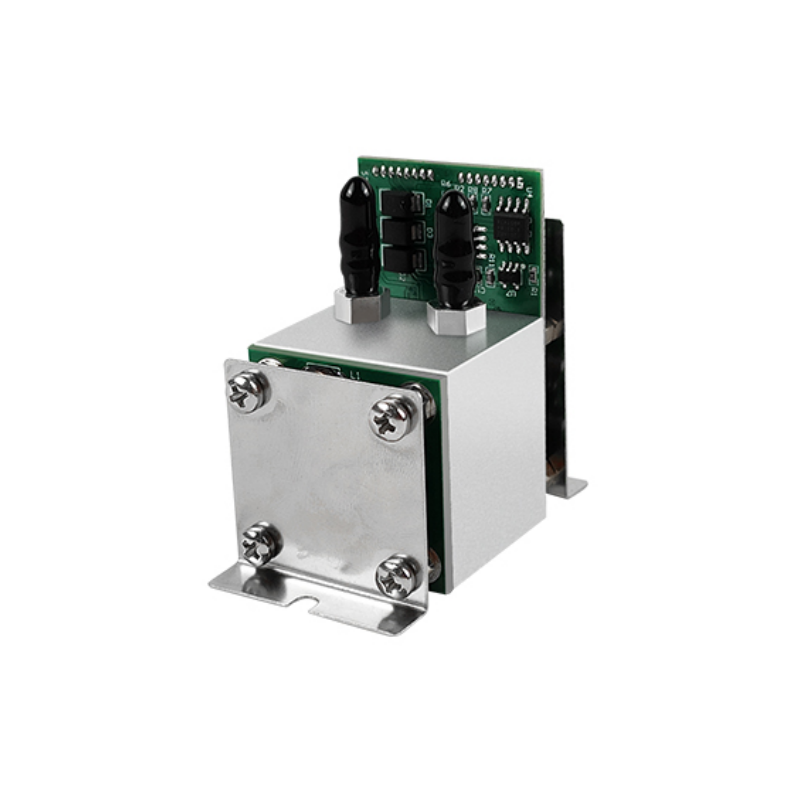

The In-Situ Laser Raman Spectroscopy Gas Analyzer uses laser Raman scattering principles with enhanced spectral technology for qualitative and quantitative analysis of multiple gas components. Designed for in-situ installation, it comes with a specialized Raman sampling probe for continuous, online, and non-destructive gas monitoring, making it ideal for comprehensive gas analysis in industrial processes. With a pressurized explosion-proof design, this device ensures safe operation, and its rapid response time of seconds allows real-time monitoring of up to 20 gas components.

Key Features

- Non-Destructive Gas Analysis: Capable of high-precision detection of homonuclear diatomic molecules like H₂, N₂, and O₂.

- Multi-Component Continuous Monitoring: Simultaneous measurement of multiple gases, supporting complex, full-process requirements.

- In-Situ Analysis Design: Raman sampling probe eliminates the need for gas extraction, directly measuring on-site and reducing maintenance costs.

- Pressurized Explosion-Proof Safety: Maintains positive pressure within the instrument to prevent entry of toxic or flammable gases, ensuring reliable operation.

- Smart User Interface: Equipped with a full touchscreen display for easy data visualization, supporting an external PC keyboard for convenience.

- Long Maintenance Cycle: No need for consumables like chromatographic columns, valves, or gas pumps, resulting in low operating costs and simple maintenance.

Applications

- Chemical Process Control: Real-time monitoring of H₂, N₂, O₂, CO, CO₂, CH₄, and other gases in chemical production.

- Environmental Protection: Monitors waste gas emissions, facilitating eco-friendly emission control.

- Oil and Gas Industry: Provides rapid detection of gas components in oil refining and natural gas processing.

- Coal Chemical and Metallurgy: Suitable for high-temperature, high-pressure gas analysis in these industries, ensuring process safety.

- Industrial Safety Monitoring: Detects toxic and flammable gas leaks in industrial settings, supporting safe production environments.

| Parameter | Description |

| Measured Components | H2, N2, O2, CO, CO2, H2S, CH4, C2H2, C2H4, C3H6, etc. |

| Measurement Range | 0~100% |

| Accuracy | ±1%F.S. |

| Repeatability | 1%F.S. |

| Input Voltage | 100~240VAC,50~60Hz (Standard) |

| Maximum Power | Less than 200W |

| Communication | RS-232/RS-485 serial, TCP/IP, USB, 4~20mA |

| User Interface | Explosion-proof touch screen |

| Dimensions (L*W*H) | 540300900 (mm) |

| Weight | 75kg |

| Number of Probes | 4 |

| Protection Level | IP65 |

| Explosion-proof Rating | Ex d ⅡC T4 Gb |

| Operating Temperature (Probe/Main Unit) | -20~600℃ (Probe), -35~40 (Analyzer) |

| Operating Humidity | 0~95% RH, non-condensing |

| Maximum Working Pressure | 4MPa |

| Fiber Cable Length | Standard 5m, customizable as needed |

woboenerkeco

woboenerkeco